Ice producing assembly and method for controlling temperature of ice producing cavity

A temperature control method and ice cavity technology, which are applied to refrigeration components, ice making, ice making, etc. Realize the effect of simplification and increase of ice storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

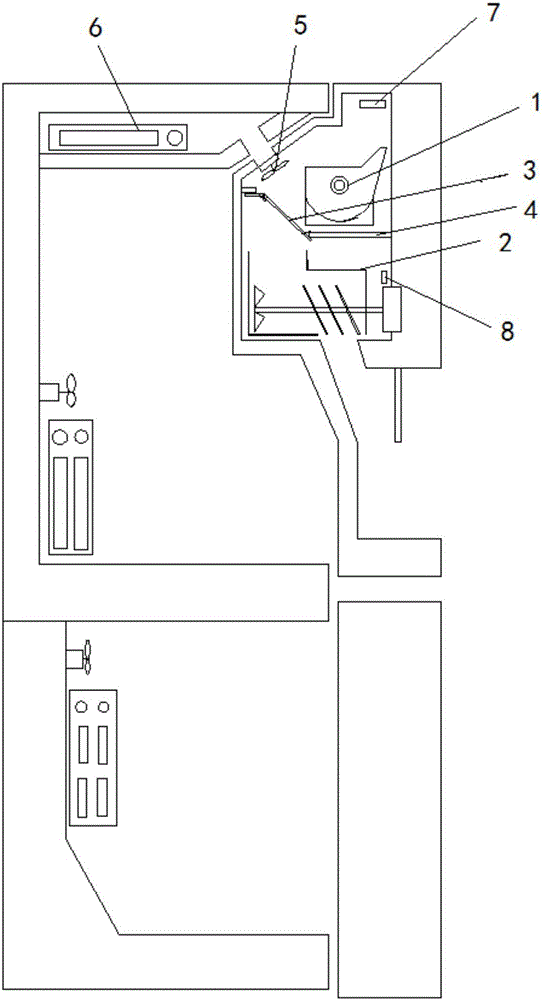

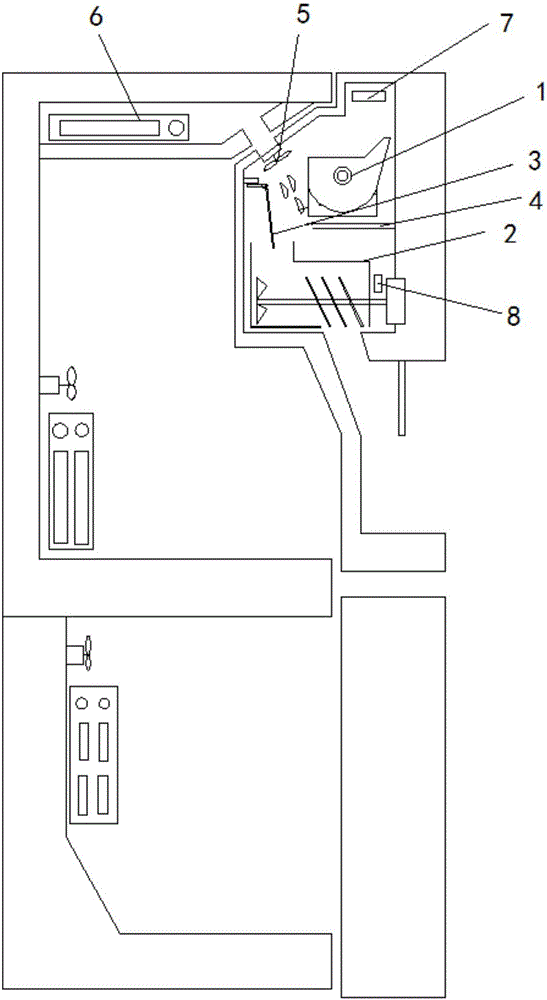

[0066] An ice-making assembly, including an ice-making chamber, an ice maker 1 installed above the inside of the ice-making chamber, and an ice storage box 2 located at the lower part inside the ice-making chamber, and also includes:

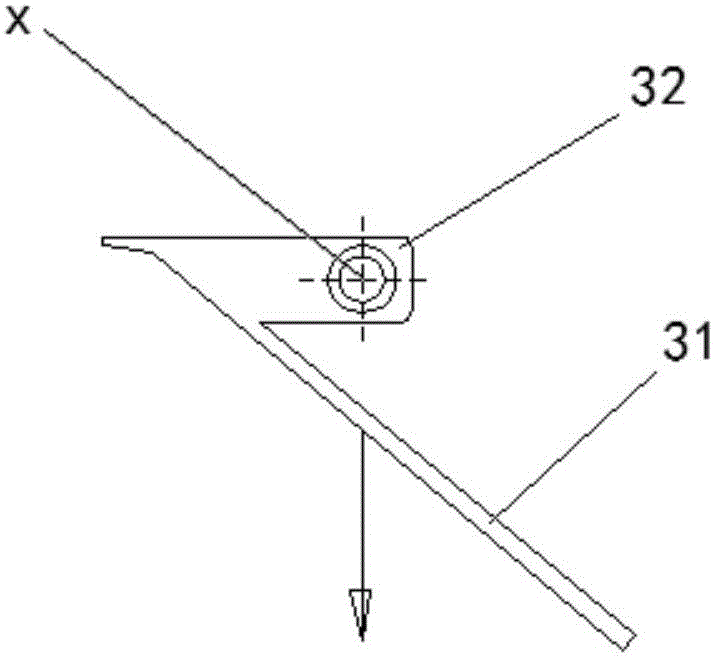

[0067] Movable partition 3, the movable partition 3 is arranged between the ice maker 1 and the ice storage box 2 for communicating or separating the ice maker 1 and the ice storage box 2, the movable partition 3 divides the ice making chamber The body is divided into two parts: the ice making area and the ice storage area;

[0068] A fan 5, the fan 5 is arranged at the opening at the upper end of the ice-making cavity, and the opening communicates with the cavity where the ice-making evaporator 6 is located and the ice-making cavity;

[0069] An ice storage area temperature sensor 8, the ice storage area temperature sensor 8 for collecting the actual temperature of the ice storage area is located at the lower part of the ice storage box and con...

Embodiment 2

[0088] An ice-making assembly, including an ice-making chamber, an ice maker 1 installed above the inside of the ice-making chamber, and an ice storage box 2 located at the lower part inside the ice-making chamber, and also includes:

[0089] Movable partition 3, the movable partition 3 is arranged between the ice maker 1 and the ice storage box 2 for communicating or separating the ice maker 1 and the ice storage box 2, the movable partition 3 divides the ice making chamber The body is divided into two parts: the ice making area and the ice storage area;

[0090] A fan 5, the fan 5 is arranged at the opening at the upper end of the ice-making cavity, and the opening communicates with the cavity where the ice-making evaporator 6 is located and the ice-making cavity;

[0091] An ice-making zone temperature sensor 7, the ice-making zone temperature sensor 7 for collecting the actual temperature of the ice-making zone is located above the ice maker 1 and connected to the inner wa...

Embodiment 3

[0111] Such as Figure 1-3 As shown, an ice-making assembly includes an ice-making cavity, an ice maker 1 installed above the inside of the ice-making cavity, and an ice storage box 2 located at the lower part of the inside of the ice-making cavity, and also includes:

[0112] Movable partition 3, the movable partition 3 is arranged between the ice maker 1 and the ice storage box 2 for communicating or separating the ice maker 1 and the ice storage box 2, the movable partition 3 divides the ice making chamber The body is divided into two parts: the ice making area and the ice storage area;

[0113] A fan 5, the fan 5 is arranged at the opening at the upper end of the ice-making cavity, and the opening communicates with the cavity where the ice-making evaporator 6 is located and the ice-making cavity;

[0114] An ice storage area temperature sensor 8, the ice storage area temperature sensor 8 for collecting the actual temperature of the ice storage area is located at the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com