Working method of cutting tool for rearview mirror

A technology for cutting tools and rear-view mirrors, which is applied in the direction of manufacturing tools, metal processing equipment, abrasive feeding devices, etc., can solve the problems of complex structure and inconvenient use, and achieve the effect of simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

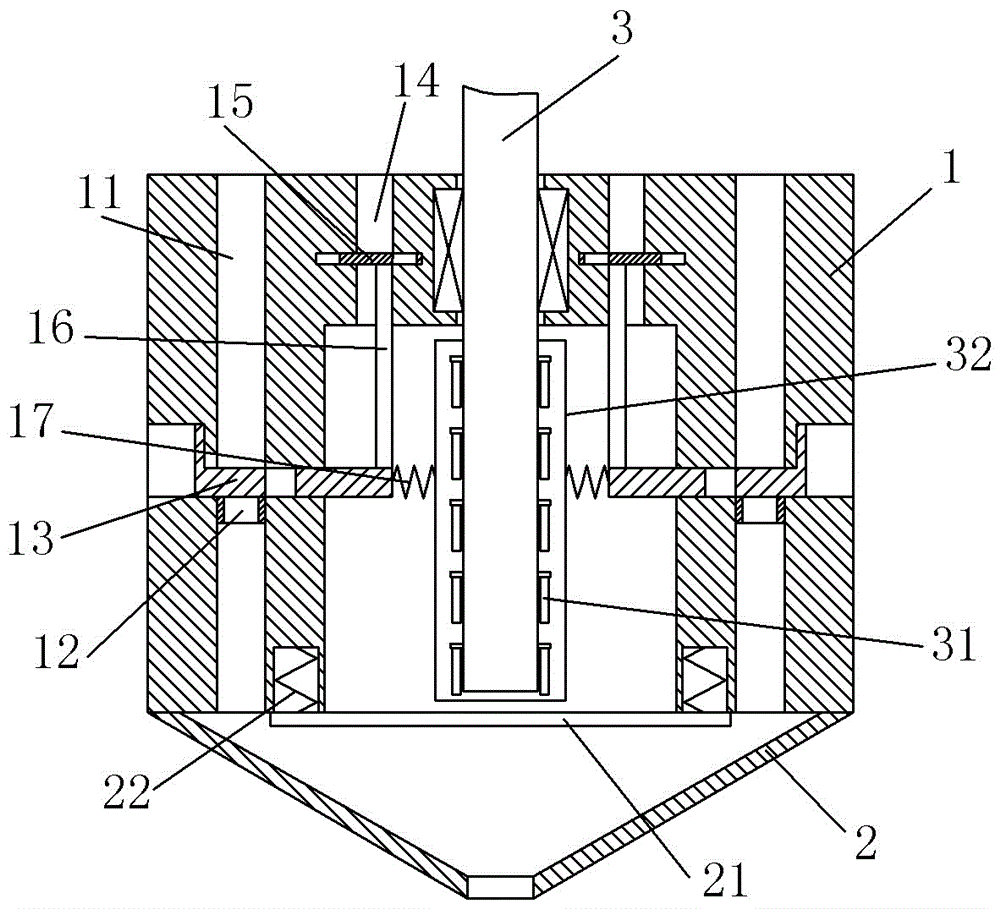

[0022] The reference signs in the drawings of the description include: nozzle seat 1, sand inlet hole 11, first filter hole 12, second filter plate 13, water inlet hole 14, water passing plate 15, connecting plate 16, second spring 17, Nozzle 2 , partition 21 , first spring 22 , rotating shaft 3 , support rod 31 , elastic member 32 .

[0023] The cutting tool used in this program is as attached figure 1 As shown: including the rotating shaft 3 and the nozzle, the nozzle includes the nozzle seat 1 and the nozzle 2, the working chamber is formed between the nozzle seat 1 and the nozzle 2, the nozzle 2 is a conical nozzle 2, and the upper end of the nozzle 2 is a large cone-shaped structure End, the nozzle 2 is provided with a tapered spray hole, the upper end of the spray hole is also the large end of the tapered structure.

[0024] A partition 21 is arranged in the worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com