Field programmable gate array (FPGA)-based industrial field temperature acquisition and alarm method and device

An industrial field and temperature acquisition module technology, applied to thermometers, measuring devices, and parts of thermometers, etc., can solve problems such as cumbersome process, difficulty in achieving high-speed temperature measurement, and slow processing speed of single-chip microcomputers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

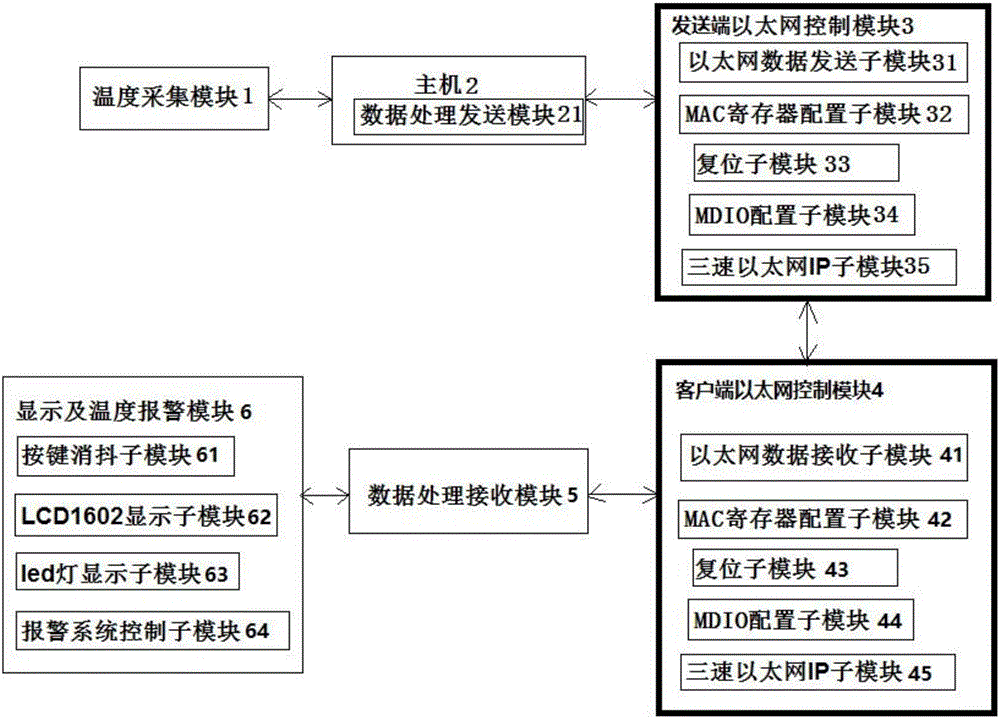

[0038] see figure 1 Shown, the whole temperature control process of the present application is as follows figure 1 shown. This application includes: a temperature acquisition module 1, a host computer 2, an Ethernet control module 3, a client data processing and receiving module 4, and a display and temperature alarm module 5. Wherein, the host is composed of FPGA, and the host 2 includes a data processing and sending module 21 .

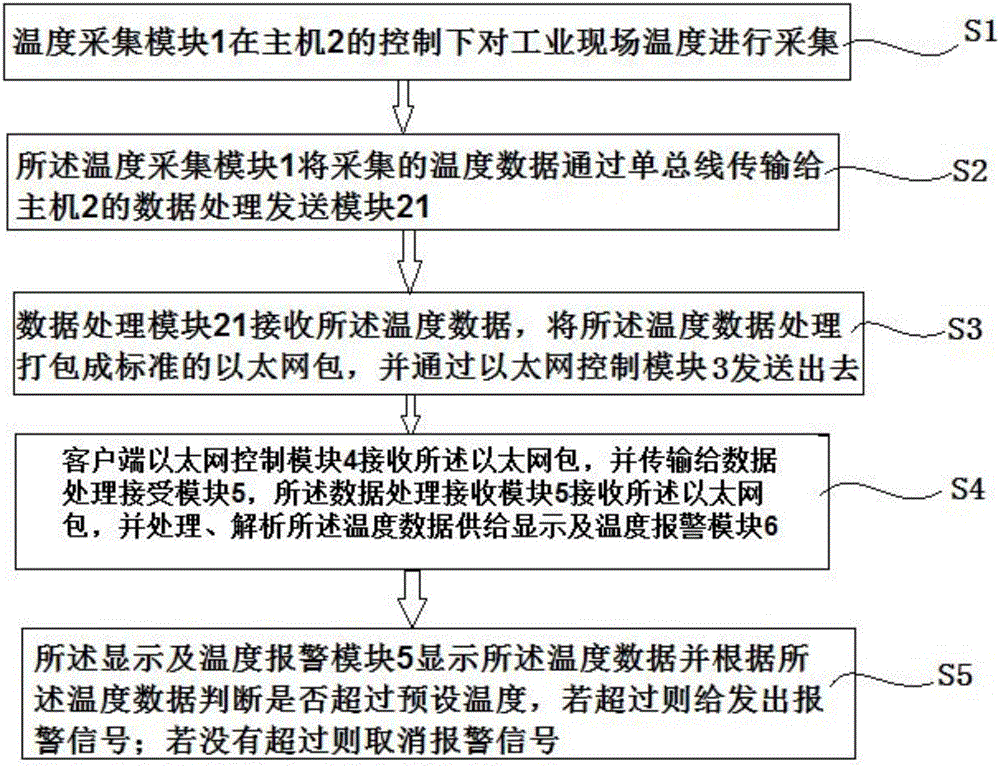

[0039] Such as figure 1 As shown, the temperature control process of this application is divided into 5 processes:

[0040] 1. The temperature collection module 1 collects the temperature of the industrial site under the control of the host computer 2 .

[0041] 2. The temperature collection module 1 transmits the collected temperature data to the data processing and sending module 21 through a single bus.

[0042] 3. The data processing sending module 21 receives the temperature data and processes the temperature data, packs it into a standard...

Embodiment 2

[0081] Embodiment 2 is an embodiment of an FPGA-based industrial on-site temperature acquisition and alarm device of the present application.

[0082] The FPGA-based industrial site temperature acquisition and alarm device of the present application includes a temperature acquisition module 1, a host computer 2 and a data processing and sending module 21 of the host computer, a sending end Ethernet control module 3, a client Ethernet control module 4, and a data processing receiving module 5 and display and temperature alarm module 6.

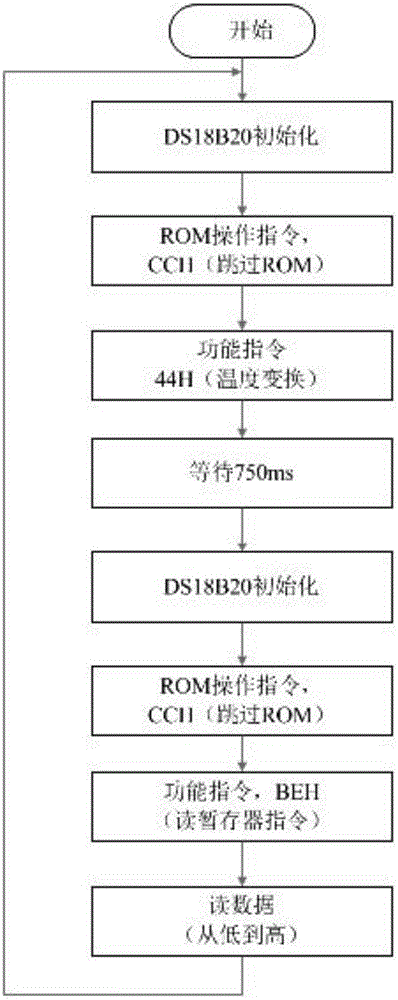

[0083] The temperature acquisition module 1 is set at the industrial site, and the temperature acquisition module is used for temperature acquisition at the industrial site. The temperature acquisition module 1 includes a plurality of temperature sensors, which can realize multi-channel temperature acquisition. The temperature acquisition module 1 transmits the temperature data to the data processing and sending module 21 through a single bus....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com