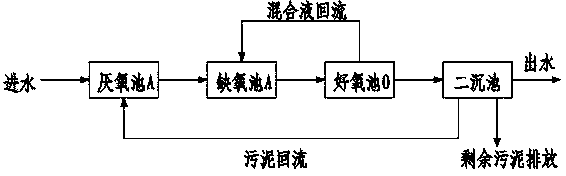

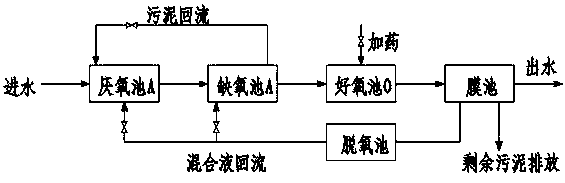

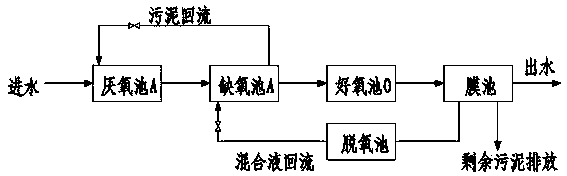

A<2>/O and MBR combined sewage regenerating process and device

A regeneration device and sewage technology, which is applied in the field of water treatment, can solve the problems of difficult biological treatment, low nitrogen and phosphorus removal efficiency, and high self-control requirements, to achieve enhanced biological nitrogen and phosphorus removal functions, increase operational flexibility, and operate Good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Taking the influent of a sewage treatment station in the core area of a new city as an example after pretreatment (mechanical grille, regulating tank, membrane grille), the influent COD, ammonia nitrogen and total phosphorus values (COD= 100-400mg / L, ammonia nitrogen= 10-40mg / L, TP=2.5-3.5mg / L). The hydraulic retention time (HRT) of the deaerobic, anaerobic, anoxic and aerobic zones are 0.5h, 1h, 2.5h and 3h respectively, the mixed liquor reflux ratio is 200%, and the sludge reflux ratio is 100%. When the sewage water temperature is higher than 15°C, run the biological denitrification and phosphorus removal mode to carry out biological nitrogen and phosphorus removal; when the water temperature is ≤15°C, run the biological denitrification mode and add 30mg / L aluminum sulfate to the aerobic pool. The MBR membrane bioreactor uses hollow fiber membrane modules. The effluent of the treatment device meets the water quality standards for urban greening water and toilet f...

Embodiment 2

[0029] Example 2 is a reclaimed water treatment station project in a scenic lake. The difference from Example 1 is that a deep chemical phosphorus removal process is added after the MBR membrane bioreactor exits the water, and the dosage of polyaluminum chloride is 30mg / L; the water temperature is ≤15°C When running the denitrification mode, add 20mg / L polyaluminum chloride to the aerobic tank. Depth filtration adopts active sand filter, and the selected filtration speed is 5m 3 / (m 2 . Due to the addition of a deep chemical phosphorus removal process, the effluent after treatment meets the "Water Quality of Urban Sewage Recycling Landscape Environment" (GB / T 18920-2002) standard.

[0030] It can be concluded from Examples 1 and 2 that after sewage regeneration treatment by this process, the effect of nitrogen and phosphorus removal is good, the process operation flexibility is high, and the effluent quality can reach the water quality standard of urban miscellaneous water; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com