Lead screw assembling device, engraving and milling machine and lead screw adjusting method

A technology for assembling device and screw rod, which is applied to transmission devices, decorative arts, mechanical equipment, etc., can solve the problems of difficult maintenance and high cost, and the process of adjusting screw assembly accuracy is cumbersome, and achieves simple structure, easy maintenance, and convenient adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

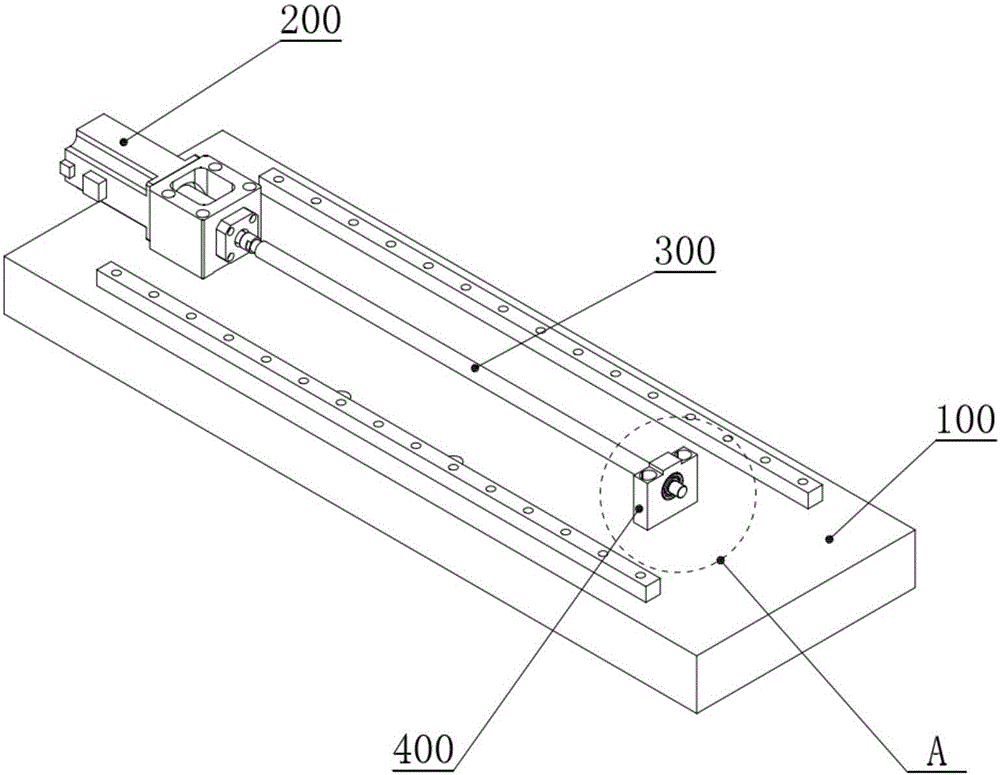

[0037] The invention provides a screw rod assembly device, such as Figure 3-5 As shown, it includes a support seat 1, a bearing fixing seat 2, a support bearing assembly 3 and at least two positioning pins 4. The support base 1 is arranged opposite to the motor 200 that drives the screw rod 300 to rotate, and is fixedly installed on the fixed base 100 . Specifically, the support base 1 is vertically installed on the fixed base 100 by bolts. The above-mentioned bearing fixing base 2 is movably installed on the support base 1 . The above-mentioned support bearing assembly 3 is fixedly sleeved on one end of the screw rod 300 not connected to the motor 200, and is fixedly installed on the bearing holder 2, which can be driven by the bearing holder 2 to adjust the position, and then driven by the beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com