Method for pouring different grades of concrete to beam column junctions

A technology of beam-column joints and concrete, which is applied in the direction of construction, building structure, and building material processing, can solve problems such as poor concrete construction quality, and achieve low construction technical difficulty, labor saving, and strong operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further illustrated below by specific examples.

[0017] In a certain housing construction project, the concrete label of the column is C45, and the concrete label of the beam and slab is C35. The concrete pouring operation is carried out by the method mentioned above, and the pouring quality is very good.

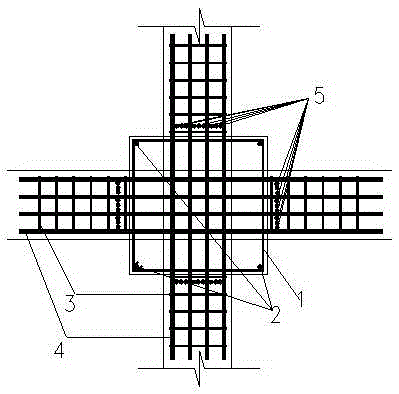

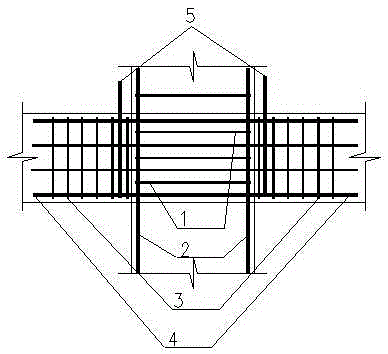

[0018] Such as figure 1 , figure 2 as shown,

[0019] The implementation steps of the construction method are as follows:

[0020] The first step is to bind the column reinforcement (column stirrup 1, column main reinforcement 2) until it is 1m higher than the upper surface of the upper floor;

[0021] The second step is to set up the column formwork and support system to the bottom of the upper beam;

[0022] The third step is to set up the steel pipe support system and formwork for the scaffolding of the upper beam and slab, and bind the beam reinforcement (beam stirrup 3, beam main reinforcement 4);

[0023] The fourth step is to in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com