A pipeline endoscope probe into the tube auxiliary tooling

A technology for assisting tooling and endoscopes, applied in telescopes, instruments, optics, etc., can solve the problems of reduced probe rigidity, stuck probe, and large friction, so as to improve inspection results, prolong service life, and maintain costs. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings.

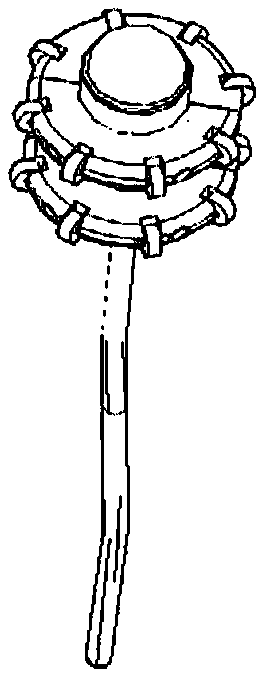

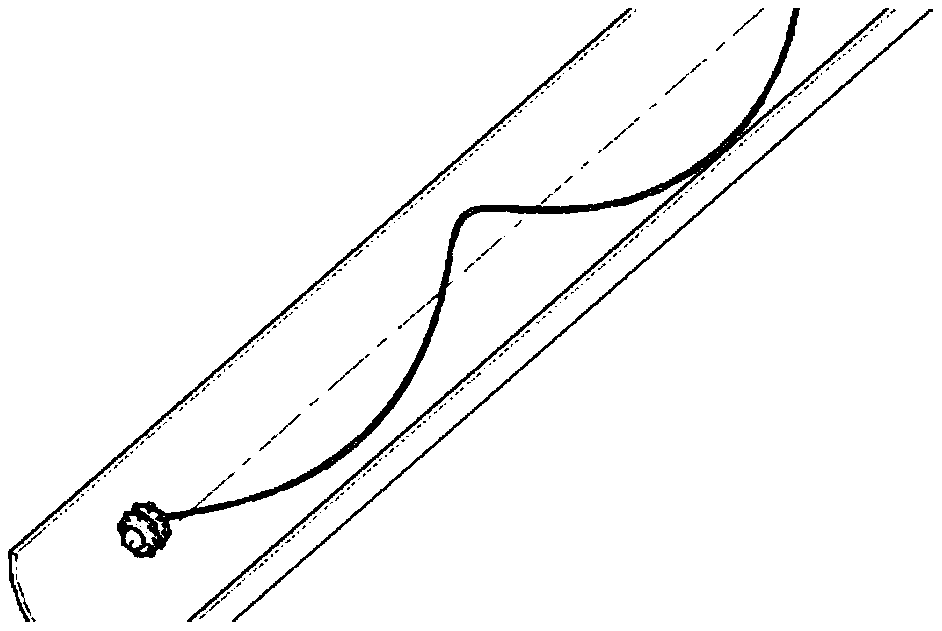

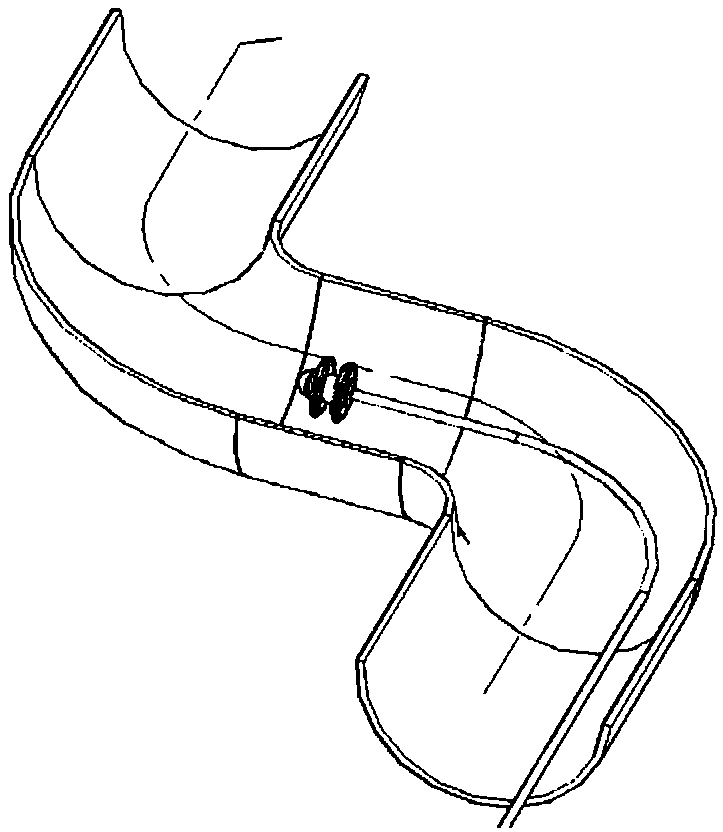

[0032] Please see first Figure 4 and Figure 5 , Figure 4 : The structural representation of the pipe endoscope of the present invention probing into the pipe auxiliary tooling, Figure 5 It is a structural schematic diagram of the cross clamp of the present invention, wherein a is a closed state, and b is an open state. As shown in the figure, a pipeline endoscope probes into the pipe auxiliary tooling, including a distance-keeping bar e and a plurality of cross clamps a fixed on the distance-keeping bar, and the cross-shaped four ends of the cross-clamp a Fixed pulleys b are respectively provided. The center of the cross clamp has a pipe clamp hole c, and the circumference of the cross clamp is provided with a pin hole d. The diameter of the probe hole c is the same as the diameter of the probe g. diameter, and the diameter of the pinch hole d is adap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com