Device for assisting green ball in disengaging and ball press machine

A technology of ball briquetting machine and green ball, which is applied in the field of auxiliary ball dropping device and ball briquetting machine, can solve problems such as the quality of dropped raw balls, and achieve the effects of improving the ball forming rate, solving the low quality of raw balls, and improving the quality of raw balls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

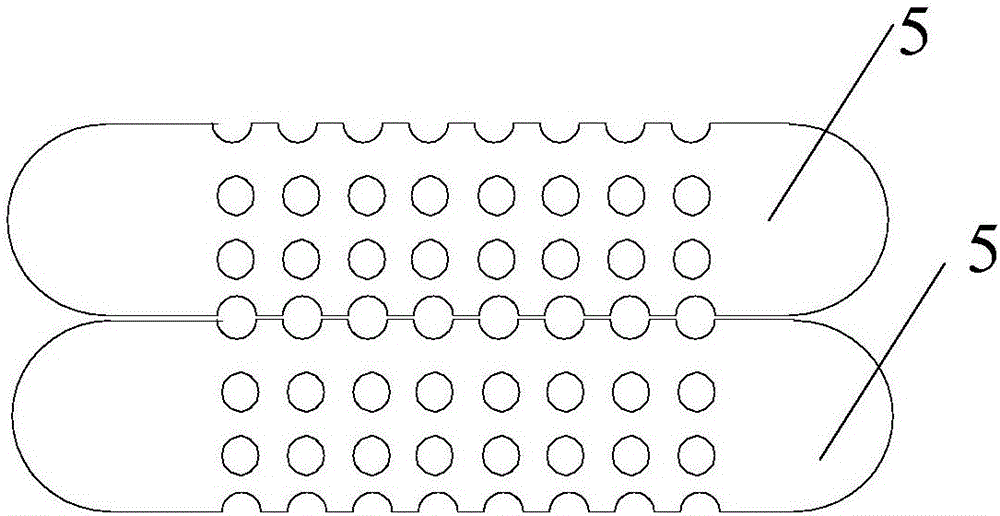

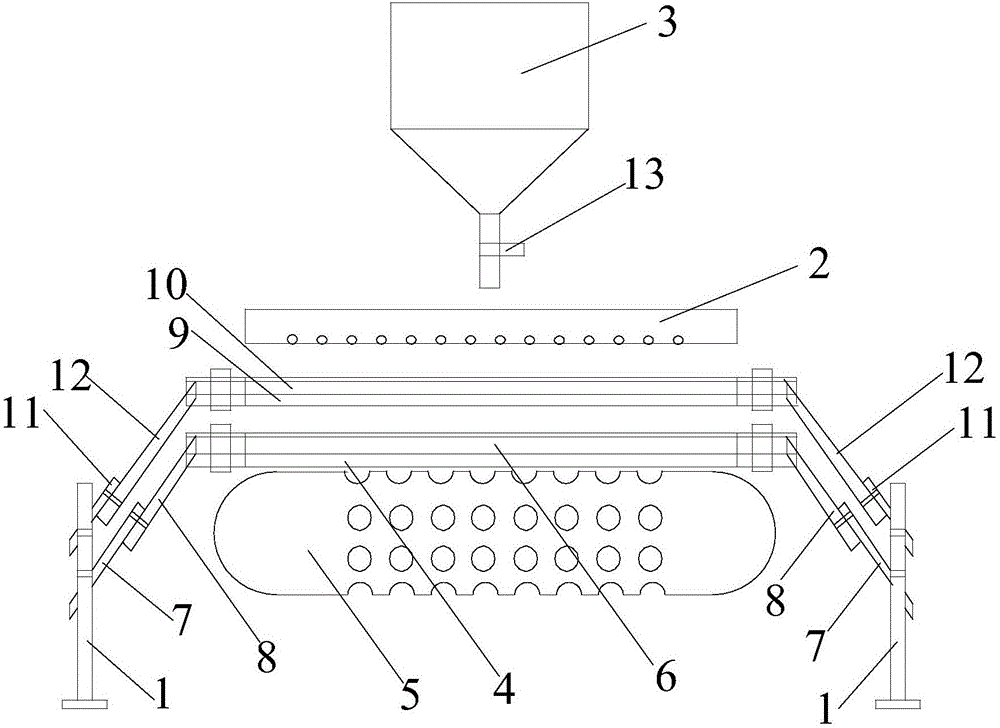

[0027] In one embodiment, the first brush holder is composed of a first clamping piece 6, a first fixed arm 7 and a first telescopic arm 8, so that only one end of the first clamping piece 6 is connected to the fixed frame 1 superior.

[0028] In another embodiment, such as figure 2 As shown, in order to fix the first clamping part 6 more stably, the first brush holder is composed of the first clamping part 6 , two first fixed arms 7 and two first telescopic arms 8 . Then one end of a first fixed arm 7 is respectively fixed at both ends of the first clamping member 6, and the other end of each first fixed arm 7 is respectively connected with one end of a first telescopic arm 8, and each first telescopic arm The other end of the arm 8 is fixed on the fixed frame 1 .

[0029] Specifically, the first telescopic arm 8 is an electric arm, which realizes automatic lifting of the first clamping member 6 .

[0030] Further, the aid ball shedding device provided by the embodiment o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap