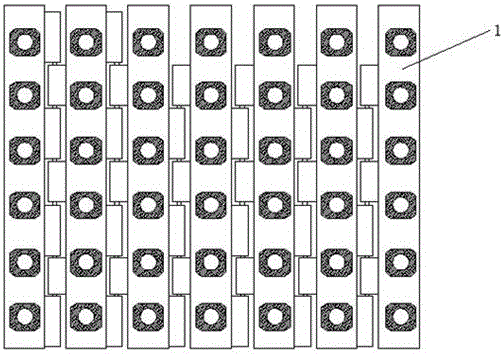

Mesh belt type distributing and combining device

A mesh belt type and mesh belt technology, applied in the field of conveyor belts, can solve the problem of no mesh belt type shunting and confluence devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

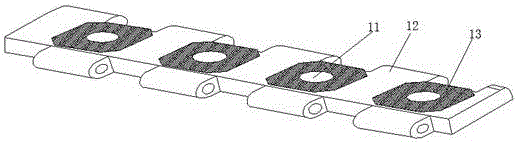

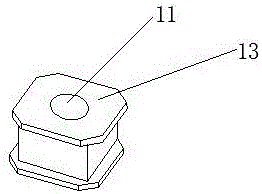

[0022] Embodiment 1: Using this design of the mesh belt type diversion and confluence device, the driver is installed at the bottom, in a dynamic friction mode; the universal ball 11 is at right angles to the direction of travel of the conveyor belt, and when the conveying object arrives within the range of the driver installation , the products on the conveyor belt surface will be transferred to the left and right sides to realize the transportation planning of distribution, sorting and other logistics.

Embodiment 2

[0023] Embodiment 2: Using this design of the mesh belt type diversion and confluence device, a static friction device is installed at the bottom, and the universal ball 11 passing through this area will move at double speed, which can achieve the effect of pulling the conveyed objects apart ; On the contrary, if it is blocked in the front section, the distance between products will be shortened due to multiple movements.

Embodiment 3

[0024] Embodiment 3: The mesh-belt-type shunting and merging device with this design is installed at the bottom parallel to the conveyor belt, and the drivers on the left and right sides operate symmetrically. When the universal ball 11 on the conveyor belt touches this area At this time, the product will rotate more than 90 degrees on the conveyor belt, which is suitable for the current directional requirements of product transportation, job diversion, and sorting requirements. It is very suitable for the work in the pre-operation section such as reversing, aligning, and pushing before the palletizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com