PP material for infant car seat and injection molding process of PP material

A child seat and automobile technology, applied in the field of plastics, can solve the problems of high process cost and insufficient strength, and achieve the effects of strong operability, increased strength, and enhanced overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

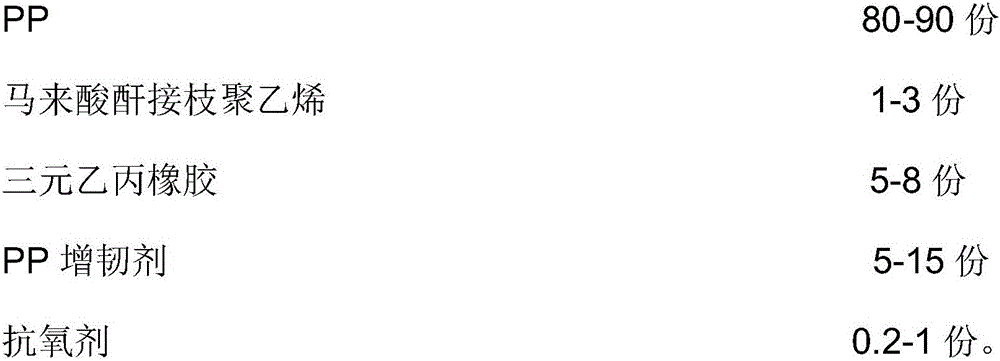

[0022] A PP material used for car child seats comprises the following components by weight.

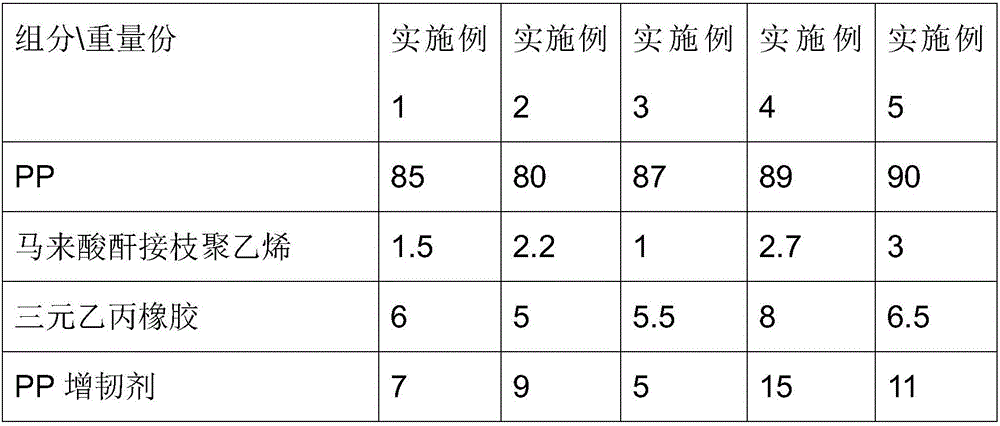

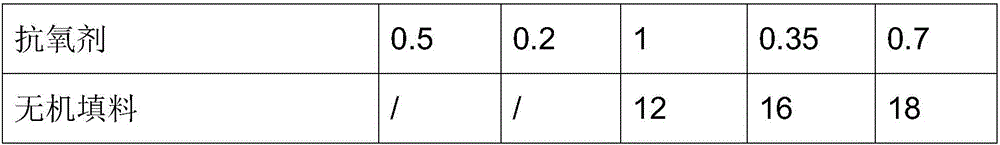

[0023] The PP material component (unit: parts by weight) described in the embodiment of table 1

[0024]

[0025]

[0026] Preferably, the PP toughening agent is ExxonMobil 6102PP toughening agent. ExxonMobil 6102PP toughening agent is a POE high-efficiency toughening agent produced by ExxonMobil Corporation. It has a significant toughening effect on PP materials and makes PP materials have better toughness performance at high and low temperatures.

[0027] Preferably, the antioxidant is a mixture of monophenylenedioctyl phosphite and antioxidant PNX 103. Phenyl diisooctyl phosphite is used as an antioxidant for polymers, which is excellent in reducing the yellowing of plastics. The antioxidant PNX 103 is a domestic high-efficiency antioxidant, and its stabilizing effect is several times higher than that of traditional 1010 antioxidants. The combined effect enhances the compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com