Large mesh antenna reflector profile high-precision test method

An antenna reflector and testing method technology, which are applied in the directions of instruments, measuring devices, and optical devices, etc., to achieve the effects of improving measurement accuracy, improving accuracy, and improving profile testing accuracy.

Active Publication Date: 2017-05-10

XIAN INSTITUE OF SPACE RADIO TECH

View PDF5 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The technical problem solved by the present invention is: to overcome the deficiencies of the prior art, aiming at the large-caliber, small datum, and high-precision large-scale mesh antenna reflector, the datum extension tool is used to amplify the small datum and reduce the large size caused by the conversion of the small datum Error, through the design and layout of high-precision long reference rulers, and the use of optimized photogrammetry process parameters to improve the test accuracy of the photogrammetry system, thereby improving the surface test accuracy of large mesh antenna reflectors

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0032] The present invention will be described below by taking a typical large-diameter, small-standard, and high-precision mesh antenna reflector of a 15.6m large-scale mesh antenna reflector as an example.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

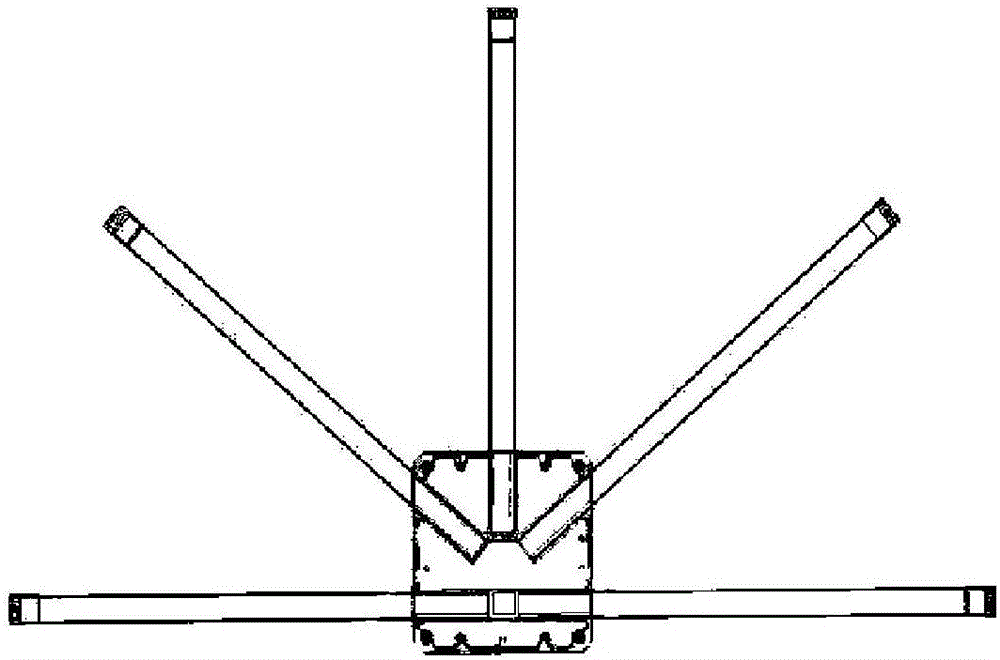

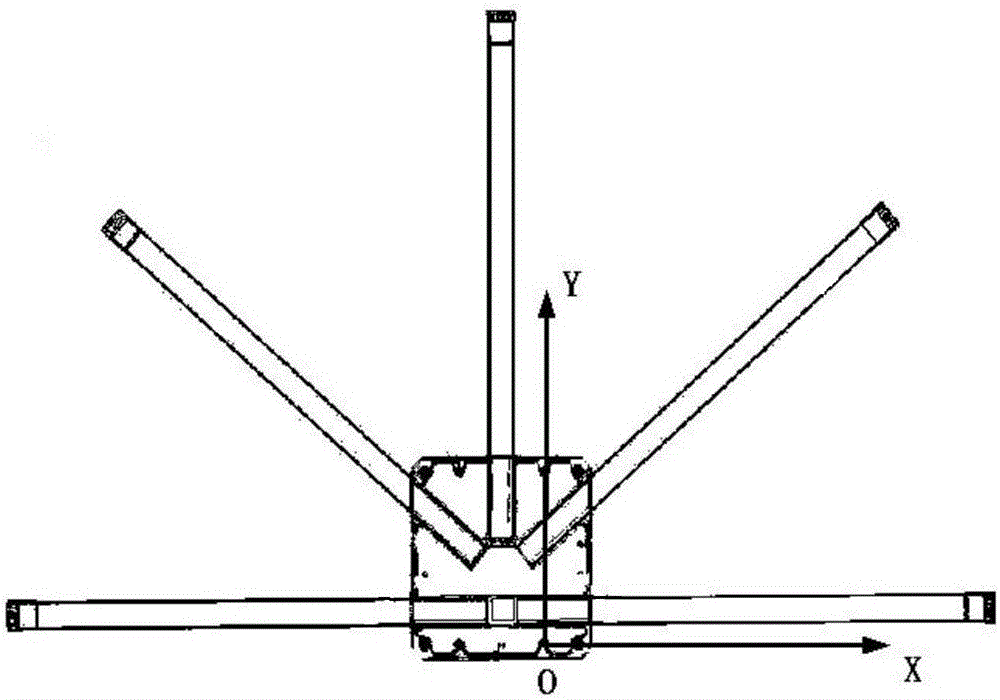

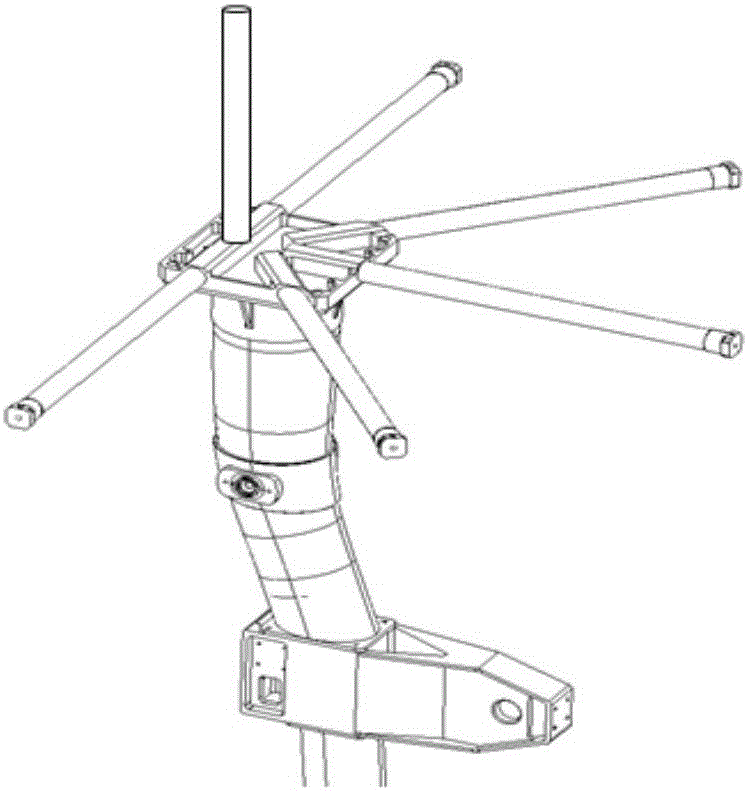

Login to View More Abstract

A large mesh antenna reflector profile high-precision test method is provided. By using high-precision industrial digital photogrammetry technology, a single camera is used for separately recording the images of the same scene in a space from different locations and directions. By means of image processing and according to known camera parameters, the three-dimensional coordinates of the scene relative to a coordinate system in the space are calculated. The profile precision of the mesh antenna is obtained by fitting the coordinate values with a theoretical profile. In order to improve the profile measurement precision of a large-caliber small-datum and high-precision large flexible mesh antenna reflector, by means of a designed reference conversion device, a high-precision long reference ruler, the large mesh antenna reflector profile is subjected to high-precision testing by optimal technological parameters of the photogrammetry system.

Description

technical field [0001] The invention relates to a method for testing the surface accuracy of a large mesh antenna reflector, belonging to the technical field of antenna mechanical measurement. Background technique [0002] The surface accuracy of the antenna reflector is an important index to measure and evaluate the quality of the antenna, and the surface accuracy of the antenna reflector will directly affect the electrical performance index of the antenna. At present, high-precision industrial digital photogrammetry technology is mostly used. This technology is based on the principle of binocular stereo vision 3D reconstruction. It uses a single camera to record images of the same scene in space from different positions and directions, and uses image processing to find the multiple 2D images. For the corresponding point, according to the known internal and external parameters of the camera, its three-dimensional coordinates relative to a certain coordinate system in space ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01B11/30G01B11/00

CPCG01B11/00G01B11/30

Inventor 蒲理华柏宏武段浩杨斌刘博学万小平王平康吕传景

Owner XIAN INSTITUE OF SPACE RADIO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com