Nano-silica sol with novel structure

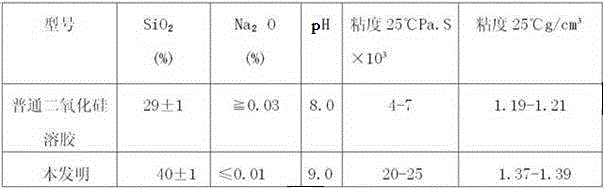

A nano-silica and nano-titanium dioxide technology, applied in the field of nano-silica sol, can solve the problems of uncontrollable particle size, unclear interface between particles, uncontrollable shape, etc., and achieve low cost, high mechanical strength, The effect of less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

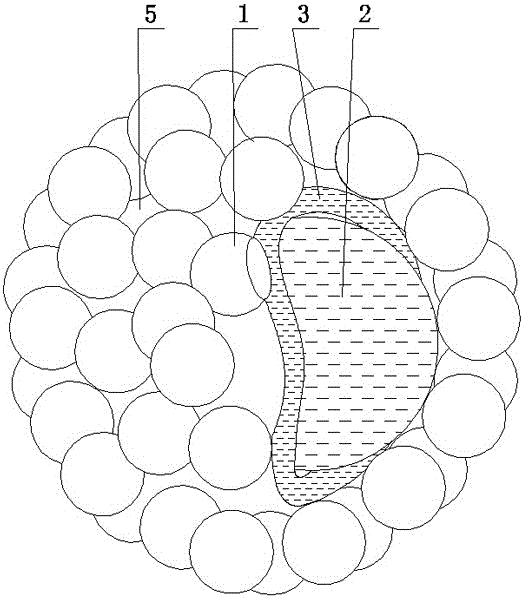

[0017] figure 1 It is a schematic diagram of the structure of nano-silica sol with a new structure, which is composed of figure 1 It can be seen that the shape of the material is spherical, including a three-layer composite capsule structure, wherein the innermost layer is a nano-titanium dioxide core 2, and the titanium dioxide core 2 is wrapped with a sodium metaaluminate capsule wall 3, and the diameter of the sodium metaaluminate capsule wall is 50- 100nm. The outermost layer of the capsule wall 3 coated with sodium metaaluminate is the capsule wall 1 composed of nano-silica sol, the diameter of the nano-silica particle is 20-24nm, and the diameter of the capsule wall 1 is 100-150nm. A plurality of nanoscale micropores 5 are arranged on the wall 1 of the nano silicon dioxide soluble capsule.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com