MOEMS wireless vibration sensor based on comb grid and operation method thereof

A wireless vibration and sensor technology, used in instruments, signal transmission systems, measurement devices, etc., can solve the problems of high integration, small sensor size, difficult sensor layout and lead wires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and implementation method, the present invention will be further described:

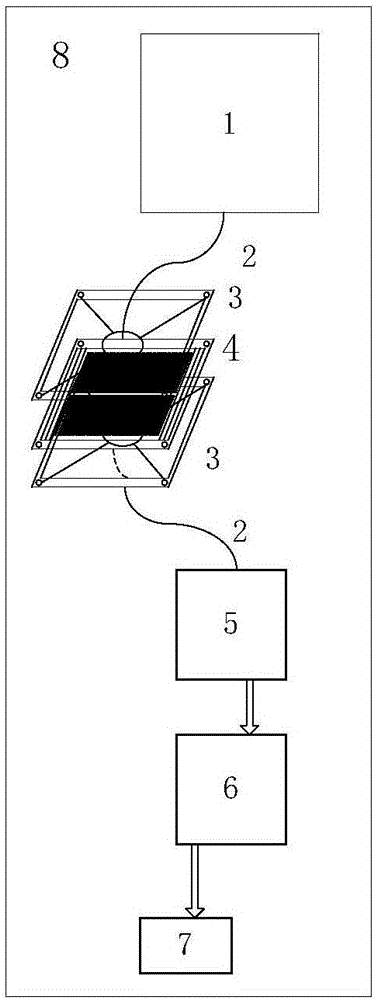

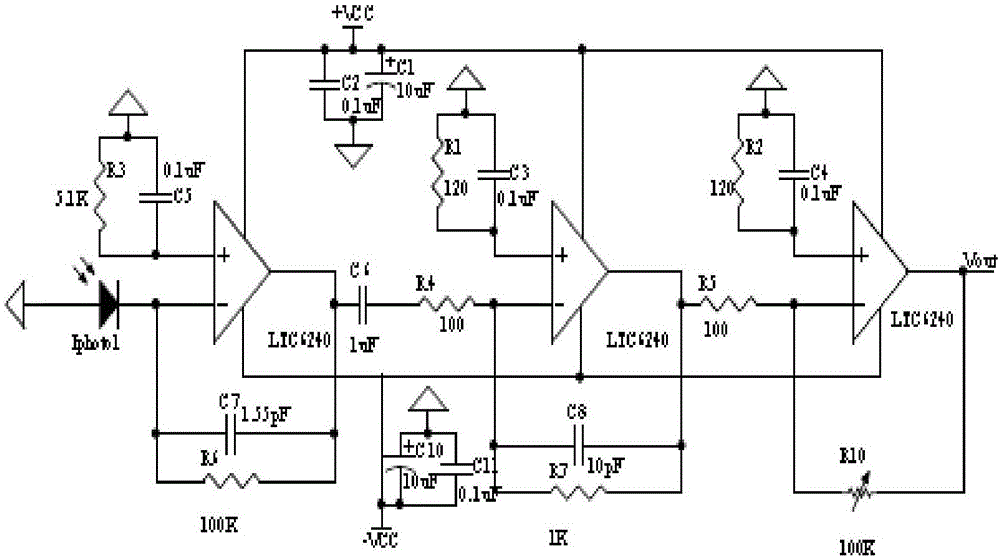

[0032] A MOEMS wireless vibration sensor based on a comb grid 11 mainly includes a sensor housing 8, a micro light source 1, a transmission fiber, a collimator 3, a vibration sensitive source 4, a photoelectric conversion module 5, a data analysis module 6 and a wireless transmission module 7 .

[0033] The MOEMS wireless vibration sensor is packaged in the sensor housing 8, and its modular and highly integrated design makes the sensor small in size, which overcomes the current situation that the existing optical fiber vibration sensor is difficult to arrange and lead in large-scale engineering monitoring projects such as tunnels and bridges.

[0034] The miniature light source 1 includes three parts: a power supply unit, a light emitting unit, and an output optical fiber pigtail 2 connected in sequence;

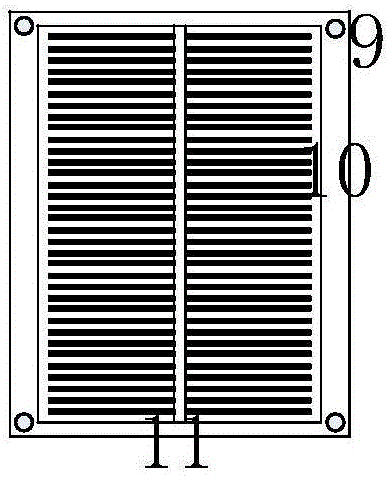

[0035] The vibration sensitive source 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com