vehicle clutch

A clutch and clutch ring technology, applied in the direction of clutch, friction clutch, mechanical drive clutch, etc., can solve the problem of increasing the volume of the clutch, and achieve the effect of reducing the size, reducing the working force, reducing the size and capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Hereinafter, although preferred embodiments of the present invention will be described in detail with reference to the drawings, the present invention is not limited or limited to these embodiments. For reference, the same reference numerals denote substantially the same elements in this specification, and the contents described in other drawings can be cited and described according to this rule, and the contents that are obvious or redundant to those skilled in the art can be omitted.

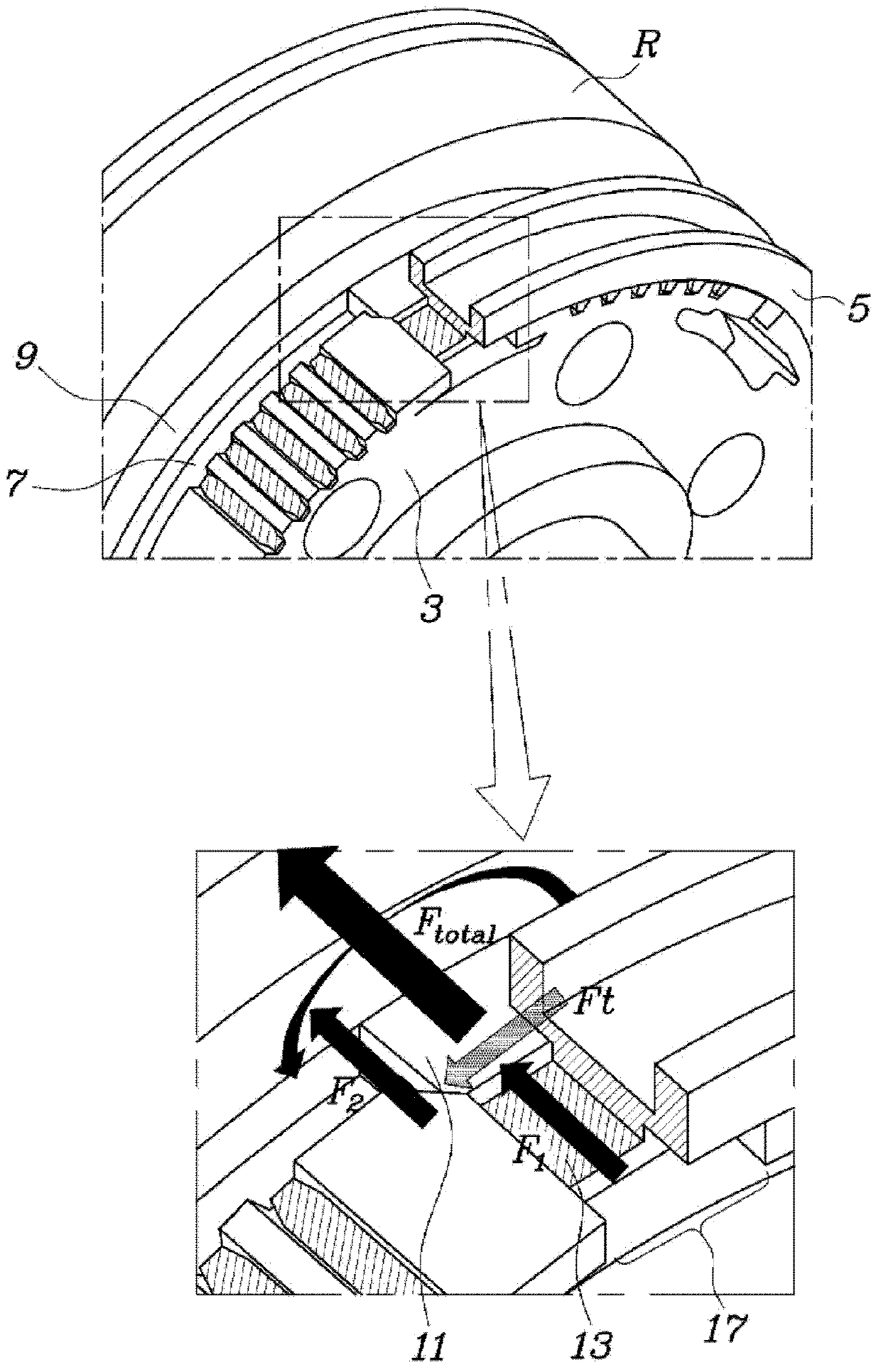

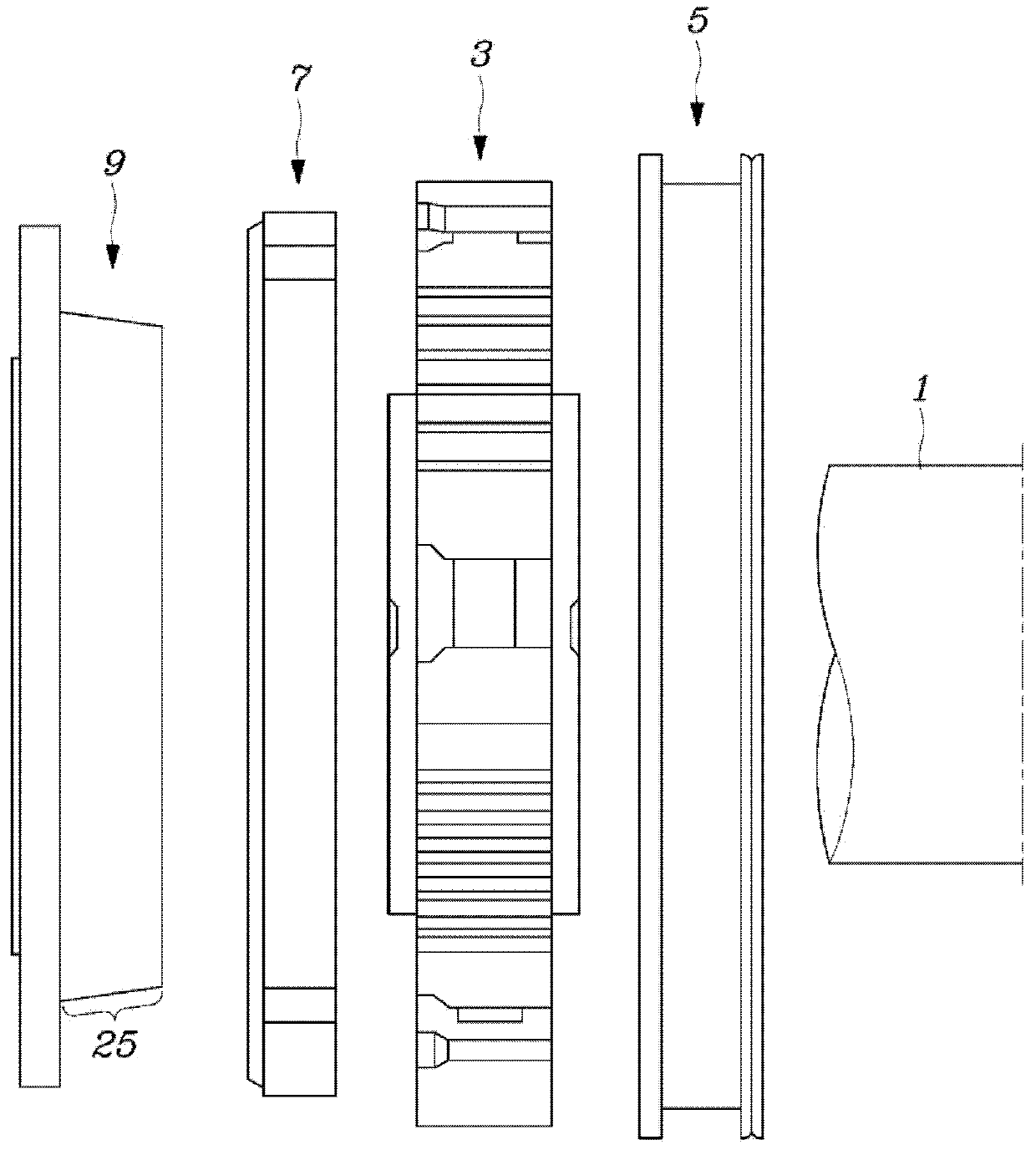

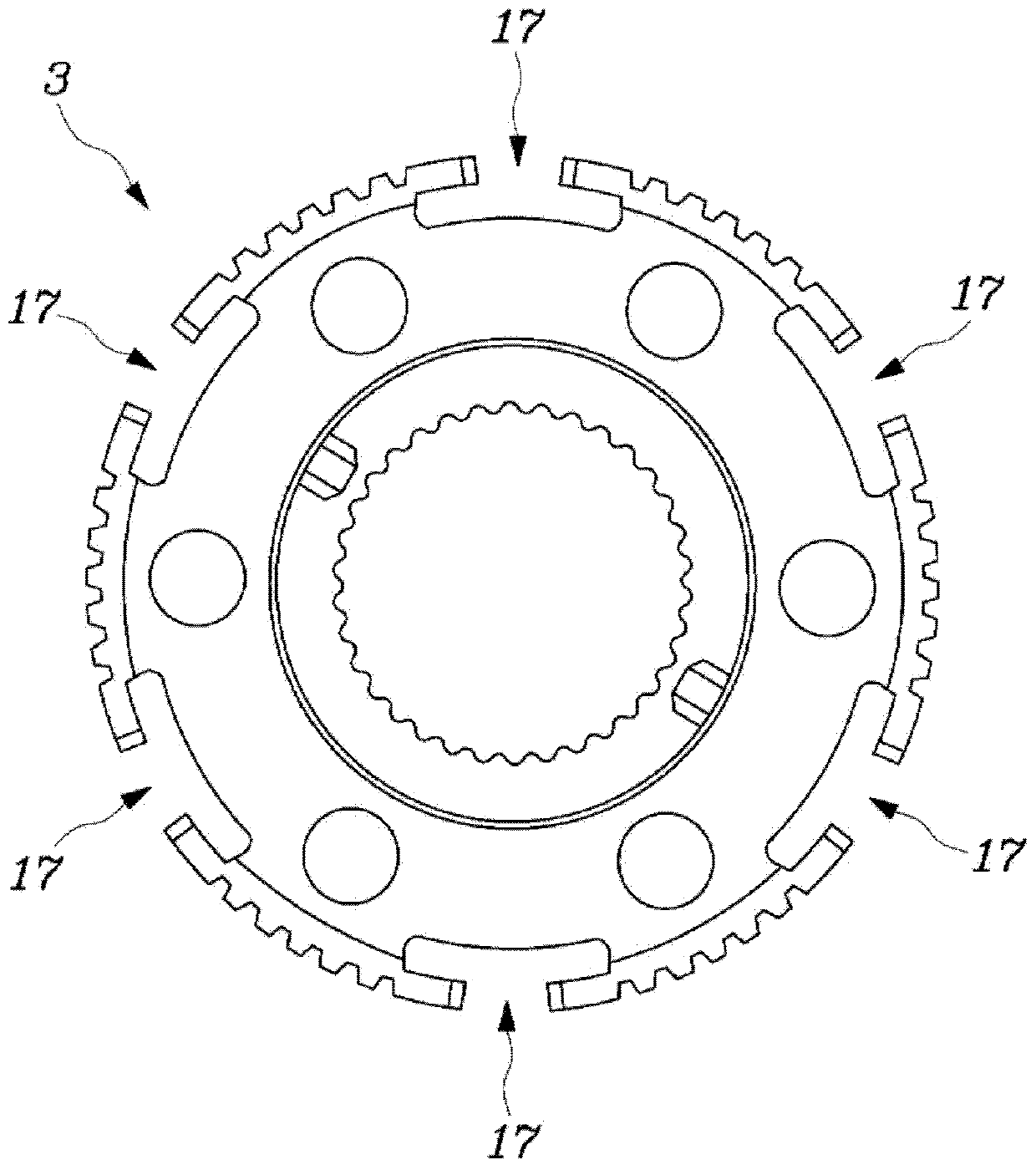

[0054] refer to Figure 1 to Figure 8 , the vehicle clutch of the embodiment of the present invention includes: a disc hub (hub) 3, which is arranged on the rotating shaft 1 in a state where the rotation is limited; The longitudinal direction of the above-mentioned rotating shaft (hereinafter referred to as the axial direction) can be provided in a manner of linear sliding; the clutch member 9 is provided in a state capable of relative rotation with respect to the above-mentioned rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com