Automobile mould repair process with excellent repair effect

A technology of automobile molds and molds, which is applied in the direction of metal material coating process, superimposed layer plating, coating, etc., can solve the problems of insufficient competitiveness of domestic automobile molds, product quality decline, large mold deformation, etc., to avoid Decrease in product quality, prolong service life, and ensure the effect of using accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

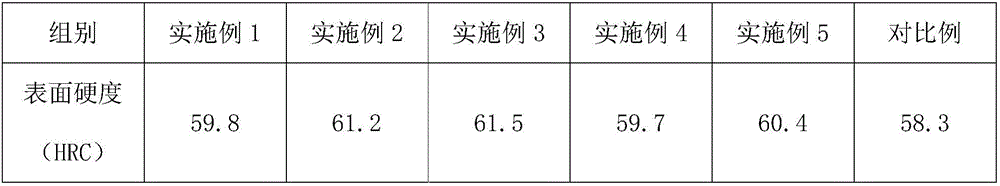

Examples

Embodiment 1

[0026] A repair process for automobile molds with excellent repair effect, the steps are as follows:

[0027] 1) Cleaning the surface of the mold, specifically, cleaning the mold with methacron solvent at 70°C;

[0028] 2) Use the worn area of the mold as the repair area, and polish the repair area. Specifically, firstly use 400-mesh dry sandpaper to polish the mold for the first time, and after grinding evenly, use 800-mesh dry sandpaper to polish the mold again to make the mold evenly Finally, put the mold in water, and use 1200-mesh water-grinding sandpaper for final grinding. After grinding evenly, dry the mold at 110°C;

[0029] 3) Perform initial tempering treatment on the mold, first raise the temperature to 500°C, temper for 2 hours, then cool down to 210°C, temper for 1 hour, and finally cool naturally;

[0030] 4) Laser cladding is used to clad the repaired alloy powder on the repaired area to form a repaired layer, and the surface of the repaired layer is 0.3mm l...

Embodiment 2

[0036] A repair process for automobile molds with excellent repair effect, the steps are as follows:

[0037] 1) Cleaning the surface of the mold, specifically, cleaning the mold with methacron solvent at 70°C;

[0038] 2) Use the worn area of the mold as the repair area, and polish the repair area. Specifically, firstly use 400-mesh dry sandpaper to polish the mold for the first time, and after grinding evenly, use 800-mesh dry sandpaper to polish the mold again to make the mold evenly Finally, put the mold in water, and use 1200-mesh water-grinding sandpaper for final grinding. After grinding evenly, dry the mold at 115°C;

[0039] 3) Perform initial tempering treatment on the mold, first raise the temperature to 510°C, temper for 2.5 hours, then cool down to 220°C, temper for 1 hour, and finally cool naturally;

[0040] 4) Laser cladding is used to clad the repair alloy powder on the repair area to form a repair layer, and the surface of the repair layer is 0.35mm lower ...

Embodiment 3

[0046] A repair process for automobile molds with excellent repair effect, the steps are as follows:

[0047] 1) Cleaning the surface of the mold, specifically, cleaning the mold with methacron solvent at 70°C;

[0048] 2) Use the worn area of the mold as the repair area, and polish the repair area. Specifically, firstly use 400-mesh dry sandpaper to polish the mold for the first time, and after grinding evenly, use 800-mesh dry sandpaper to polish the mold again to make the mold evenly Finally, put the mold in water, and use 1200-mesh water-grinding sandpaper for final grinding. After grinding evenly, dry the mold at 115°C;

[0049] 3) Perform initial tempering treatment on the mold, first raise the temperature to 515°C, temper for 2.5 hours, then cool down to 225°C, temper for 1 hour, and finally cool naturally;

[0050] 4) Laser cladding is used to clad the repaired alloy powder on the repaired area to form a repaired layer, and the surface of the repaired layer is 0.4mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com