Integral transfer straddle-type monorail PC track beam template

A straddle-type monorail and track beam technology, applied in the direction of molds, mold auxiliary parts, etc., to facilitate manufacturing and improve manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

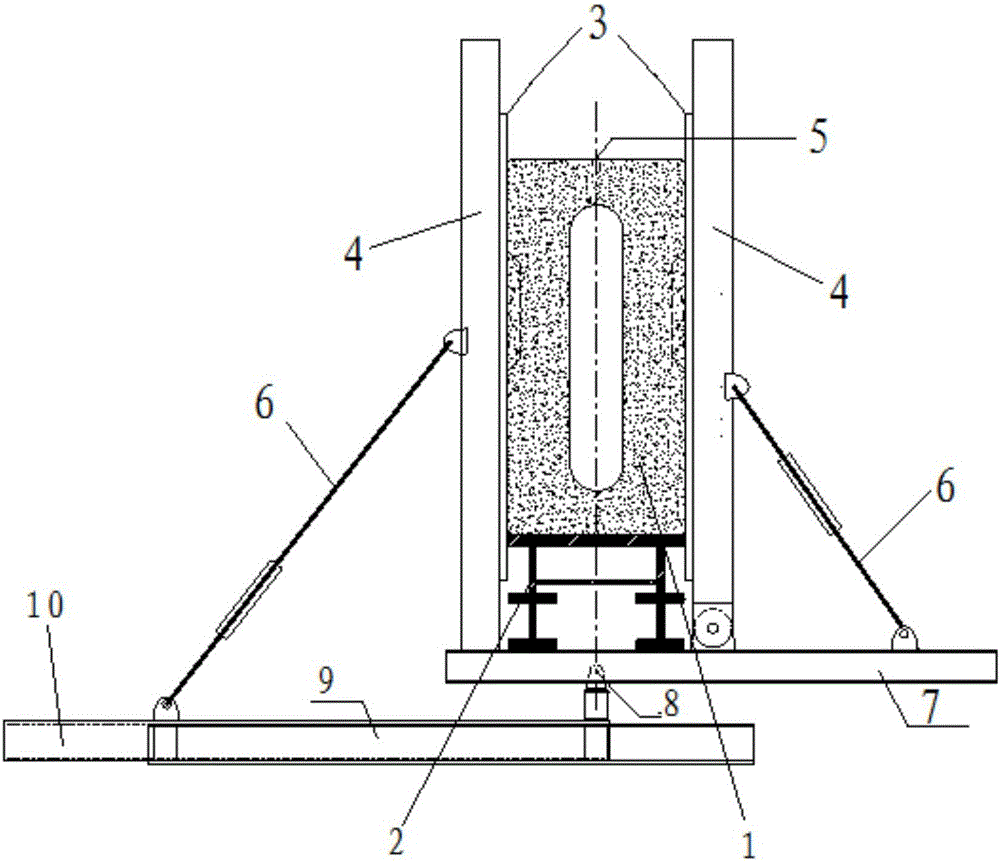

[0022] The present invention will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

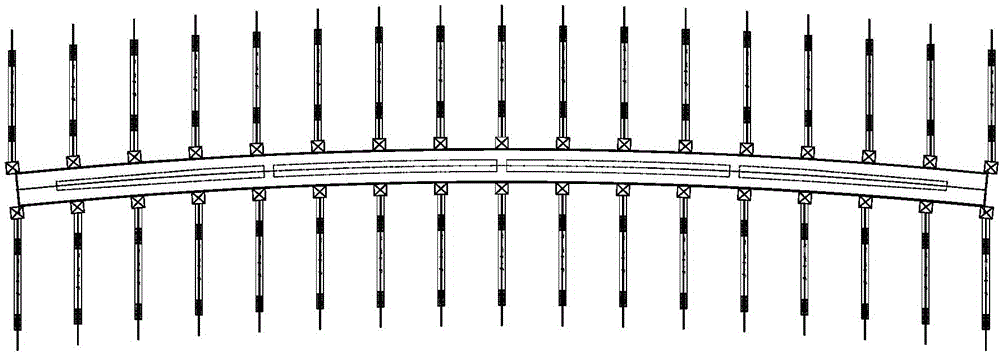

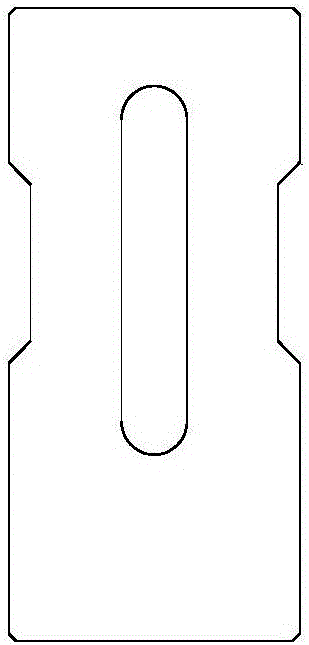

[0023] Considering that the existing formwork system has single applicability and is only suitable for PC beams of equal height, an integrally transferable straddle-type monorail PC track beam formwork is proposed. The formwork system can be used to prefabricate and produce large, medium and small-sized straight curved PC track beams of equal height and variable height within 30m. At the same time, when the control elevation of the top surface of the longitudinal center line of the bottom of the beam is determined, the template can be rotated as a whole to form the required track alignment, which improves the operability and efficiency of the beam body during beam manufacturing. If the cross-section of the beam remains unchanged (such as image 3 , Figure 5 (shown) only forms the linear shape required by the curve by the way of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com