Smoke guiding integrated stove

A technology of integrated stove and stove body, applied in the field of integrated stove, can solve the problems of low oil fume emission efficiency, increased noise, increased energy consumption, etc., and achieve the effect of improving fume exhaust efficiency and ensuring sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

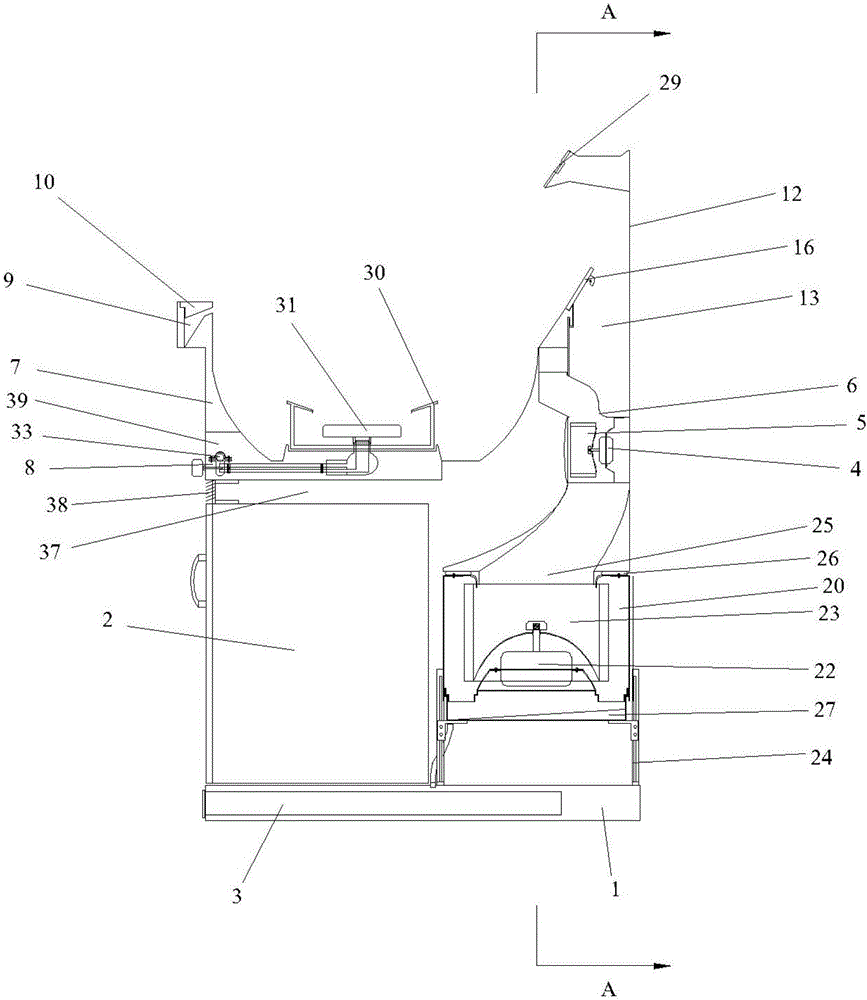

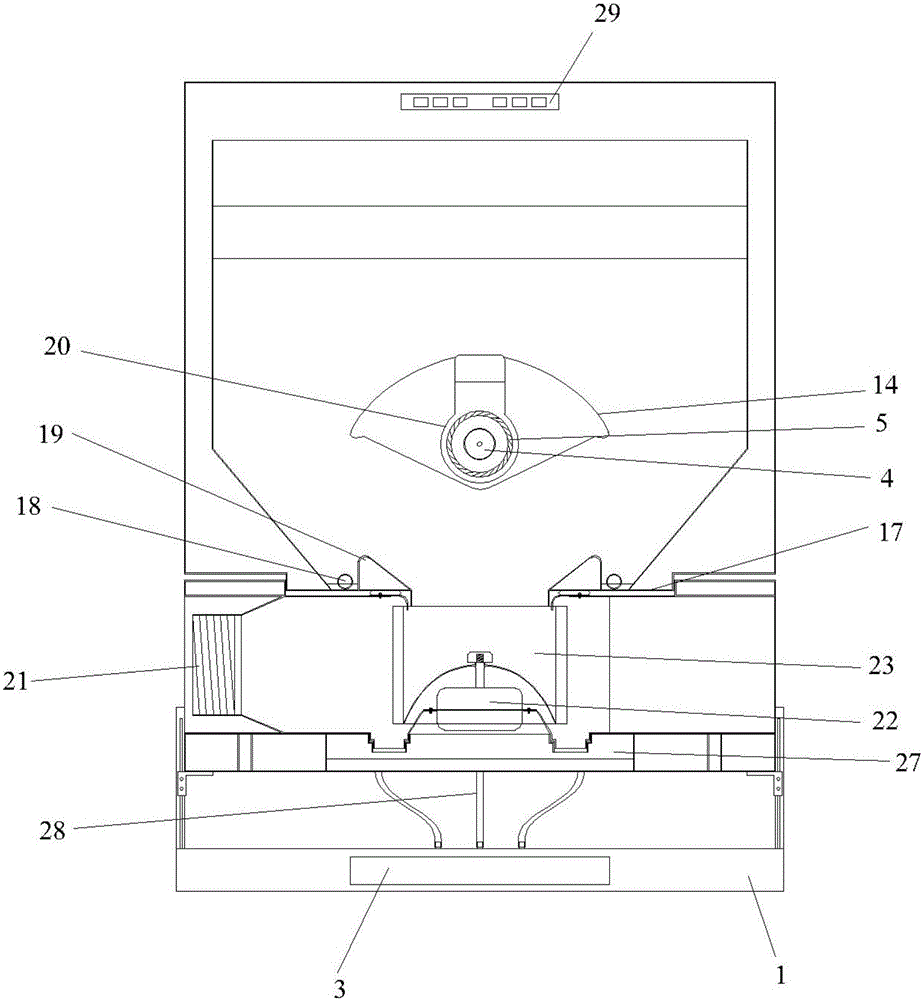

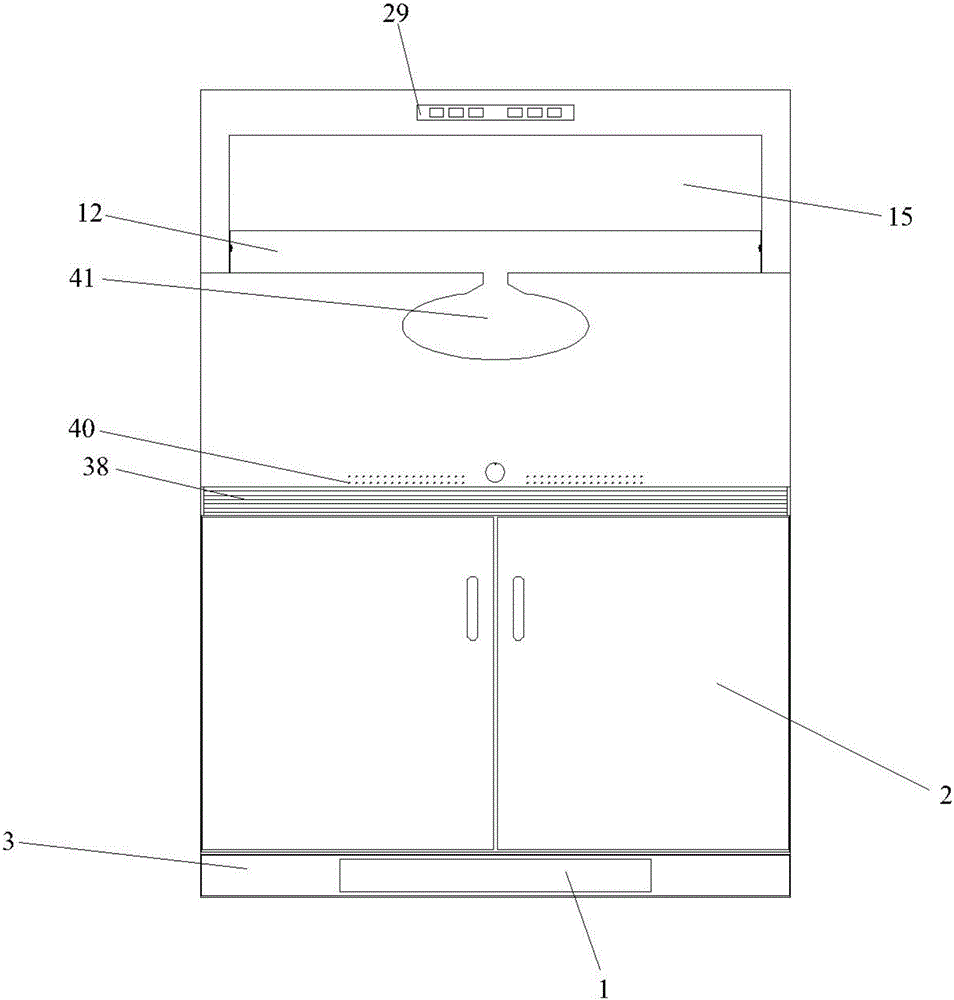

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] Such as Figure 1-6 As shown, the present invention includes a smoke protection and air guide mechanism, a smoke exhaust mechanism, a stove body, a locker 2 and a base 1, an oil storage box 3 is installed in a drawer type in the base 1, and the locker 2 is installed on the base 1 upper surface front.

[0034] The smoke protection and air guiding mechanism includes a blower motor 4, a blower wheel 5, a blower box 6, and a hemispherical shell 7, the hemispherical shell 7 is installed on the locker 2 with the opening facing upwards, and the hemispherical shell An air inlet passage 37 is provided between the body 7 and the locker 2, and a filter screen 38 is provided at the entrance of the air inlet passage 37. 7 outside the ignition device 8 is connected, the upper circumference of the hemispherical housing 7 is provided with an annular cavity 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com