Device and method for removing nitrate from water body based on biofilm reactor

A technology of biofilm reactor and membrane reactor, which is applied in chemical instruments and methods, water pollutants, energy wastewater treatment, etc., can solve the problems of increased operating costs, ineffective nitrate removal, and low denitrification activity. Achieve the effect of reducing operating costs, easy installation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This example illustrates a specific implementation of the device of the present invention.

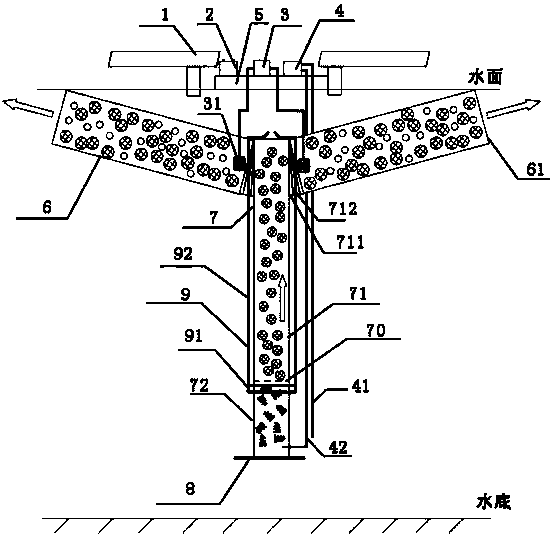

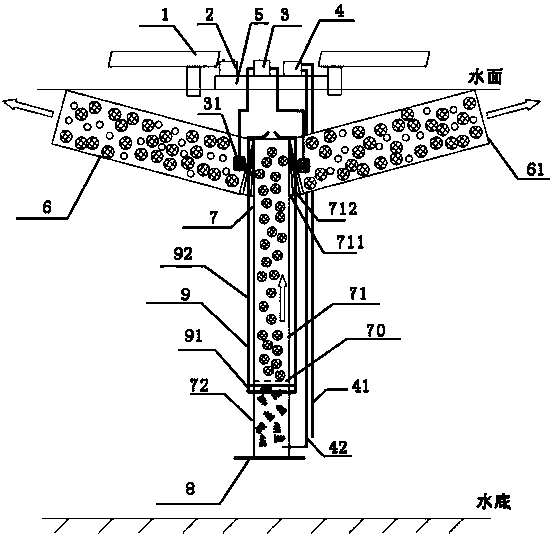

[0034] Such as figure 1 The shown device for removing nitrate from water based on biofilm reactor includes a power device and a reaction device;

[0035] The power unit is located above the water surface and is placed on the water floating platform 5, including an air pump 3, a water pump 4 and an energy supply device for providing energy for the air pump 3 and the water pump 4; in this embodiment, the solar function is adopted, and the energy supply device includes a solar panel 1 and battery 2.

[0036] The reaction device is located at the lower part of the water surface, and includes an aerobic biofilm reactor 6, an anaerobic biofilm reactor 7, and a reactor base 8 from top to bottom; anaerobic biofilm reactor 7 and an aerobic biofilm reactor 6 is a cylindrical structure, and the material is selected from plexiglass. The anaerobic biofilm reactor 7 is an upflow reactor, a...

Embodiment 2

[0040]The difference between this embodiment and Example 1 is that the main body of the anaerobic biofilm reactor 7 is composed of upper and lower sections of plexiglass tubes, the upper section of plexiglass tubes is used as the filler layer 71, and light fillers are housed inside, and the lower section of organic glass tubes is used as the packing layer 71, and the lower section of organic glass tubes The glass tube is used as the plant residue layer 72, and the plant residue is housed; the inner diameters of the two sections of plexiglass tubes are the same, and the tubes are separated by a screen 70;

[0041] For fixedly connecting two sections of plexiglass tubes, the anaerobic biofilm reactor 7 is also provided with a stainless steel ferrule 9, the stainless steel ferrule 9 includes an annular stainless steel ferrule 91 and a stainless steel bar 92, and the annular ferrule at the lower end of the stainless steel ferrule 9 The stainless steel sleeve 91 is stuck on the lowe...

Embodiment 3

[0043] This example illustrates the specific implementation of the method of the present invention.

[0044] Method of the present invention specifically comprises the steps:

[0045] (1) Denitrification reaction to remove nitrate: the pump pumps the water containing nitrate into the bottom of the upflow anaerobic biofilm reactor through the water inlet. The bottom of the upflow anaerobic biofilm reactor is filled with plant residues and the upper layer is filled There are light fillers attached to denitrifying microorganisms, and the light fillers and plant residues are separated by screens, and the nitrate-containing water flows from the bottom of the upflow anaerobic biofilm reactor through the screens to the upper layer through the screens, and the nitric acid in the water The salt is reduced to nitrogen by denitrification reaction;

[0046] Among them, the carbon source required for the reaction is provided by the plant residue, and the plant residue releases organic car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com