Pre-oxidation furnace hot air circulation system

A technology of circulation system and pre-oxidation furnace, which is applied to the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems affecting the uniformity of the air inlet channel temperature, reduce the efficiency of hot air circulation, and the quality of pre-oxidation materials, etc., to achieve heat The loss and air volume loss are small, the volume is reduced, and the effect of reducing wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

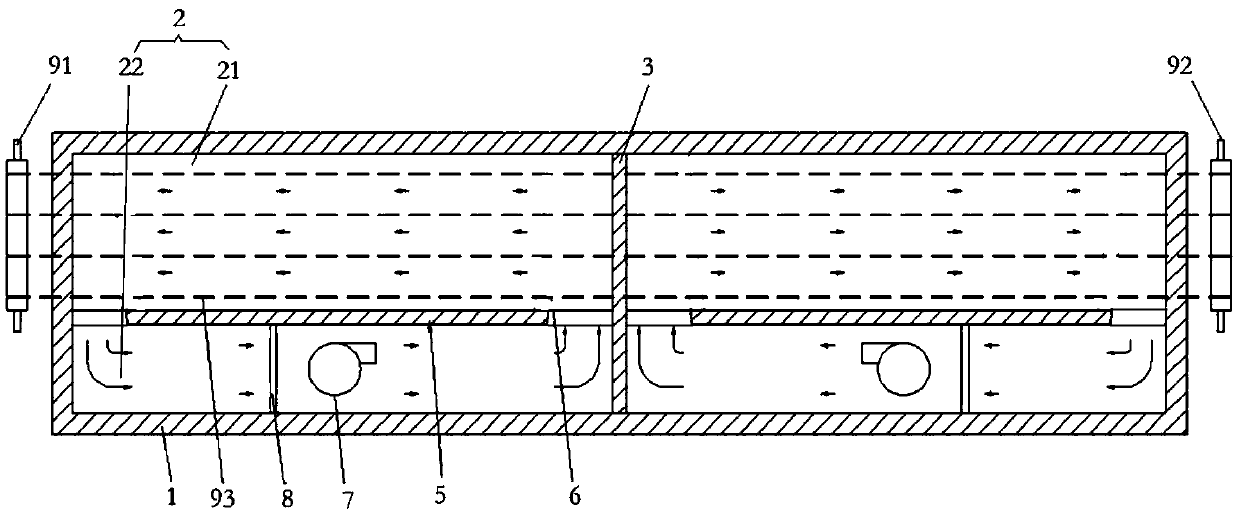

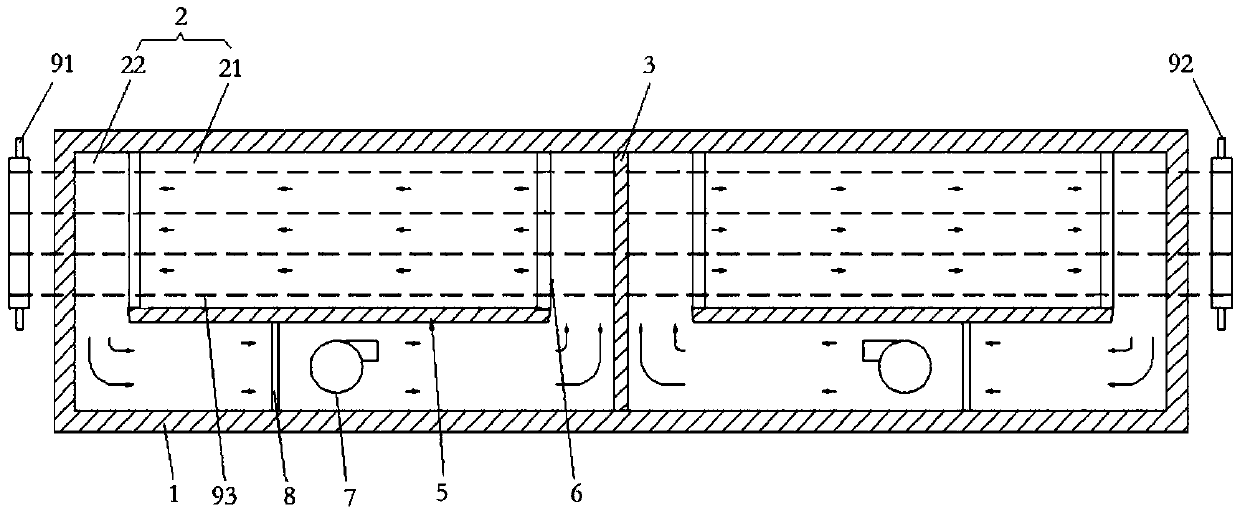

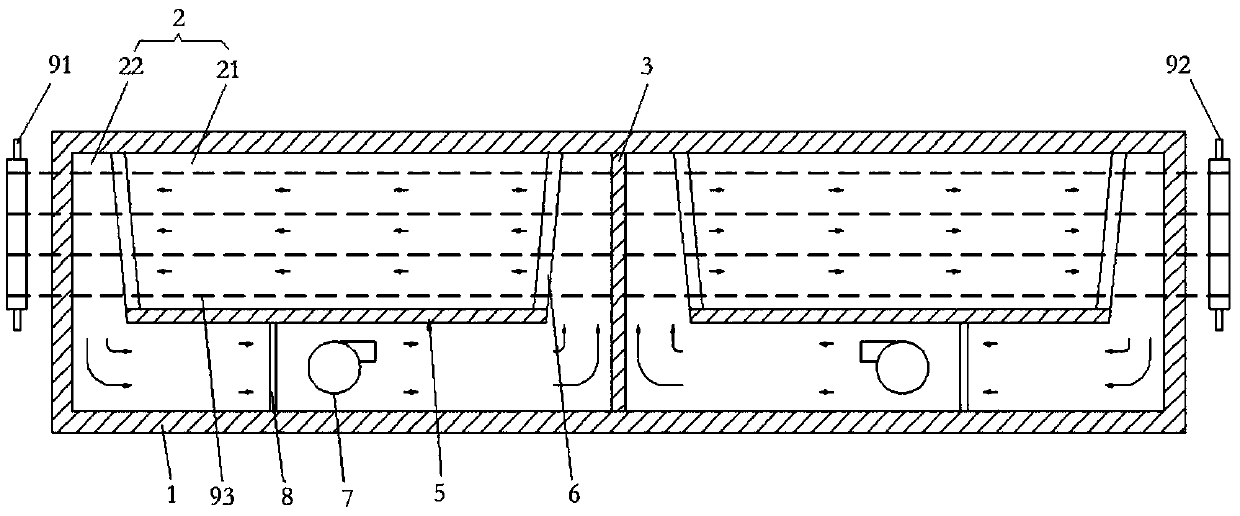

[0028] Such as Figure 1~4 As shown, the present invention provides a hot blast circulation system for a pre-oxidation furnace, which system includes a furnace body 1, a hot blast circulation channel 2 arranged in the furnace body 1; the hot blast circulation channel 2 includes an air inlet channel 21 and a Return air channel 22; the body of furnace 1 is provided with at least one partition wall 3 arranged along the cross-sectional direction inside the body of furnace, and the partition wall 3 divides the interior of the body of furnace 1 into at least two parts in the length direction. An independent hot air circulation unit; each of the hot air circulation units is provided with a longitudinal partition 5 along the length direction of the furnace body, and the top and bottom of the longitudinal partition 5 are respectively connected with the inner wall of the furnace body 1 The two ends of the longitudinal partition 5 are connected with the inner wall of the furnace through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com