Resin-based graphene heat conduction composite material and method for preparing same

A heat-conducting composite material and graphene technology, which is applied in the field of heat-conducting plastics, can solve the problems that graphene is difficult to effectively disperse and the thermal conductivity of heat-conducting plastics is not high, and achieve the effects of improving thermal conductivity, improving heat dissipation performance, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

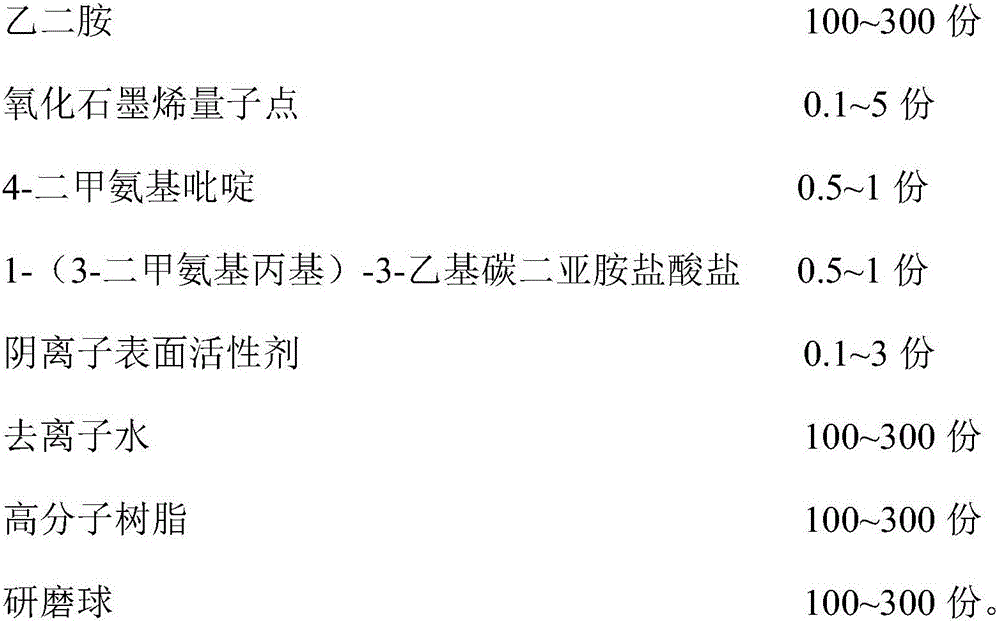

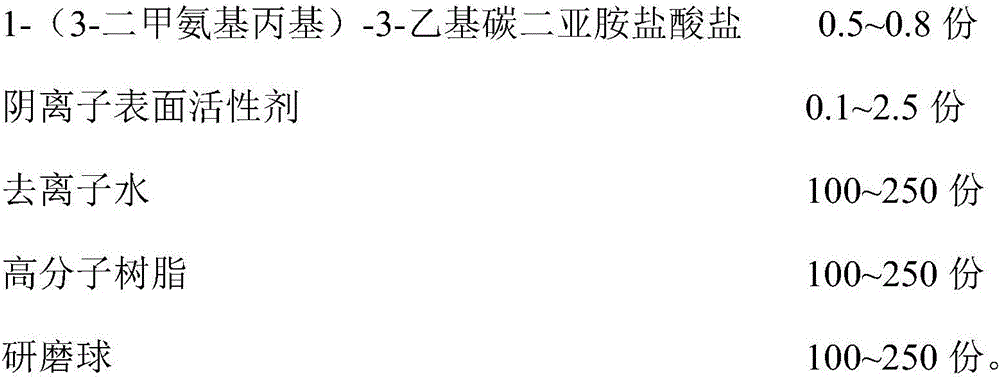

[0035] The preparation method of the resin-based graphene thermally conductive composite material provided by the embodiment of the present invention comprises the following preparation steps:

[0036] S1: Modification of graphene quantum dots

[0037]Add 0.1 to 5 parts of graphene oxide quantum dots, 0.5 to 1 part of 4-dimethylaminopyridine and 0.5 to 1 part of 1-(3-dimethylaminopropyl )-3-Ethylcarbodiimide hydrochloride, ultrasonically dispersed for 30 to 60 minutes, placed at 80 to 100°C for 12 to 48 hours, and the resulting mixture was cooled to room temperature, filtered, washed with water, and dried to obtain The first product; then put 1 to 5 parts of the first product and 0.1 to 3 parts of anionic surfactant in 100 to 300 parts of deionized water, ultrasonically disperse for 30 to 60 minutes, let stand for 12 to 24 hours, and then filter with suction Washing with water and drying to obtain the second product;

[0038] S2: Preparation of polymer resin nanopowder

[0...

Embodiment 1

[0046] The preparation method of resin-based graphene heat-conducting composite material comprises the following steps:

[0047] S1: Modification of graphene quantum dots

[0048] In 100g of ethylenediamine, add 0.1g of graphene oxide quantum dots, 0.5g of 4-dimethylaminopyridine and 0.5g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiethylene Amine hydrochloride, ultrasonically dispersed for 30 minutes, reacted at 80°C for 12h, cooled the reaction mixture to room temperature, filtered and washed with water, and dried at 60°C for 12h to obtain ethylenediamine grafted graphene oxide; 1g of ethylenediamine-grafted graphene oxide and 0.1g of sodium dodecylbenzenesulfonate were placed in 100g of deionized water, ultrasonically dispersed for 30min, after standing for 12h, filtered and washed with water, dried at 60°C for 12h, Obtain the graphene oxide modified by sodium dodecylbenzene sulfonate;

[0049] S2: Preparation of polymer resin nanopowder

[0050] Add 100g of polypropylene ...

Embodiment 2

[0055] The preparation method of resin-based graphene heat-conducting composite material comprises the following steps:

[0056] S1: Modification of graphene quantum dots

[0057] In 200g of ethylenediamine, 2.5g of graphene oxide quantum dots, 0.75g of 4-dimethylaminopyridine and 0.75g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiethylene were sequentially added Amine hydrochloride, ultrasonically dispersed for 45 minutes, reacted at 90°C for 30h, cooled the reaction mixture to room temperature, filtered and washed with water, and dried at 60°C for 18h to obtain ethylenediamine grafted graphene oxide; 3g of ethylenediamine-grafted graphene oxide and 2g of sodium dodecylbenzenesulfonate were placed in 200g of deionized water, ultrasonically dispersed for 45min, left to stand for 18h, filtered and washed with water, and dried at 60°C for 18h to obtain Graphene oxide modified by sodium dodecylbenzenesulfonate;

[0058] S2: Preparation of polymer resin nanopowder

[0059] Add 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com