Multipoint water-in sludge in-situ reduction synchronous coupling nitrogen and phosphorus removal method

A synchronous coupling, denitrification and dephosphorization technology, applied in the direction of water/sludge/sewage treatment, water pollutants, biological sludge treatment, etc., can solve the problem that sludge cannot be reduced in situ, so as to reduce infrastructure investment and improve Effect of Nitrogen and Phosphorus Removal Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

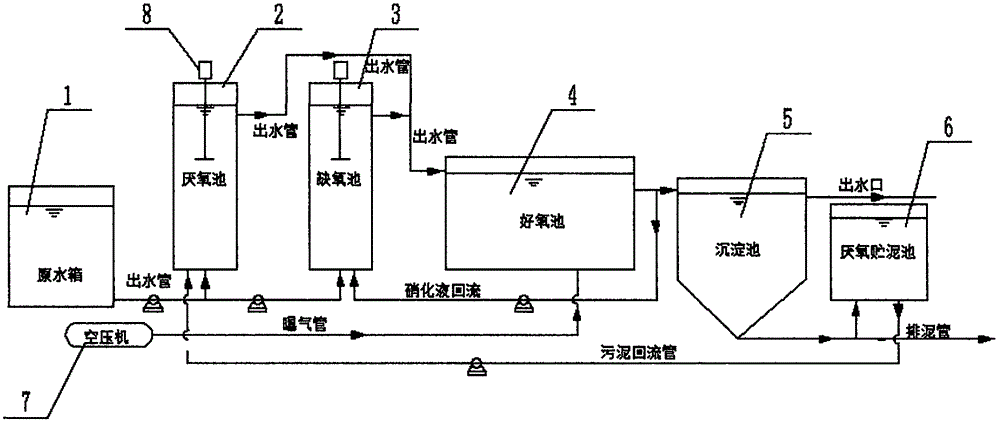

[0022] Step 1, the raw sewage enters the anaerobic pool 2 and the anoxic pool 3 according to the volume distribution ratio of 5:5, and the raw sewage CODCr concentration, TN concentration, NH3-N concentration, TP concentration, water temperature, anaerobic pool 2 and anoxic pool The HRT of Pool 3 was determined to be 396mg / L, 36mg / L, 34mg / L, 3mg / L, 28°C, 1.89h, and 0.94h, respectively;

[0023] Step 2, the aerobic pool 4 receives the mud-water mixture discharged from the anaerobic pool 2 and the anoxic pool 3, and the HRT, DO concentration and temperature of the aerobic pool 4 are respectively determined to be 1.85h, 2mg / L and 28°C;

[0024] Step 3, the mud-water mixture discharged from the aerobic tank 4 enters the sedimentation tank 5 and the anoxic tank 3 respectively according to the volume distribution ratio of 1:2.5, and the sedimentation time of the sedimentation tank 5 is determined to be 1 hour;

[0025] Step 4: After the mud-water separation is carried out in the sed...

Embodiment 2

[0029] Step 1, the raw sewage enters the anaerobic pool 2 and the anoxic pool 3 according to the volume distribution ratio of 5:5, and the raw sewage CODCr concentration, TN concentration, NH3-N concentration, TP concentration, water temperature, anaerobic pool 2 and anoxic pool The HRT of Pool 3 was determined to be 512mg / L, 64mg / L, 52mg / L, 9mg / L, 28°C, 1.89h, and 0.94h, respectively;

[0030] Step 2, the aerobic pool 4 receives the mud-water mixture discharged from the anaerobic pool 2 and the anoxic pool 3, and the HRT, DO concentration and temperature of the aerobic pool 4 are respectively determined to be 1.85h, 2mg / L and 28°C;

[0031] Step 3, the mud-water mixture discharged from the aerobic tank 4 enters the sedimentation tank 5 and the anoxic tank 3 respectively according to the volume distribution ratio of 1:2.5, and the sedimentation time of the sedimentation tank 5 is determined to be 1 hour;

[0032] Step 4: After the mud-water separation is carried out in the sed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com