A Method for Detecting the Falling Strength of Green Pellets in Motion State

A technology of falling strength and motion detection, which is applied in the direction of strength characteristics, the use of applied repetitive force/pulsation force to test the strength of materials, measuring devices, etc., can solve the problems of poor accuracy of falling strength of raw pellets, avoid mutual collision and improve detection Efficiency, the effect of fast data processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

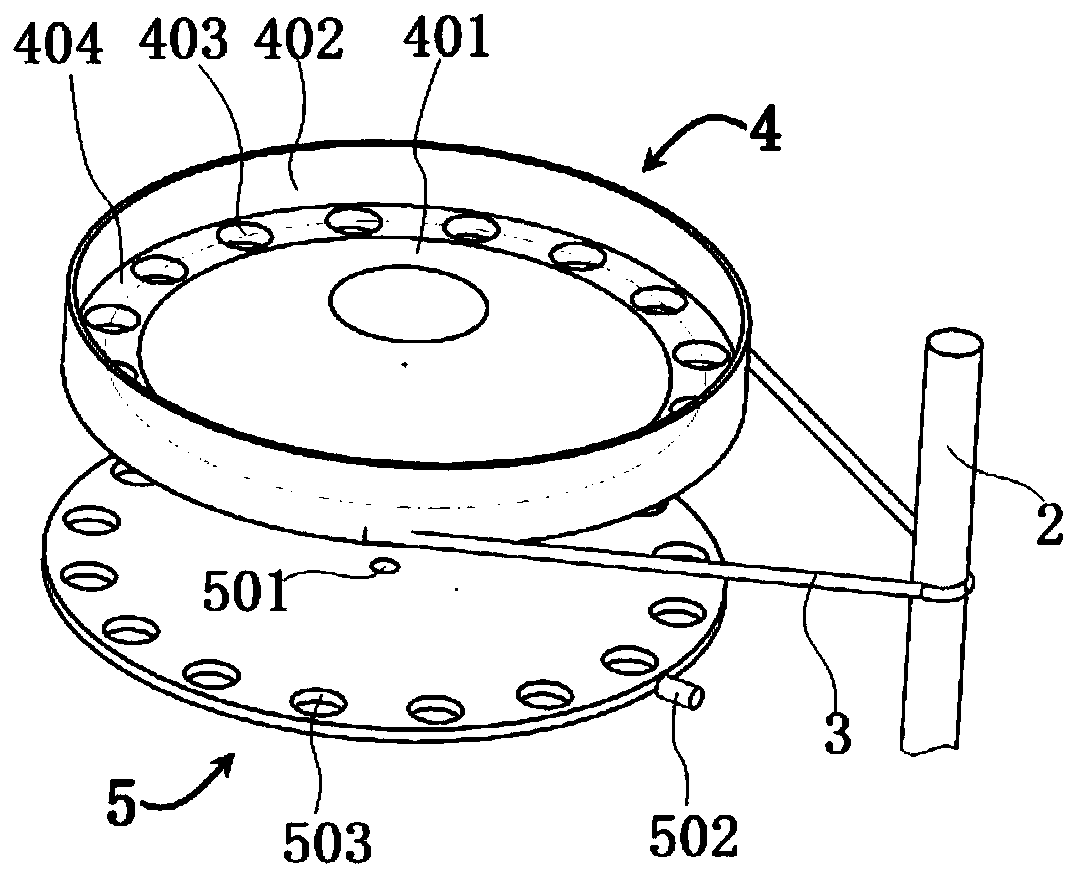

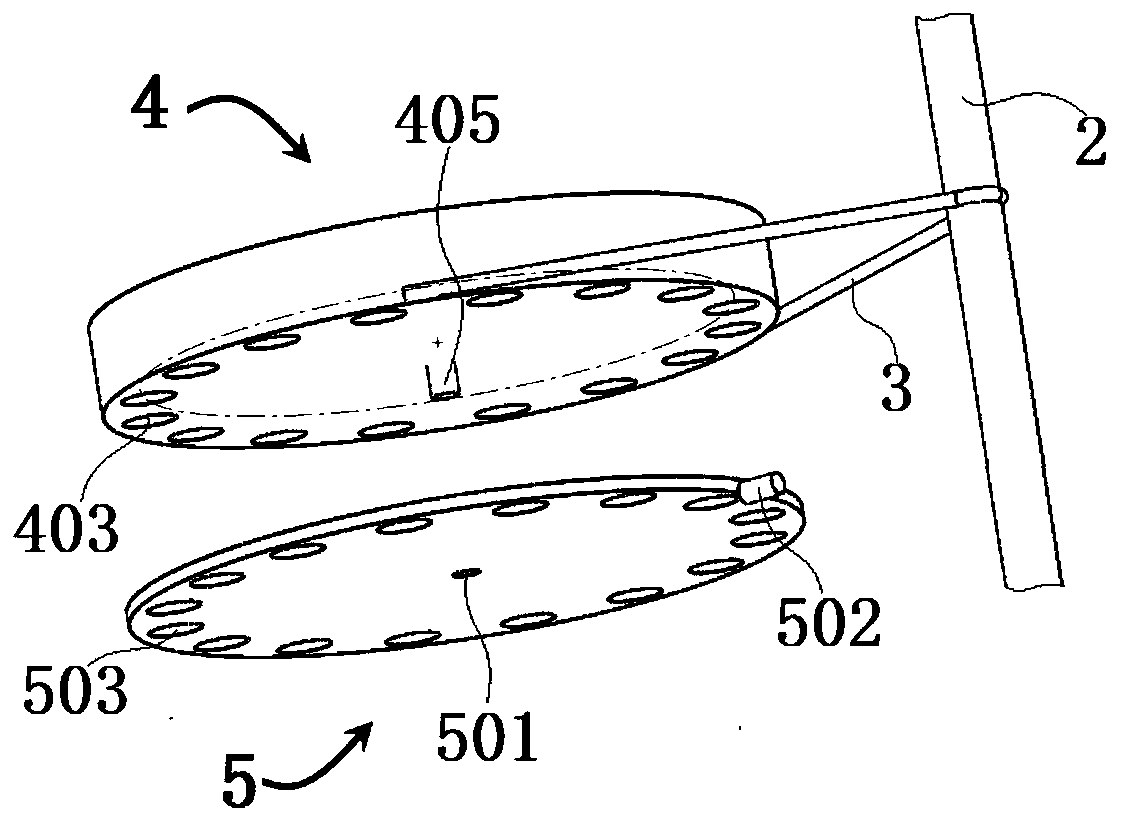

[0082] combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 9 and Figure 10 , the invention pioneered the design of a detection device specially applied to the falling strength of green pellets, which greatly improved the detection efficiency of the falling strength of green pellets while greatly improving the detection accuracy of the falling strength of green pellets. In addition, the present invention provides a brand-new detection method for the falling strength of green pellets, and creatively proposes simultaneous detection of the falling strength of multiple green pellets. The labor intensity of the operator is only 1 / 10 of the original detection method, which greatly improves The detection efficiency of the experimenters has outstanding substantive characteristics and has improved significantly.

[0083] A detection device for the falling strength of green pellets in a moving state according to the present invention, comprising a bottom plate 1, a suppor...

Embodiment 2

[0113] like Figure 5 As shown, the basic content of this embodiment is the same as that of Embodiment 1, the difference is that: the pellet dispersing mechanism 401 is a spherical protrusion, and the spherical protrusion extends to the edge of the upper pellet grate hole 403 through an arc surface. The green pellets are automatically dispersed into the upper pellet grate hole 403 under the action of the convexity of the spherical surface, preventing the aggregation of the green pellets during the falling process, and avoiding the mutual collision of the green pellets during the falling process.

[0114] The upper grate plate 404 is provided with 15 upper pellet grate holes 403, the diameter of the upper pellet grate holes 403 is 22 mm, and the diameter of the lower pellet grate holes 503 is 22 mm.

Embodiment 3

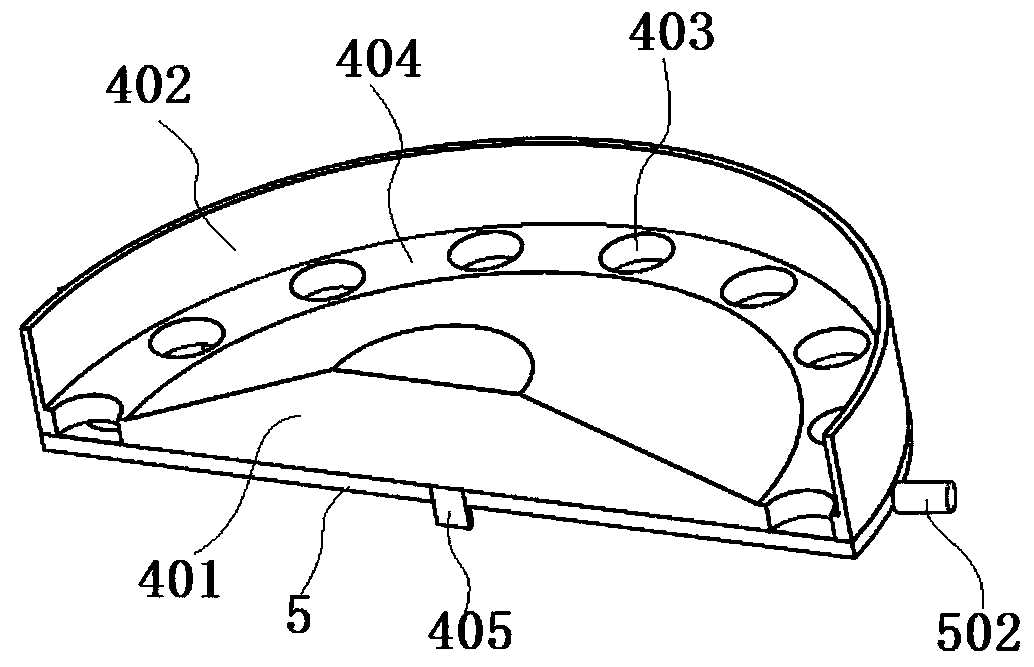

[0116] like Image 6 As shown, the basic content of this embodiment is the same as that of Embodiment 1. The difference is that the pellet dispersing mechanism 401 is a cone, and the bottom surface of the cone is connected to the upper surface of the upper grate plate 404. The peripheral edge of the bottom surface of the cone is An upper pellet grate hole 403 is arranged between the pellet baffle plate 402, and the upper pellet grate hole 403 is tangent to the peripheral edge of the conical bottom surface and the pellet baffle plate 402 respectively. Under the action of the cone, the green pellets are automatically dispersed from the side of the cone to the upper pellet grate hole 403, preventing the aggregation of the green pellets during the falling process, and avoiding the mutual collision of the green pellets during the falling process.

[0117] The upper grate plate 404 is provided with 30 upper pellet grate holes 403, the diameter of the upper pellet grate holes 403 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com