Air pressure balancing device and method for ink cartridge of inkjet printer

An air pressure balance, inkjet printer technology, applied in printing and other directions, can solve the problems of explosion, ink cartridge deformation, affecting the fluency and stability of the inkjet printer printing process, etc., to improve sealing reliability, smooth process, and improve convenience. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

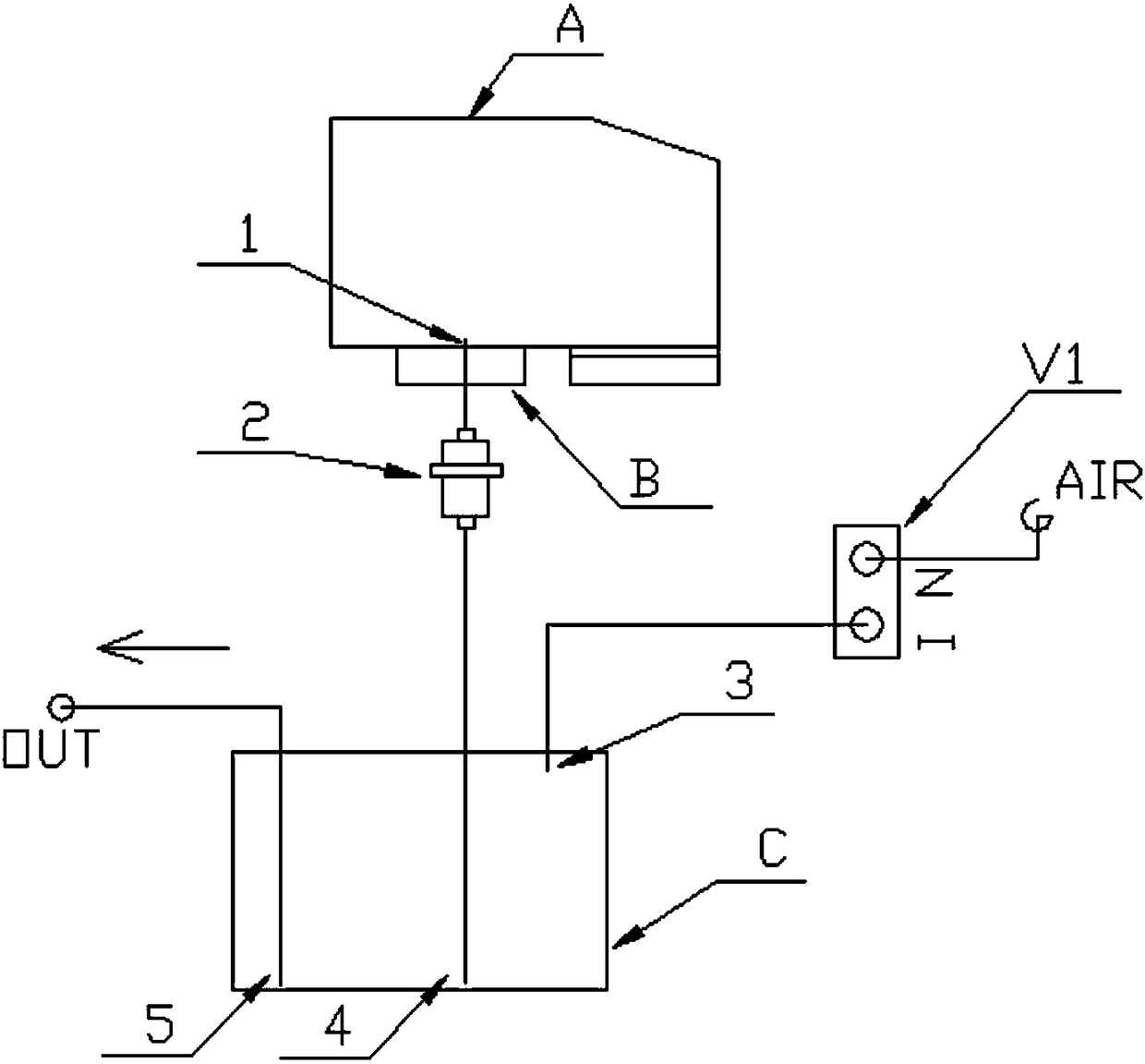

[0037] An air pressure balance device for an ink cartridge of an inkjet printer, comprising a buffer chamber C and an ink cartridge A. An ink outlet is provided at the bottom of the ink cartridge A, and the ink outlet is sealed by a solid rubber plug B. The buffer cabin C includes a buffer cabin main body, an exhaust pipe 3 , a balance pipe 4 and an extraction pipe 5 , and the buffer cabin C main body is a closed container. One end of the balance tube 4 leads into the bottom of the inner cavity of the buffer chamber C, and the other end is integrally connected with the stainless steel fine needle tube 1 to form a connected body between the buffer chamber C and the ink cartridge A. One end of the exhaust pipe 3 communicates with the top of the inner cavity of the buffer cabin C, and the other end is provided with a normally open valve V1. The chamber pressure is in balance with the external atmospheric pressure. That is, when the normally open valve V1 is de-energized, the con...

Embodiment 2

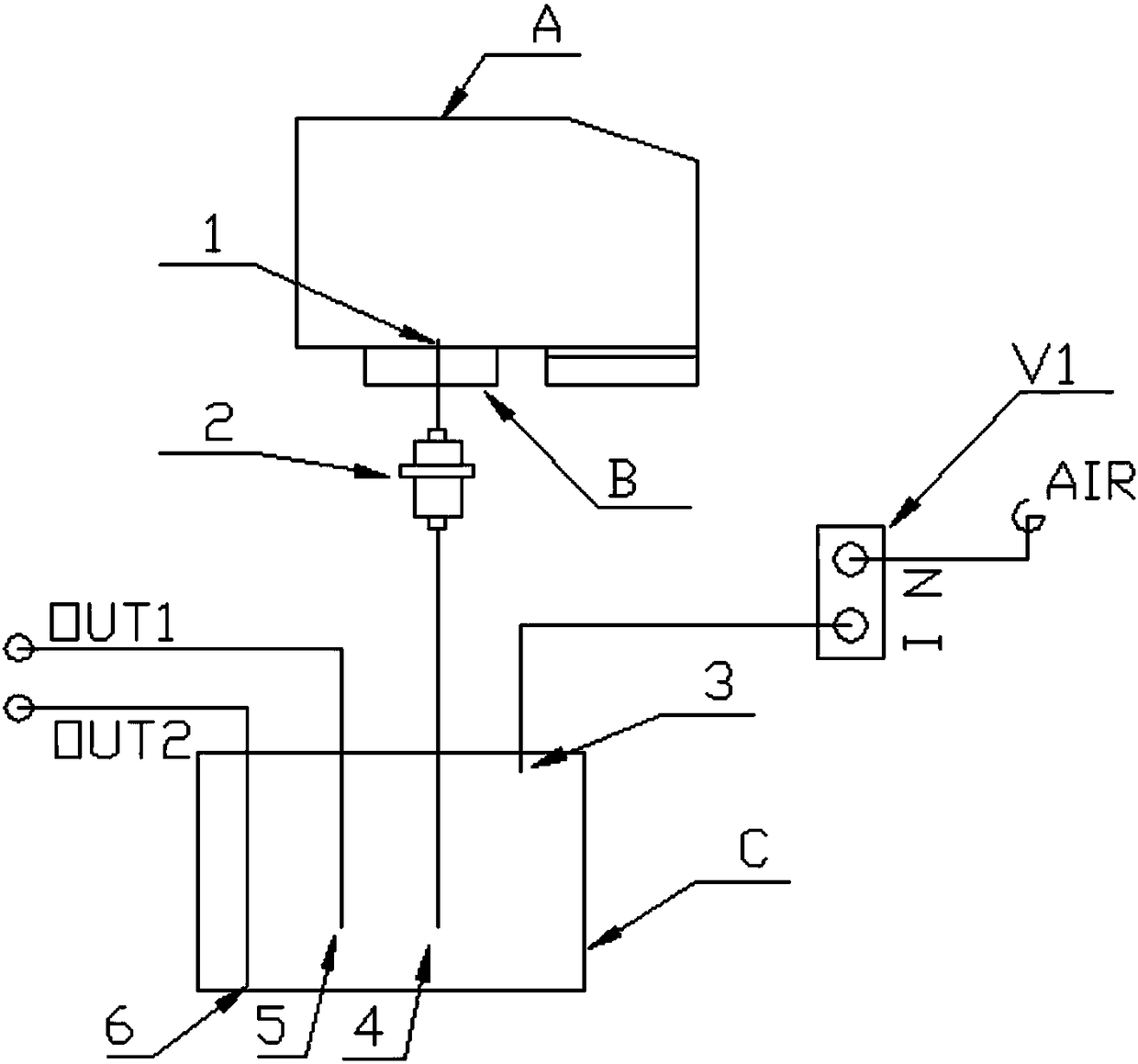

[0041] In this embodiment, the ink cartridge A is used to contain the solvent used for cleaning the pipeline, so it is called solvent cartridge A in this embodiment. It includes a buffer cabin C and a solvent box A. A solvent outlet is provided at the bottom of the solvent box A, and the solvent outlet is sealed by a solid rubber plug B. The buffer cabin C includes a buffer cabin main body, an exhaust pipe 3 , a balance pipe 4 , an extraction pipe 5 and a solvent extraction pipe 6 , and the main body of the buffer cabin C is a closed container. One end of the balance tube 4 leads to the bottom of the inner cavity of the buffer cabin C, and the other end is integrally connected with the stainless steel fine needle tube 1 to form a connected body between the buffer cabin C and the solvent box A. One end of the exhaust pipe 3 communicates with the top of the inner cavity of the buffer cabin C, and the other end is provided with a normally open valve V1. The chamber pressure is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com