An online measuring device and method for the temperature of molten iron in a large blast furnace

A blast furnace molten iron and measuring device technology, applied in blast furnaces, inspection devices, blast furnace details, etc., can solve problems such as the difficulty in effectively and accurately detecting the temperature of molten iron at the blast furnace taphole, and difficulty in responding to the production status of the blast furnace, so as to avoid subjective factors impact, the effect of accurate and effective measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A kind of on-line measuring method of molten iron temperature of large-scale blast furnace of the present invention, the steps are as follows:

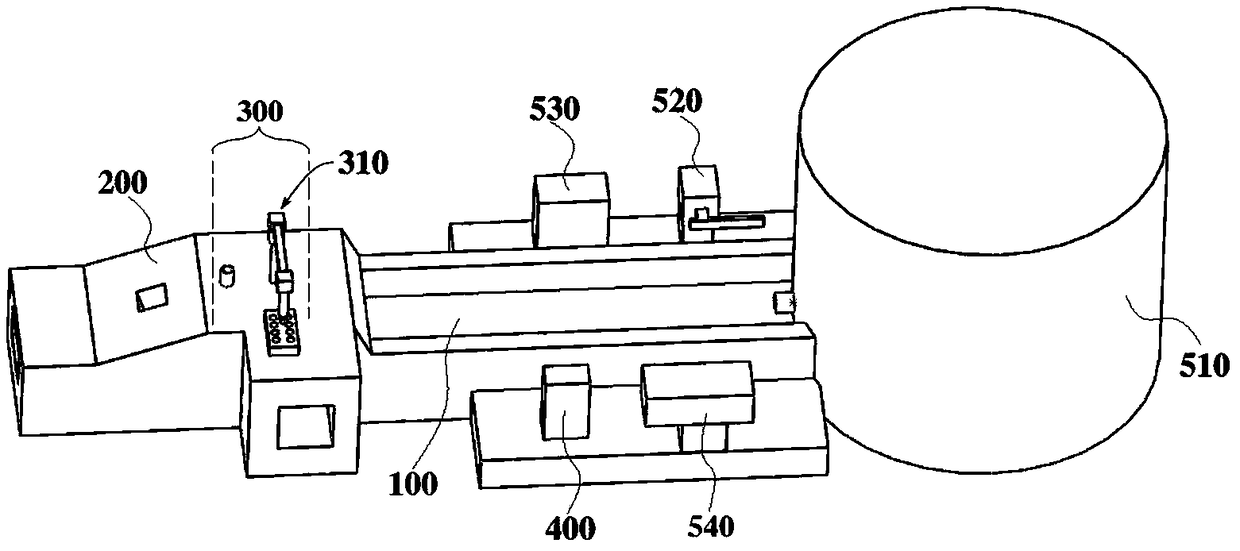

[0064] Step 1: Determine the tapping position, collect the position information of the mud cannon 520, the tapping machine 530 and the capping machine 540, and collect the accumulative time for the tapping machine 530 to continuously rotate and hit the tapping hole after the capping machine 540 removes the cover plate It is t1=10min, when t1=10≥5min, determine that the taphole corresponding to the uncapping machine 540 is the taphole for this tapping, and set the scheduled temperature measurement time as t mi , where t m1 = 60min, t m2 = 80min, t m3 =100min; that is, temperature measurement is performed when the effective tapping time reaches 60, 80 and 100min;

[0065] Step 2: Calculate the effective tapping time. After determining the tapping position, the tapping machine 530 returns to the original position, and then the ...

Embodiment 2

[0070] A kind of on-line measuring method of molten iron temperature of large-scale blast furnace of the present invention, the steps are as follows:

[0071] Step 1: Determine the tapping position, collect the position information of the mud cannon 520, the tapping machine 530 and the capping machine 540, and collect the accumulative time for the tapping machine 530 to continuously rotate and hit the tapping hole after the capping machine 540 removes the cover plate It is t1=10min, when t1=10min≥5min, determine that the taphole corresponding to the uncapping machine 540 is the taphole for this tapping, and set the scheduled temperature measurement time as t mi , where t m1 = 60min, t m2 = 80min, t m3 = 100min; that is, temperature measurement is performed when the effective tapping time reaches 60min, 80min and 100min;

[0072] Step 2: Calculate the effective tapping time. After determining the tapping position, the tapping machine 530 returns to the original position, and...

Embodiment 3

[0078] A kind of on-line measuring method of molten iron temperature of large-scale blast furnace of the present invention, the steps are as follows:

[0079] Step 1: Determine the tapping position, collect the position information of the mud cannon 520, the tapping machine 530 and the capping machine 540, and collect the accumulative time for the tapping machine 530 to continuously rotate and hit the tapping hole after the capping machine 540 removes the cover plate For t1=8min, when t1=10min≥5min, determine that the taphole corresponding to the uncapping machine 540 is the taphole for this tapping, and set the scheduled temperature measurement time as t mi , where t m1 = 60min; that is, the temperature is measured when the effective tapping time reaches 60min;

[0080] Step 2: Calculate the effective tapping time. After determining the tapping position, the tapping machine 530 returns to the original position, and then the uncapping machine 540 covers the tapping channel 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com