Shied cutter head abrasion repairing construction method in tunnel

A wear repair and shield cutter head technology, applied in tunnels, earth-moving drilling, mining equipment, etc., can solve the problems of heavy cutter seat, wear of cutter head outer edge, inconvenient replacement, etc., to shorten the construction period and increase stability. The effect of stability and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

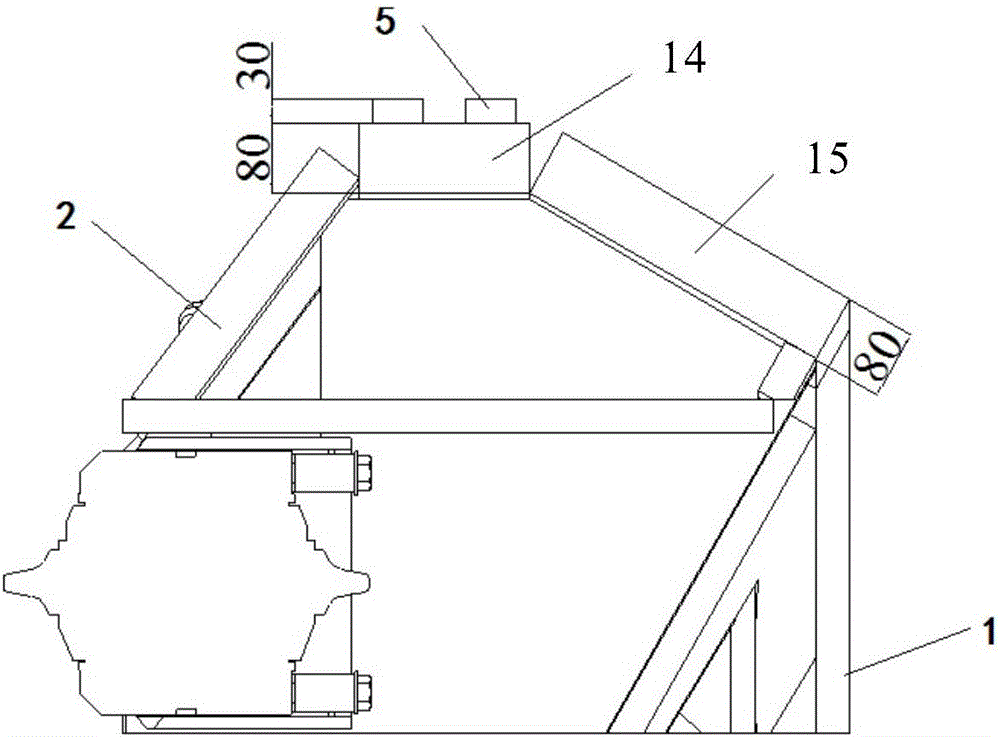

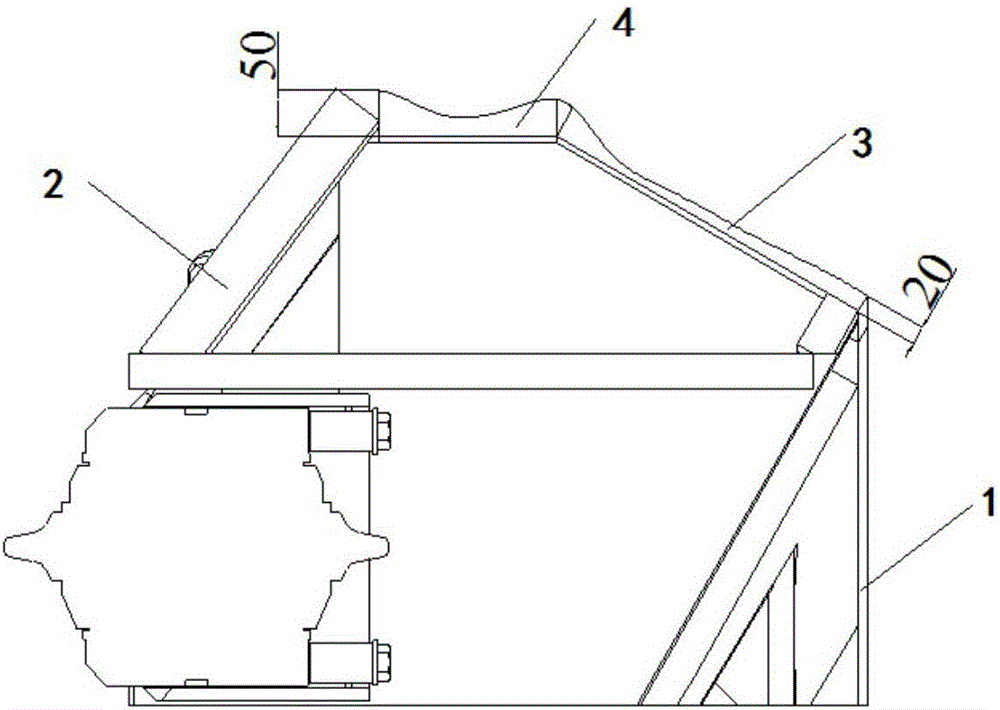

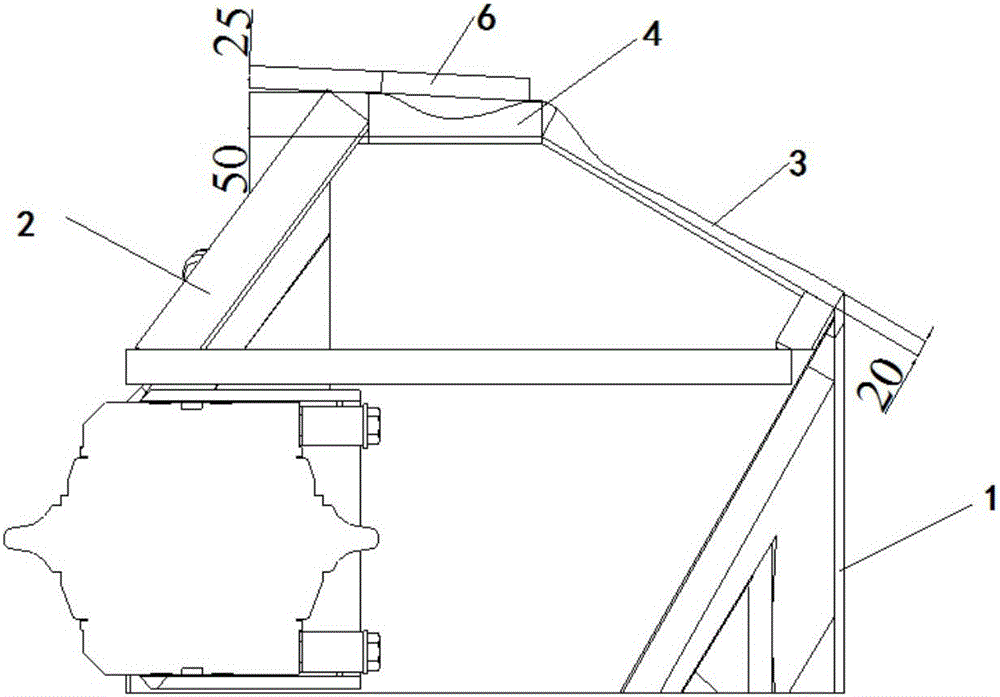

[0048] Such as Figure 1 to Figure 13 As shown, the wear repair construction method in the shield cutterhead tunnel of the present invention comprises the following steps:

[0049] Step 1. Excavate the cutter head in the tunnel to repair the working space: the shield machine is excavated until the full-section hard rock stops running, and the working space is repaired by manually digging the cutter head by taking advantage of the stability of the tunnel face at the position of the full-section hard rock;

[0050] The working space for repairing the cutterhead is a three-dimensional space with a depth of 1m in the direction of the twelve o'clock of the cutterhead and 0.5m from the top of the shield shell 1;

[0051] In actual construction, the shield machine enters the full-section hard rock, and utilizes the stability of the face of the full-section hard rock to repair the wear of the cutter head in the tunnel, avoiding the need to open a well on the ground and repair the wear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com