Corrosion resistant and anti-nodulation sink roller

An anti-nodulation and sinking roll technology, applied in coating, metal material coating process, hot-dip plating process, etc., can solve problems such as waste of resources, affecting product quality, poor flow, etc., and achieve strong resistance to high aluminum and zinc Liquid corrosion ability, solve the problem of nodulation, and improve the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

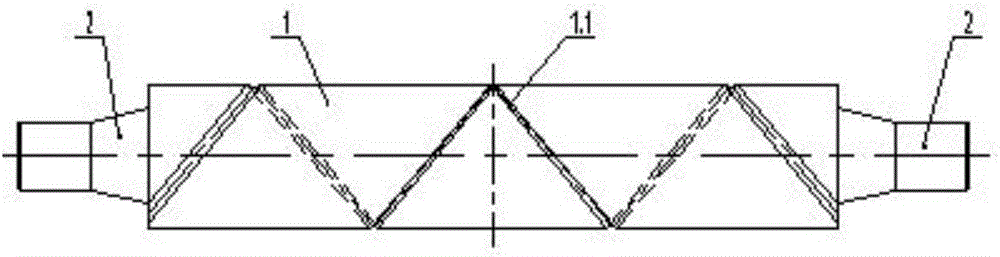

[0014] The anti-corrosion and anti-nodulation sinking roller shown in the accompanying drawings includes a cylindrical roller body 1 and a roller shaft 2; the axially symmetrical center line of the roller body 1 is used as the dividing line, and opposite sides of the dividing line are provided on the surfaces of the roller body 1. The spiral groove 1.1 in the direction of rotation; the bottom of the spiral groove 1.1 is arc-shaped, and the spiral groove 1.1 becomes wider and wider from the dividing line to both sides.

[0015] The surface of the roller body is provided with a corrosion-resistant layer. In this embodiment, the surface of the roller body 1 is sprayed with a layer of ternary boride ceramic composite powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com