An antibacterial plastic wrap

A technology of fresh-keeping film and film layer, applied in the field of fresh-keeping materials, can solve the problems of not being able to prevent bacterial erosion, etc., and achieve the effects of avoiding water loss, eliminating ethylene, and alleviating self-consumption of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

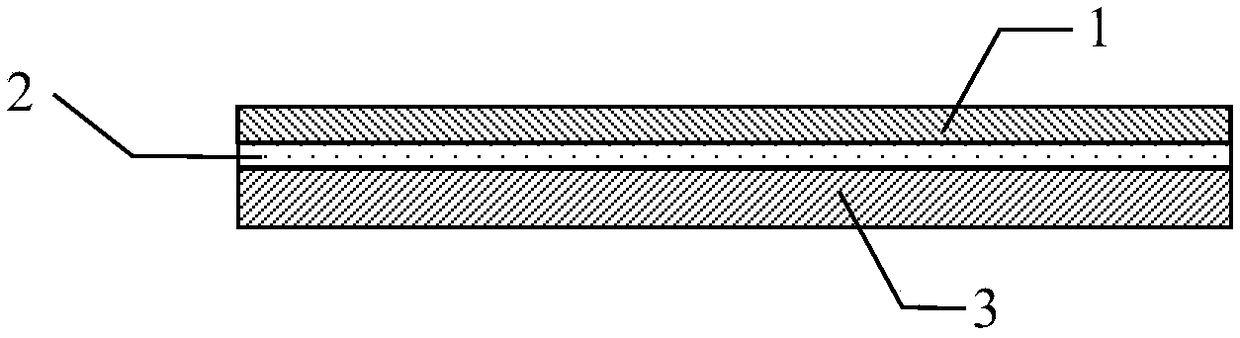

Image

Examples

preparation example Construction

[0032] The present invention has no special limitation on the preparation method of the antibacterial fresh-keeping film, and the preparation method of the fresh-keeping film well-known to those skilled in the art can be adopted. In the present invention, the preparation of described antibacterial fresh-keeping film preferably comprises the following steps:

[0033] Mixing at least one of the back layer base material, the middle layer base material and the surface layer base material with the negative ion material respectively, and extruding it as a raw material to obtain an antibacterial fresh-keeping film;

[0034] Or use the back layer substrate, the middle layer substrate and the surface layer substrate as raw materials, extrude to obtain a multilayer film, and then spray the negative ion material on the inner surface and / or outer surface of the multilayer film to obtain an antibacterial fresh-keeping film;

[0035] Or mix at least one of the back layer base material, the ...

Embodiment 1

[0039] Mix polyethylene and negative ion material as the back layer material, polyvinyl chloride as the middle layer material, polypropylene as the surface layer material, and the content of the negative ion material is 5%, to prepare an antibacterial fresh-keeping film;

[0040] The negative ion material includes zirconium dioxide, lutetium oxide, tourmaline and lanthanum oxide in a mass ratio of 10:1:10:0.5.

[0041] The antibacterial preservative film prepared in this example has an anion release rate of 9000 / cm 2 / min.

Embodiment 2

[0043] Polyethylene is used as the material of the back layer, polyvinyl chloride is used as the material of the middle layer, polypropylene and anion material are mixed as the surface layer material, and the content of the anion material is 1%, and an antibacterial fresh-keeping film is prepared.

[0044] The negative ion release rate of the antibacterial plastic wrap prepared in this example is 1000 / cm 2 / min;

[0045] The negative ion material includes zirconium dioxide, lutetium oxide, tourmaline and lanthanum hydroxide in a mass ratio of 1:5:10:10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com