Self-moving type vehicular bridge for striding over belt conveyors

A belt conveyor, self-moving technology, used in pedestrian bridges, bridges, bridge parts, etc., can solve the problems of poor mobility of rigid road bridges, inability to change the installation position, cumbersome anchor bolt fixing, etc. The effect of reducing the space occupied and the trouble of assembling and disassembling the auxiliary bridge body, and improving the work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

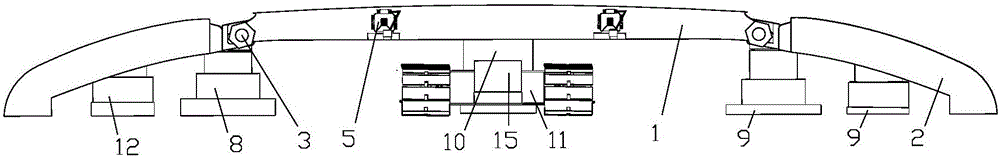

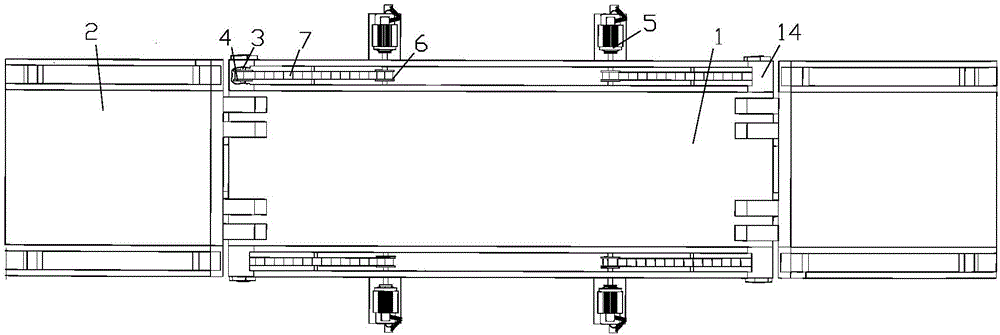

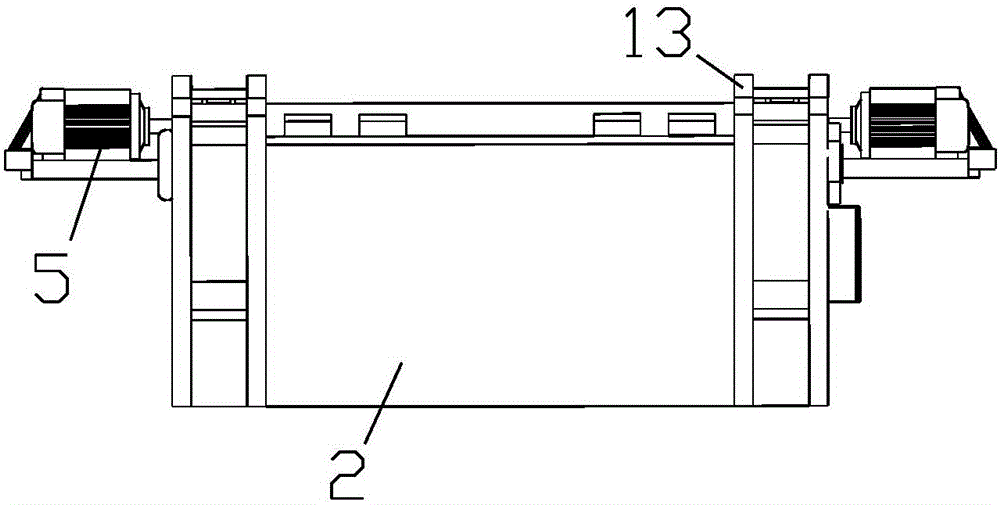

[0021] Such as Figure 1 to Figure 4 As shown, a self-moving driving bridge for crossing belt conveyors belongs to the transportation auxiliary equipment for open-pit mining. The transportation route of the vehicle.

[0022] The self-moving driving bridge used for cross-belt conveyor of the present invention includes a main bridge body 1 and two auxiliary bridge bodies 2, one end of the auxiliary bridge body 2 is fixed with a transmission shaft 3, and both ends of the transmission shaft 3 are provided with first chains. Wheel 4, the two opposite ends of the main bridge body 1 in the length direction are respectively hinged with the two auxiliary bridge bodies 2 through the transmission shaft 3 to form an arc-shaped bridge deck, and the transmission shaft 3 can rotate relative to the main bridge body 1. The upper surface of the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com