Anti-loosening bolt

A technology for preventing loosening of bolts and screws, applied in the directions of bolts, screws, nuts, etc., can solve the problems of crashing into the ground, crash, screw falling off affecting the normal operation of the equipment, etc., to improve stability, safety, and strong selectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

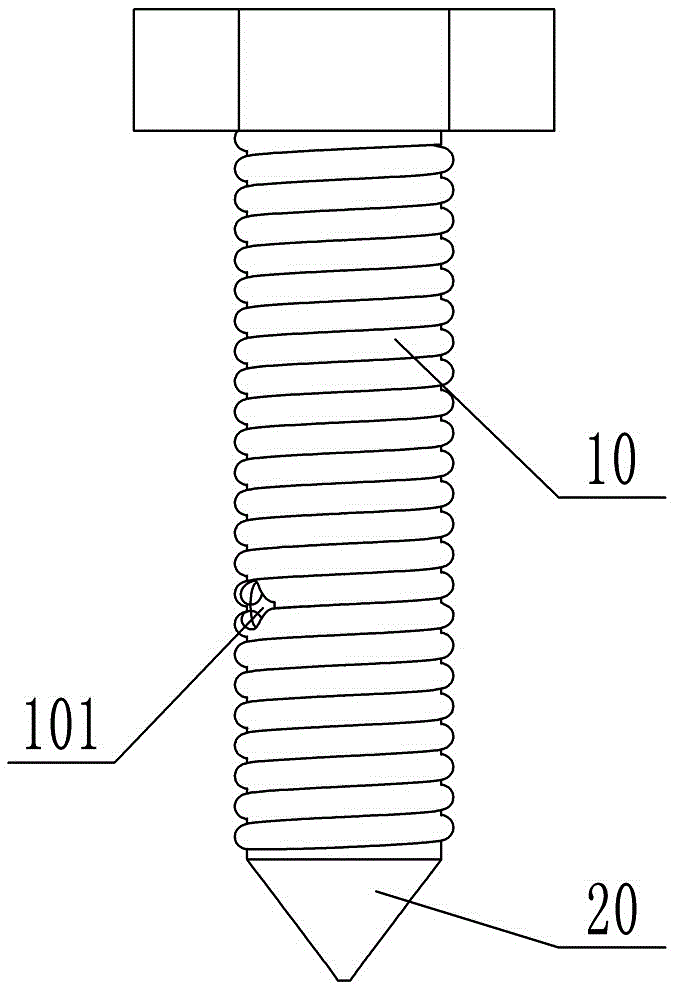

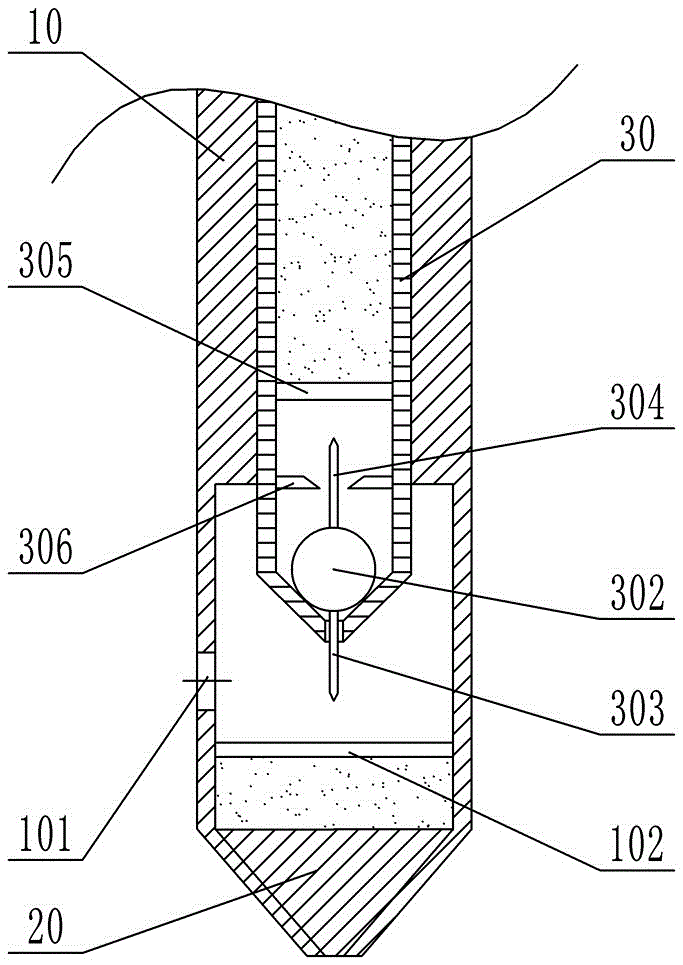

[0016] The reference signs in the drawings of the description include: screw 10, glue discharge port 101, first plastic film 102, cone head 20, locking rod 30, sealing ball 302, first needle 303, second needle 304, second plastic Membrane 305 , baffle 306 .

[0017] Such as figure 1 , figure 2 As shown, a lock bolt mainly includes three parts: a screw rod 10 , a nut connected to the screw rod 10 and a locking rod 30 . The lower end of the screw rod 10 is provided with a conical head 20, so that the screw rod 10 has the function of a screw, and the operation is more convenient. A first cavity is provided in the screw 10, and a first plastic film 102 is arranged in the first cavity. The first plastic film 102 divides the first cavity into upper and lower parts, the lower part is the first raw material cavity, and the upper part It is a mixing chamber, and glue A is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com