Aluminum furnace feed device used for copper-aluminum compounding horizontal continuous casting

A horizontal continuous casting, copper-aluminum composite technology, applied in the direction of furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of complex automatic feeding equipment, high risk of manual feeding, high labor intensity, etc., to avoid aluminum liquid spraying The effect of splashing, simple structure and high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

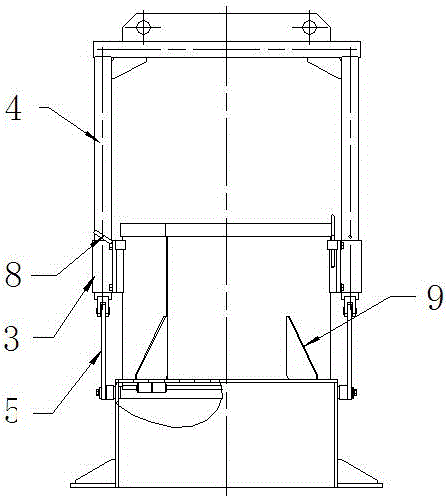

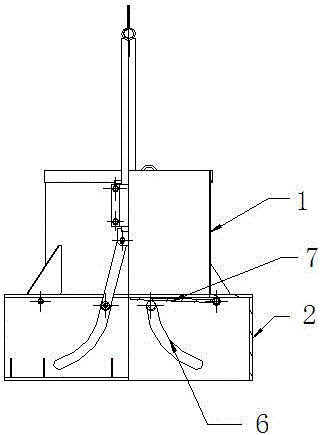

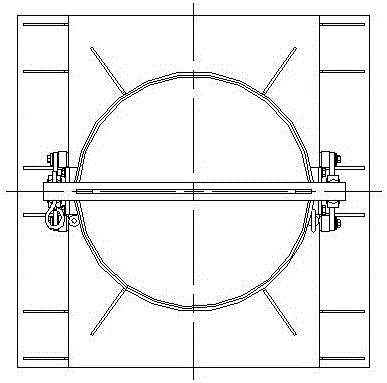

[0013] For better understanding and implementation, the present invention will be further described below in conjunction with accompanying drawing: the aluminum furnace feeding device that is used for copper-aluminum composite horizontal continuous casting, comprises charging cylinder 1, and charging cylinder diameter is slightly smaller than aluminum furnace mouth diameter, to ensure The block billet can enter the aluminum furnace smoothly, the barrel 1 is provided with reinforcing ribs 9, the barrel 1 is fixedly connected with the support 2 in the air, the two sides of the barrel 1 are provided with guide rods 3, and guide rods 4 are arranged inside the guide tubes 3. There is a limit hole in the vertical direction of the rod 4, and a pin 8 is arranged in the limit hole, and the conduit 3 is welded on the outside of the barrel 1 to ensure that the guide rod 4 can only move in the vertical direction, and the position of the guide rod is limited by the pin 8 . The guide rod 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com