Dried orange peel tea product baking room wall body, preparation method of dried orange peel tea product drying room wall body and baking method of dried orange peel tea product

A technology of tea products and tangerine peel, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of unreported, etc., and achieve the effect of easy operation, better fragrance and quality, and simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

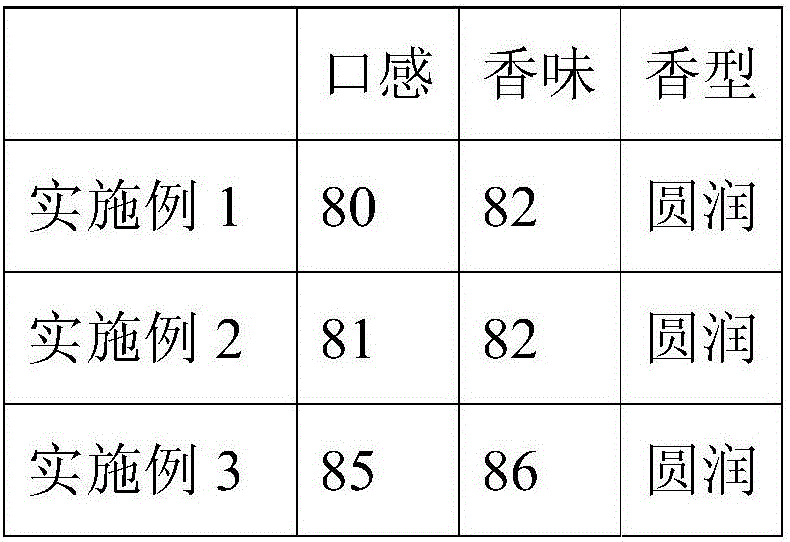

Embodiment 1

[0053] A wall of a drying room for tangerine peel tea products, the wall of a drying room for tangerine peel tea products includes the following components in parts by mass:

[0054] 50 parts of soil

[0055] Chenpi 1 part

[0056] 20 parts of water.

[0057] The soil is selected from brown soil.

[0058] The particle size of the orange peel is 8 mesh.

[0059] The preparation method of the wall of the drying room for dried tangerine peel tea products, the preparation method comprises the following steps:

[0060] (1) mix the soil of formula quantity, tangerine peel and water and / or tangerine peel water, obtain compound;

[0061] (2) The mixture is molded and dried to obtain the wall body of the drying room for the orange peel tea product.

[0062] The mixture described in step (1) is an agglomeration mixture;

[0063] The drying temperature in step (2) is 80°C.

Embodiment 2

[0065] A wall of a drying room for tangerine peel tea products, the wall of a drying room for tangerine peel tea products includes the following components in parts by mass:

[0066] Dirt 79 parts

[0067] Chenpi 30 parts

[0068] 49 parts of tangerine peel water.

[0069] The soil is selected from loess.

[0070] The particle size of the orange peel is 200 mesh.

[0071] The orange peel water is prepared by the following method: soak the orange peel in water, filter out the orange peel after 24 hours to obtain the orange peel water, wherein the mass ratio of the orange peel to water is 5:10.

[0072] The preparation method of the wall of the drying room for dried tangerine peel tea products, the preparation method comprises the following steps:

[0073] (1) mix the soil of formula quantity, tangerine peel and water and / or tangerine peel water, obtain compound;

[0074] (2) The mixture is molded and dried to obtain the wall body of the drying room for the orange peel tea ...

Embodiment 3

[0078] A wall of a drying room for tangerine peel tea products, the wall of a drying room for tangerine peel tea products includes the following components in parts by mass:

[0079] 55 parts of soil

[0080] Chenpi 5 parts

[0081] 25 parts of tangerine peel water.

[0082] The soil is selected from brown soil and loess with a mass ratio of 1:1.

[0083] The particle size of the orange peel is 100 mesh.

[0084] The tangerine peel is selected from tangerine peel powder.

[0085] The orange peel water is prepared by the following method: soak the orange peel in water, filter out the orange peel after 20 hours to obtain the orange peel water, wherein the mass ratio of the orange peel to water is 3:10.

[0086] The preparation method of the wall of the drying room for dried tangerine peel tea products, the preparation method comprises the following steps:

[0087] (1) mix the soil of formula quantity, tangerine peel and water and / or tangerine peel water, obtain compound;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com