Automatic cargo unloading system and method thereof

An automatic unloading and cargo technology, which is applied in the field of logistics, can solve the problems of cargo damage and unable to automatically unload packages, etc., and achieve the effects of reducing excessive height difference, ensuring safety, and reducing the possibility of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

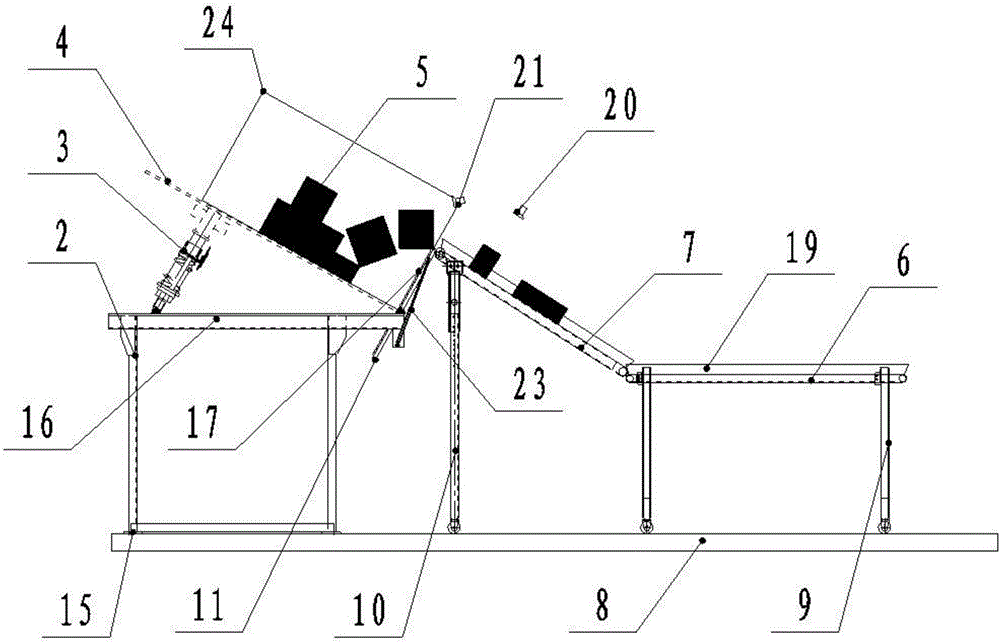

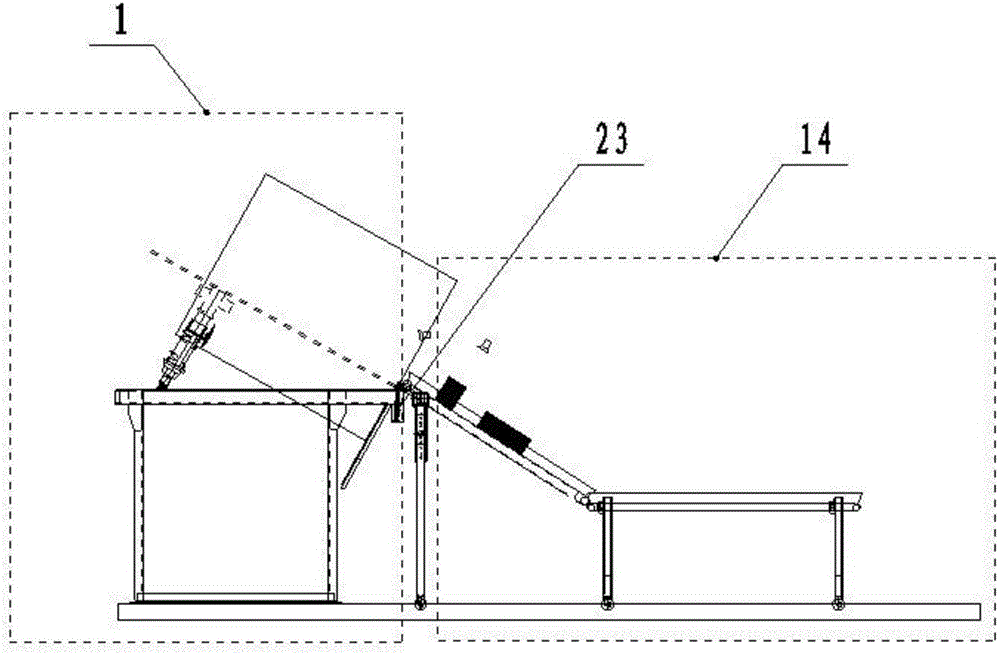

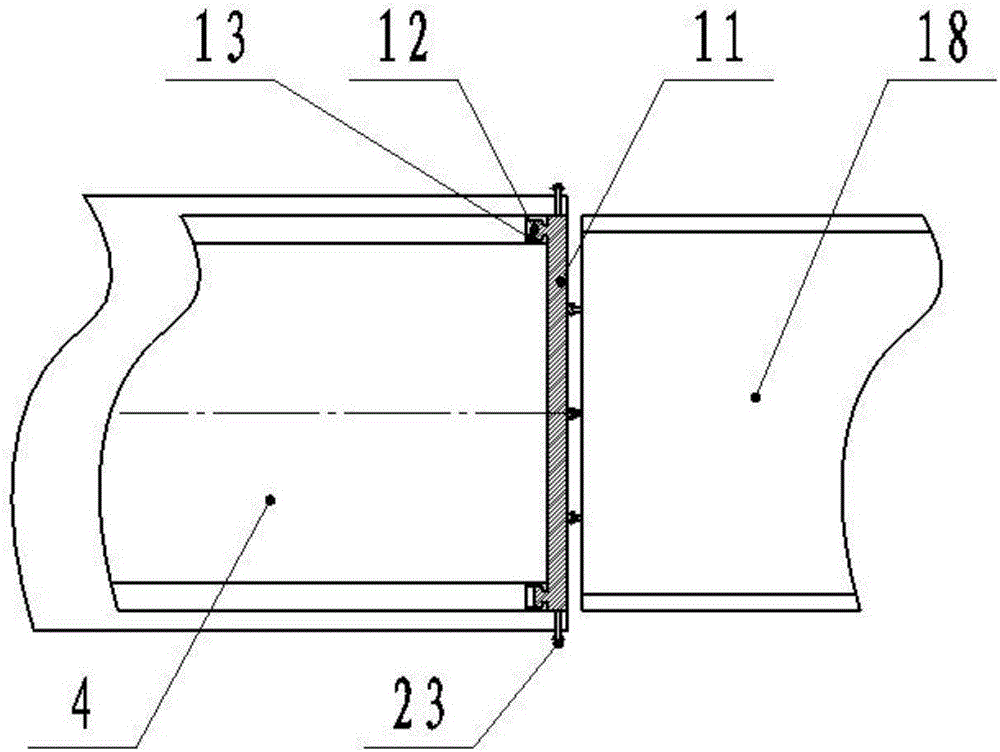

[0037] like Figure 1-4As shown, an automatic cargo unloading system of the present invention includes a turning assembly 1 and a conveyor belt assembly 14. The turning assembly 1 includes a base 2, a turning hydraulic cylinder 3 and a box fixing turning frame 4. The box fixing turning frame 4 is based on actual needs. It can be improved on the cargo box 24 on the existing truck, or a reverse L shape formed by a bottom plate and a fixed frame can be used, and the cargo box 24 on the truck can be transferred and transported on the box fixing and turning frame 4, and the box body is fixed. The bottom corner of the front end of the flip frame 4 is hinged on the top of the front end of the base 2, and several hinge brackets are used between the bottom corner of the front end of the fixed flip frame 4 and the top front of the base 2 to ensure that the fixed flip frame 4 is stable during flipping. A turning hydraulic cylinder 3 is arranged between the bottom surface of the rear end ...

Embodiment 2

[0043] like Figure 1-4 As shown, the present invention is an automatic cargo unloading system. On the basis of Embodiment 1, some automatic functional components are added to the automatic cargo unloading system, so that the loading and unloading system is more automated, such as Figure 4 It is a schematic diagram of the principle of unloading controlled by the controller of the present invention; for example, a first sensor 20 for monitoring the size, arrangement and movement speed information of the package 5 is provided above the elevating conveyor belt assembly 7, and a side above the rear end of the elevating conveyor belt assembly 7 is provided with A second sensor 21 for monitoring the quantity, arrangement and movement speed information of the packages 5 in the box. The positions of the first sensor 20 and the second sensor 21 are relatively fixed relative to the lifting conveyor belt assembly 7, and move with the movement of the lifting conveyor belt assembly 7, whi...

Embodiment 3

[0047] like Figure 1-4 As shown, an automatic unloading method of the present invention includes the steps:

[0048] Step 1) Assemble the automatic cargo unloading system, connect the turning assembly 1 to the conveyor belt assembly 14, the slider 12 of the telescopic door 11 is inserted into the chute 13 on the front side of the box fixing turning frame 4, and the cargo box 24 is fixed On the box body fixed flip frame 4;

[0049] Step 2) Operating the controller 22 to control the lifting of the overturning hydraulic cylinder 3 to drive the box-fixed overturning frame 4 to overturn and unload, and at the same time, the controller 22 controls the telescopic door to control the hydraulic cylinder 23 to open the telescopic door 11;

[0050] Step 3) The first sensor 20 controls the jacking speed of the overturning hydraulic cylinder 3 by unloading the package on the conveyor belt of the lifting conveyor belt assembly 7;

[0051] Step 4) The package unloaded on the conveyor belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com