An auxiliary device for grinding and polishing the end face of bar stock

An auxiliary device and bar technology, applied in grinding/polishing equipment, grinding machines, grinding workpiece supports, etc., can solve the problems of difficult to guarantee external force, low efficiency, inconvenience of standardization of grinding and polishing, etc., to improve grinding efficiency and ensure measurement. Error, realize the effect of standardization of grinding and polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

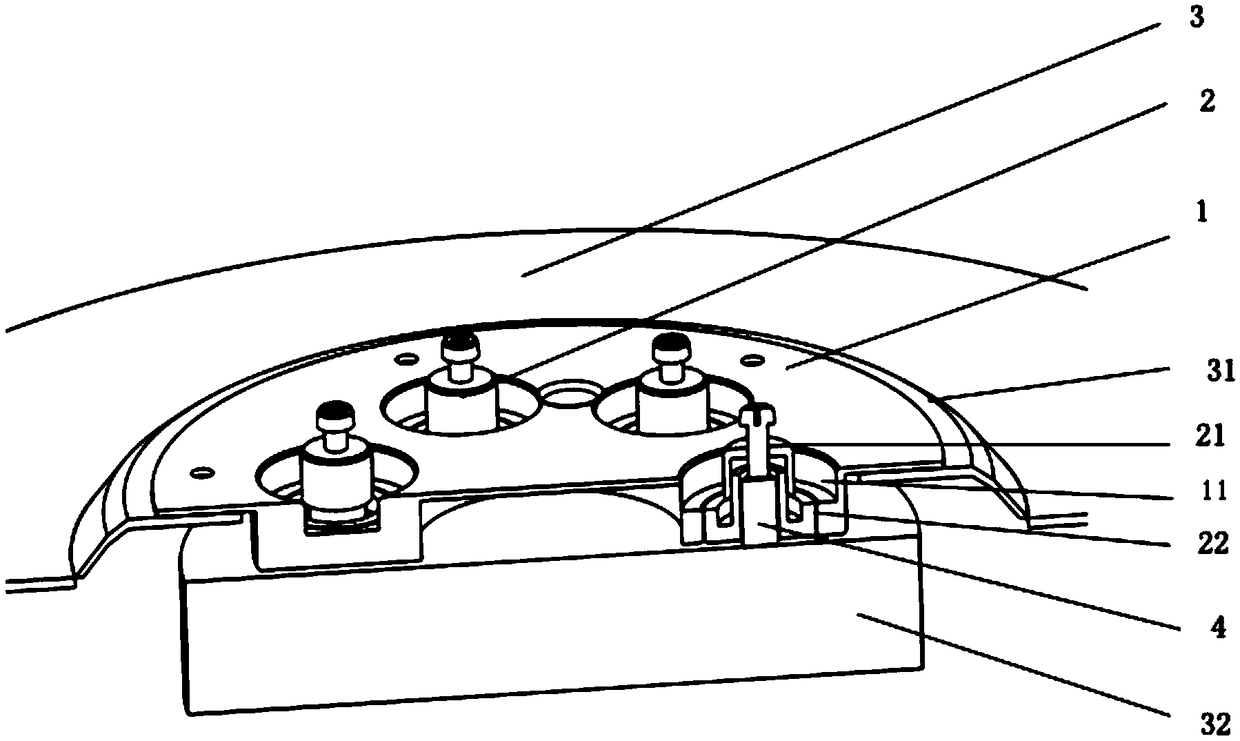

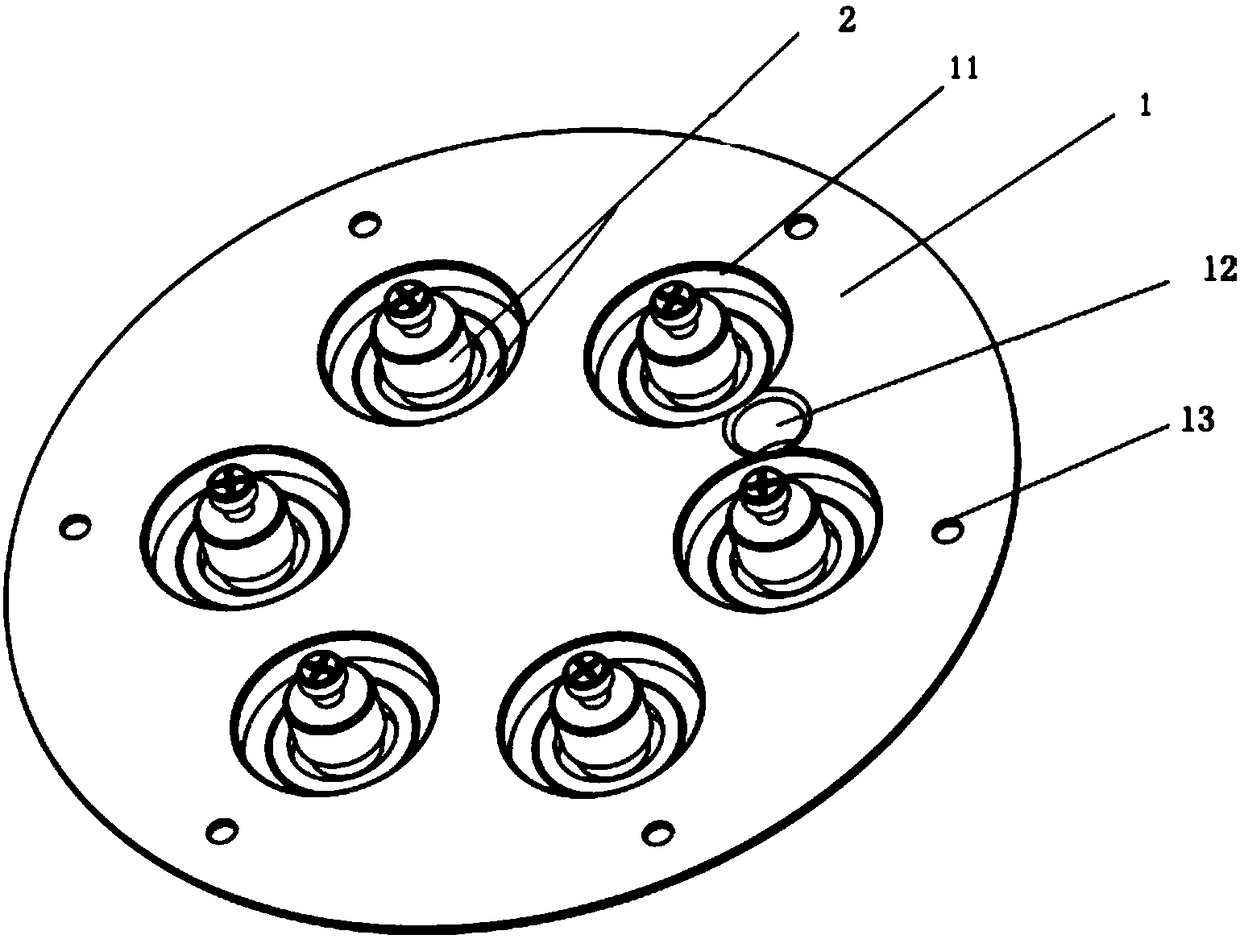

[0030] Such as figure 1 and figure 2 As shown, it is a cross-sectional three-dimensional structural schematic diagram of the assembly drawing of the auxiliary device for grinding and polishing the end surface of a glass fiber resin bar according to an embodiment of the present invention, a kind of auxiliary device for grinding and polishing the end surface of a bar, including a base 1 and a bar fixing mechanism 2; the base 1 Installed on the protective cover 31 of the rotary polishing and grinding platform 3, the center of the base 1 is symmetrically provided with at least two counterbores 11; 32 away from each other, the distance apart is far less than the length of the bar 4; the bar fixing mechanism 2 includes a bar fixing seat 22 and a pre-tightening pressing piece 21; corresponding to each of the counterbores 11, there is one bar fixing The mechanism 2 is matched with it; there is a limiting inner hole in the middle of the bar stock fixing seat 22, and the limiting inne...

Embodiment 2

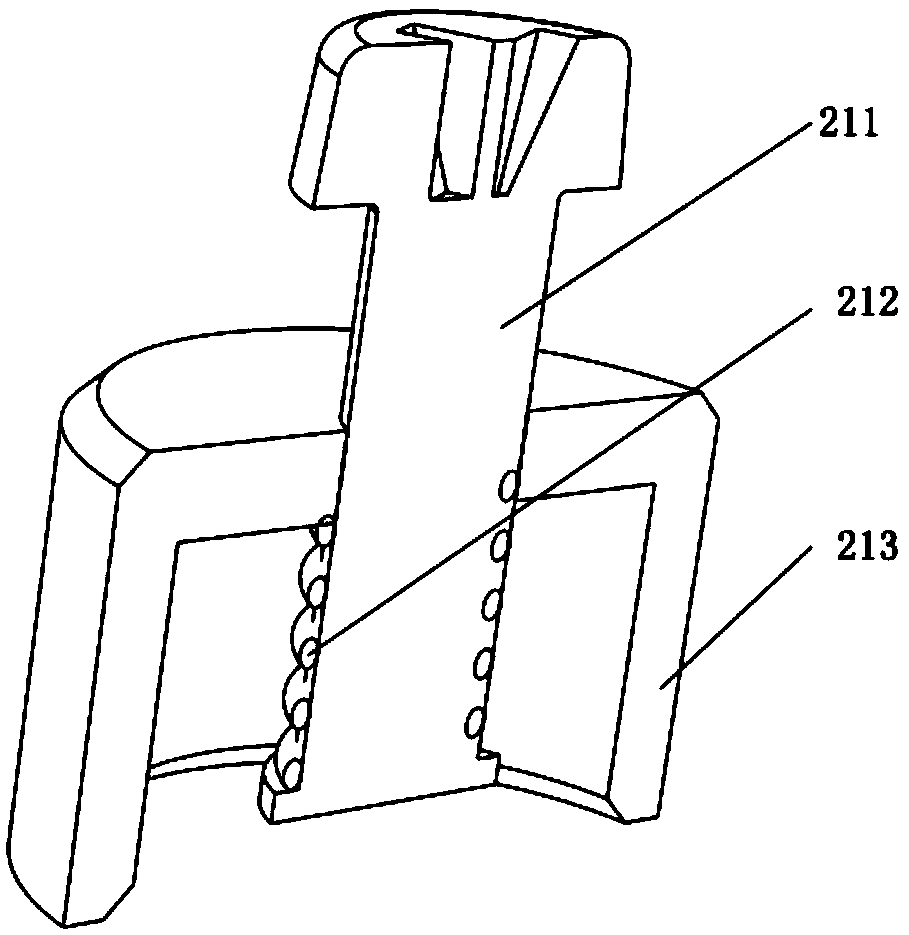

[0036] The difference from Example 1 is that, as image 3 As shown, the pre-tightening pressing part 21 includes a tightening rod 211, a damping spring 212 and a threaded connection cover 213, and the tightening rod 211 passes through the through hole at the center of the top of the screwed connection cover 213 and is connected to the top of the screwed connection cover 213. The holes are clearance fit, and the damping spring 212 surrounds the tightening rod 211 and is placed between the lower end of the top of the threaded connection cover 213 and the stepped stopper at the lower end of the tightening rod 211; by adjusting the screwed connection cover 213 The position relative to the bar stock fixing seat 22 compresses the bar stock. Preferably, the pressing rod 211 has a preloading scale corresponding to different preloading forces. Compress the bar by adjusting the relative position of the threaded connection cover 213 and the bar fixing seat 22, and at the same time obser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com