Polymer oil pipeline joint with static electricity guiding removal realized through conduction in direction of pins of spigot end face

A polymer pipe and oil pipeline technology, applied in the direction of pipes/pipe joints/fittings, through components, mechanical equipment, etc., can solve the problems of decreased reliability of electrostatic connection, increased cost, deposition of impurities, etc., and achieves strong field engineering adaptability, Ensure connection reliability and uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

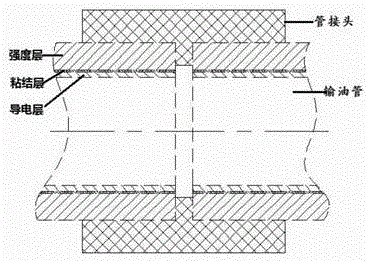

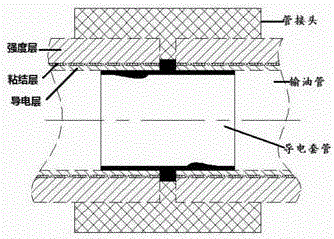

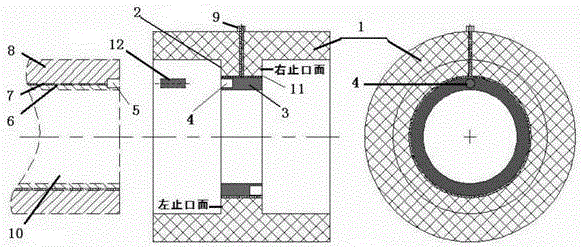

[0032] A polymer oil delivery pipe joint that conducts static electricity through the axial conduction of the pin on the end face of the spigot, which includes a polymer pipe body 1, and the inside of the polymer pipe body 1 is provided with an inwardly convex ring body 2, the ring body The two end surfaces of 2 are respectively used as the mouth surface and the end of the polymer oil pipeline to be connected, and a conductive ring 3 is bonded to the inner surface of the ring body 2, and the two end surfaces of the conductive ring 3 and the ring The left and right spigot surfaces on both sides of the body 2 are flush, the inner diameter of the conductive ring 3 is consistent with the inner diameter of the polymer oil pipeline, and the thickness of the conductive ring 3 is not less than the thickness of the conductive layer of the polymer oil pipeline. There are a number of first pin holes 4 for inserting the pin shaft 12, and a second pin hole 5 matching the size of the pin 12 ...

Embodiment 2

[0044] The difference between this embodiment and Embodiment 1 is that the depth of the pin hole 4 is 1 / 3 of the wall thickness of the oil delivery pipe 10 to be connected. The number of the pin hole 4 is 2, which are evenly distributed on the end surface of the conductive ring 3, that is, the positions on the circumference of the conductive ring 3 differ by 180 degrees, and the positions on the circumference of the left and right end surfaces of the conductive ring 3 differ by 90 degrees, such as Figure 7 shown.

Embodiment 3

[0046] The difference between this embodiment and Embodiment 1 is that the polymer oil delivery pipe joint is a right-angle elbow joint. The pin and the conductive ring are integrally formed at one time. The thickness of the conductive ring 3 is three times the thickness of the conductive layer 6 of the oil pipeline to be connected. The depth of the pin hole 4 is 1 / 4 of the wall thickness of the oil pipeline to be connected. The number of the pin holes 4 and 5 is 3, which are evenly distributed on the end surface of the conductive ring, that is, the positions on the circumference of the conductive ring differ by 120 degrees, and the positions on the circumference of the left and right end surfaces of the conductive ring differ by 60 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com