A steel pipe pile with hinged enlarged head

A technology of steel pipe pile and enlarged head, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of easy infiltration of soil particles, increase construction cost, limited uplift and compression bearing capacity, etc., and achieve the expansion effect. range, increasing shear strength, increasing the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

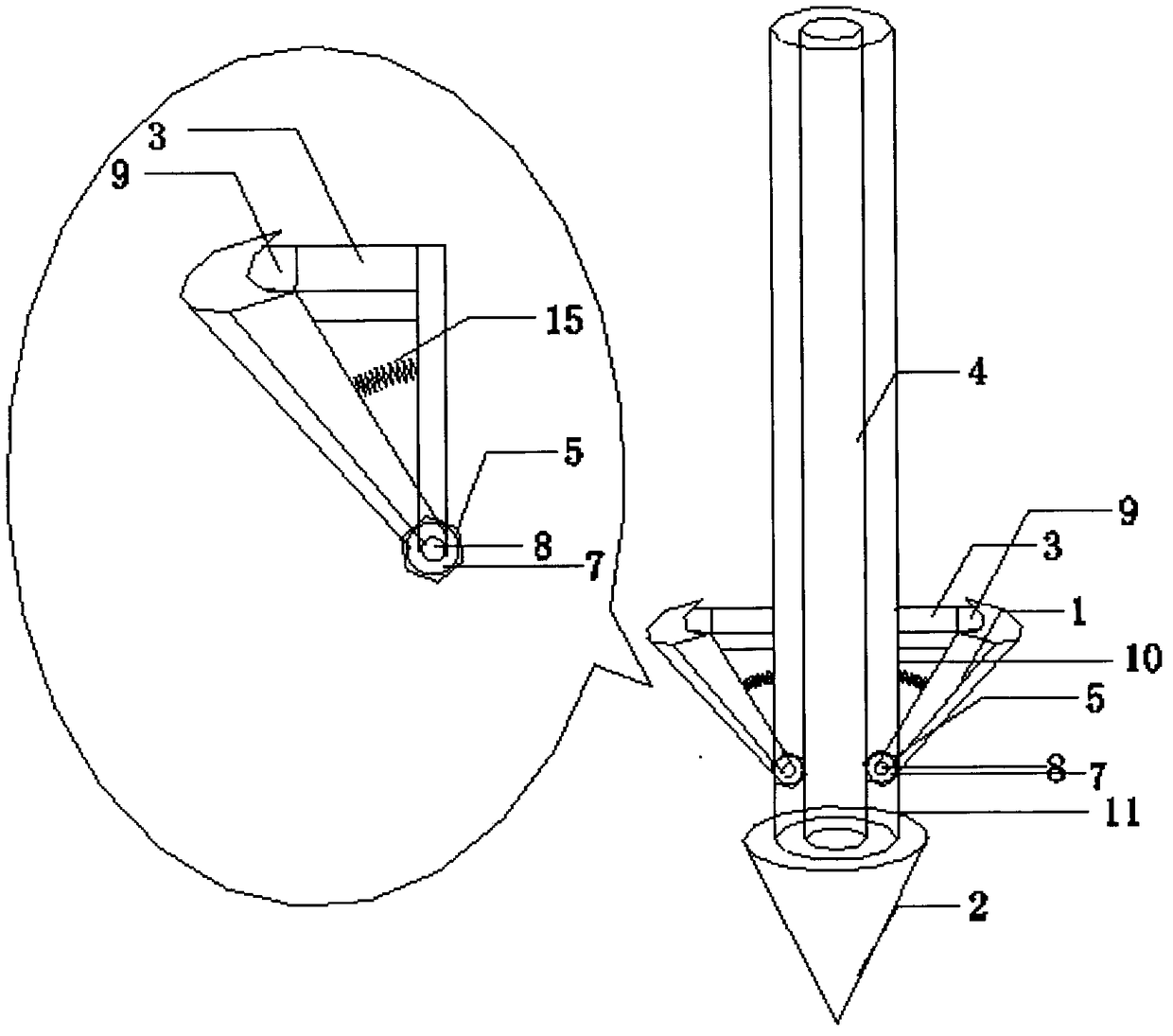

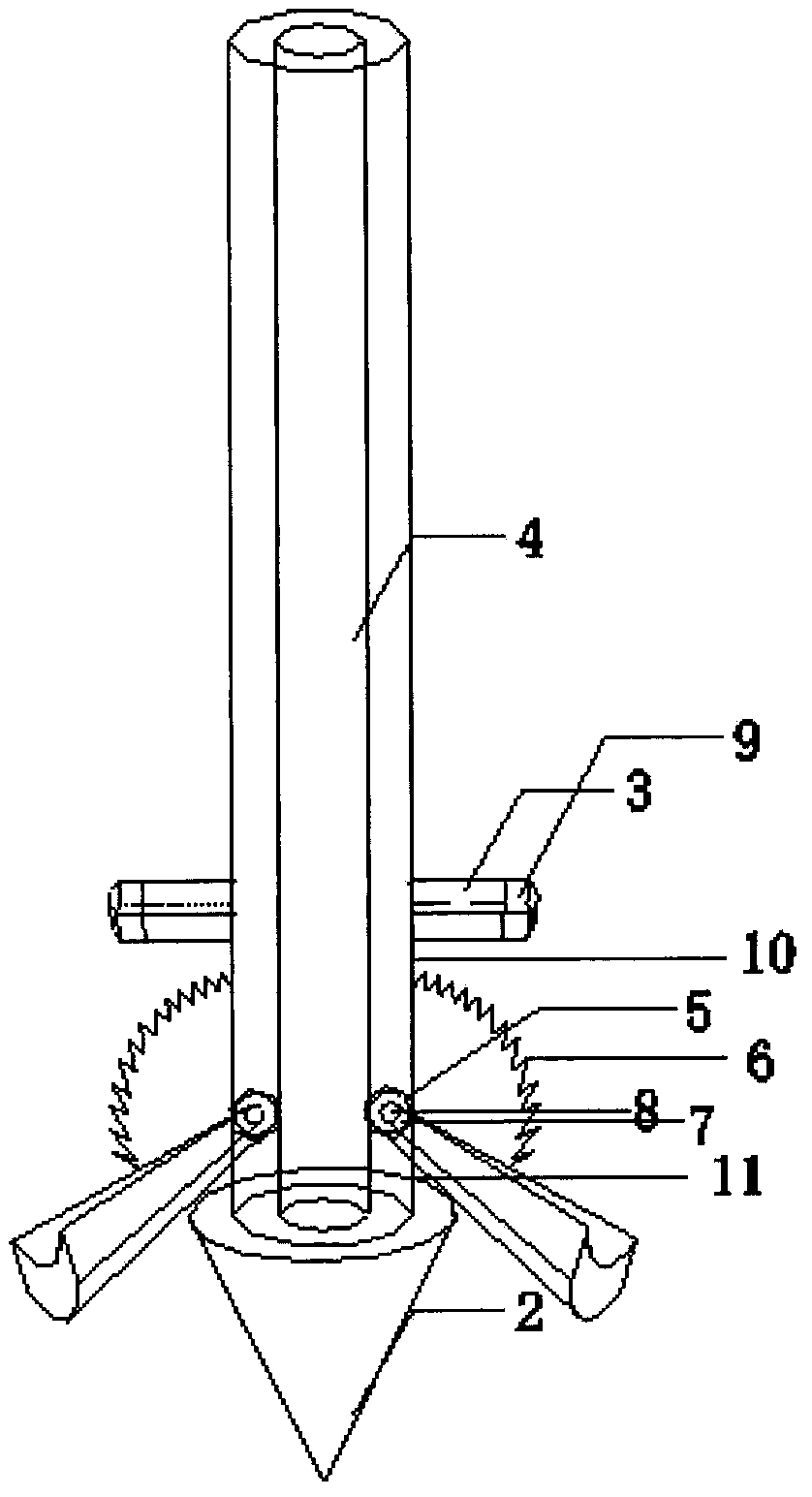

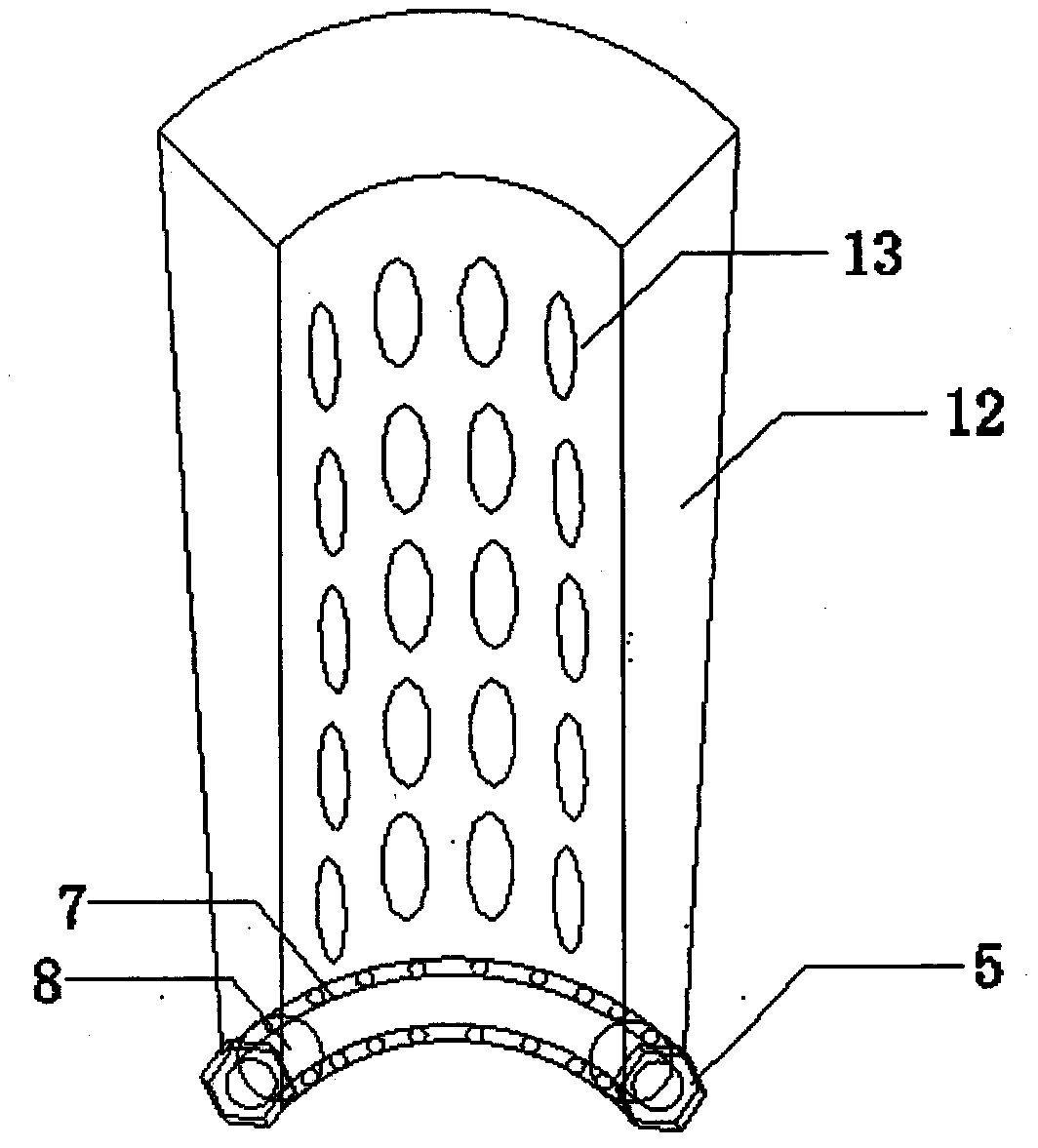

[0023] see Figure 1-4 As shown, a steel pipe pile with a hinged enlarged head includes a variable thickness hollow steel sheet 1, a ball bearing 7 is welded at the end of the steel pipe pile, a rotating shaft 8 is nested in the ball bearing 7, and the rotating shaft 8 is connected to the variable thickness hollow steel sheet. The steel sheet 1 is fixed by two symmetrical bolts 5 . Spray ports 10 and 11 are respectively arranged on the upper and lower sides of the rotating shaft, and a magnet fixing device 3 is welded above the position of the spraying port 10 on the upper part of the rotating shaft, and the magnet block 9 is fixed on the magnet fixing device, and a spring is connected to the rotating shaft and the pile body 6. The ball bearing 7 is 1 / 4 arc-shaped, symmetrically welded to the end of the pile body, and bolt holes are symmetrically arranged at both ends.

[0024] Bolt holes are symmetrically arranged at the ends of the variable-thickness hollow steel sheet 1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com