A micro-laminated powder layering device

A micro-lamination and layer-up technology, applied in the direction of additive processing, can solve the problems of poor uniformity of layer thickness, low preparation efficiency, difficult to control layer thickness, etc., to achieve convenient operation, simple structure and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

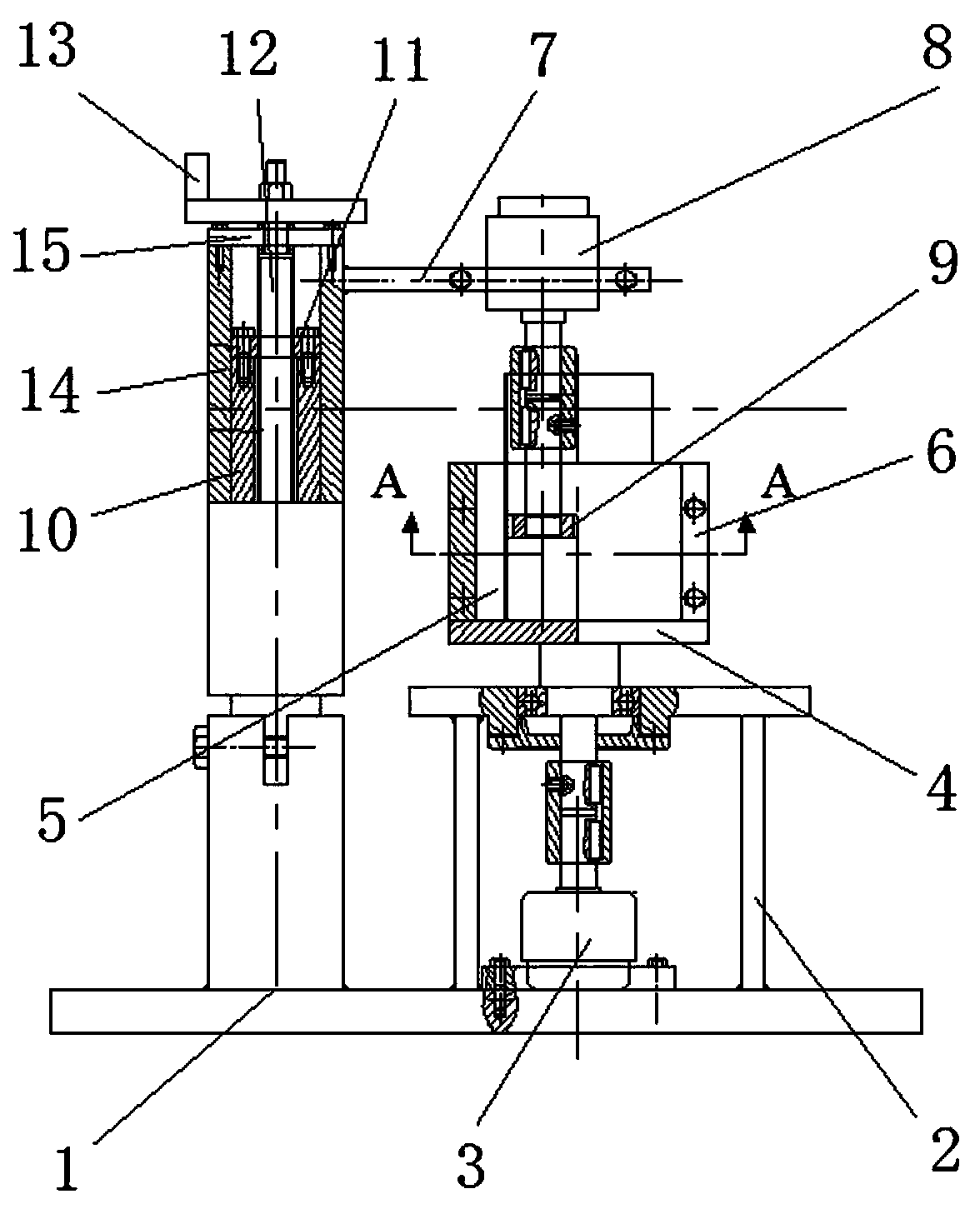

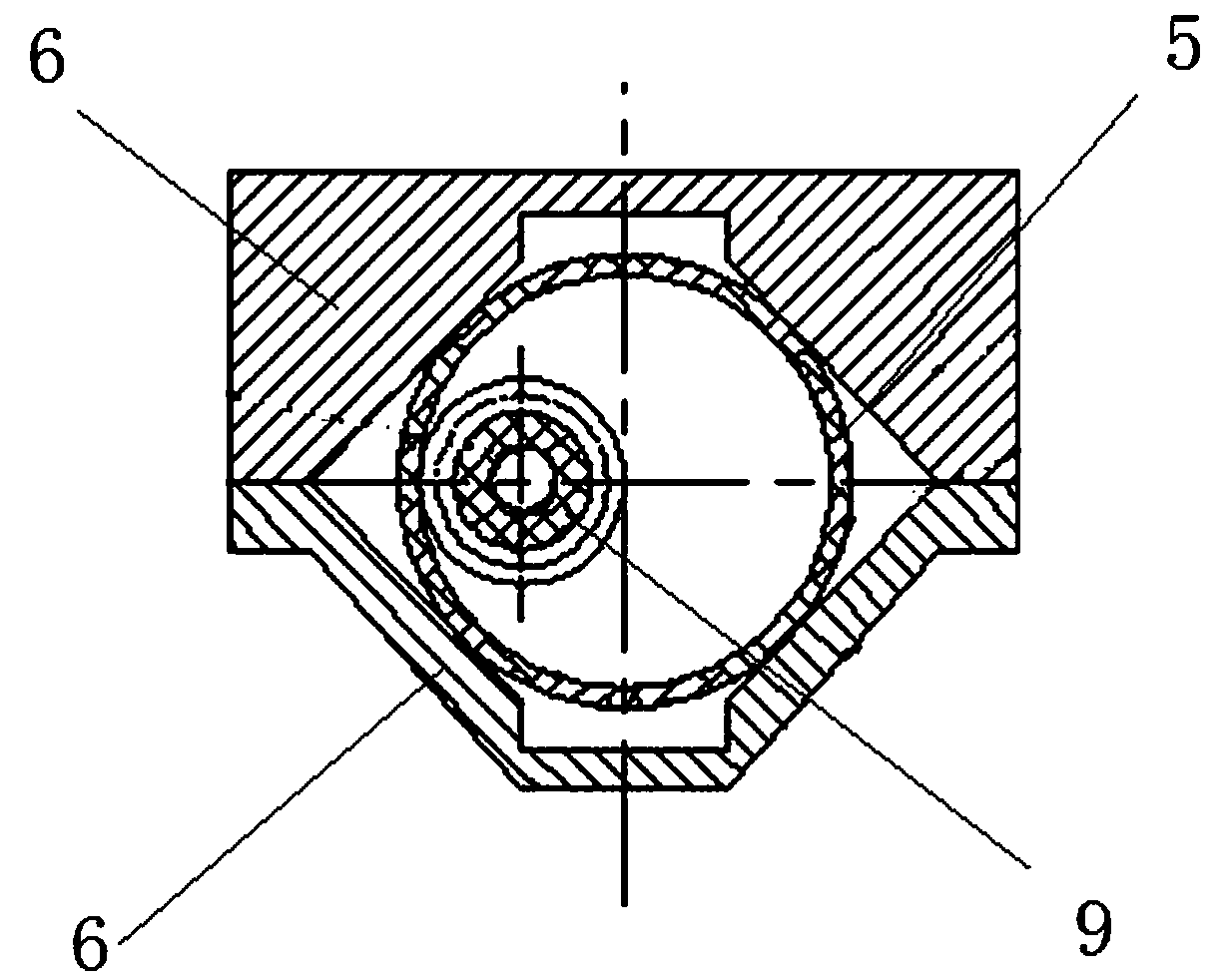

[0013] A kind of micro lamination powder laying device, comprises frame 1, and frame 1 left side is provided with lifting mechanism, and frame 1 right side is provided with platform support 2, and platform support 2 is provided with motor I3, and platform support 2 A rotary platform 4 is provided above, and the output shaft of the motor I3 is connected to the center of the rotary platform 4. A layer sleeve 5 is arranged above the rotary platform 4, and a V-shaped block 6 with two notches opposite to each other is arranged outside the layer sleeve 5. Locking bolts are arranged between the V-shaped blocks 6, and the lifting mechanism is provided with a lifting platform 7 located above the laying sleeve 5. A motor II8 is fixed on the lifting platform 7, and the output shaft of the motor II8 is connected to a The layering wheel 9 in the cylinder 5, the layering wheel 9 is close to the inner wall of the layering sleeve 5 and the diameter of the layering wheel 9 is equal to half of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com