Novel claw hammer

A claw hammer and a new type of technology, applied in the field of hardware tools, can solve the problems of small size of claw hammer and wrench, waste of time to find and use, reduce work efficiency, etc., and achieve the effect of providing work efficiency, saving time, and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

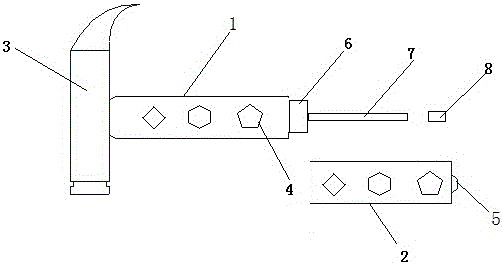

[0017] Example: such as figure 1 As shown, a new type of claw hammer includes a handle and a hammer body 3. The handle adopts a detachable design and is divided into two parts, the front handle 1 and the rear handle 2. One end of the front handle 1 is fixedly connected with the hammer body 3, and the front The handle 1 and the rear handle 2 are flat and hollow structures. The surfaces of the front handle 1 and the rear handle 2 are provided with multiple forks 4 for rotating the screw cap. The front handle 1 and the rear handle 2 are connected by threads, and the tail end of the front handle 1 has The protruding part 6 extending out of the body is provided with an external thread on the outside of the protruding part 6, and the middle position of the protruding part 6 is fixed with a screwdriver rod 7, the tail of the screwdriver rod 7 is connected to the screwdriver head 8, and the rear handle 2 is connected to the front handle 1. The inner wall of the opening at one end is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com