Improved Offner optical system for detecting ultra-large-aperture concave aspheric mirror

An Ofner, ultra-large aperture technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of large compensator aperture and difficult to obtain materials, and achieve excellent image quality, easy parts processing, and high inspection accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

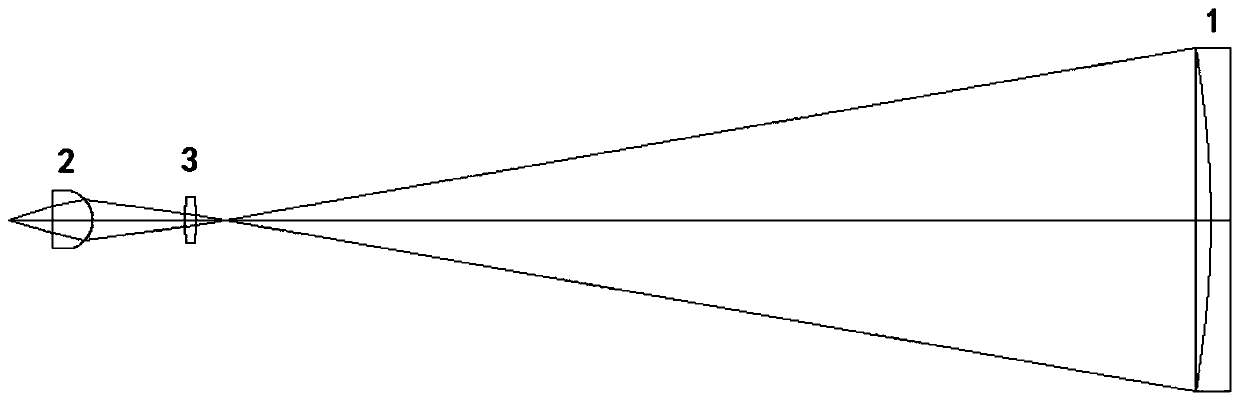

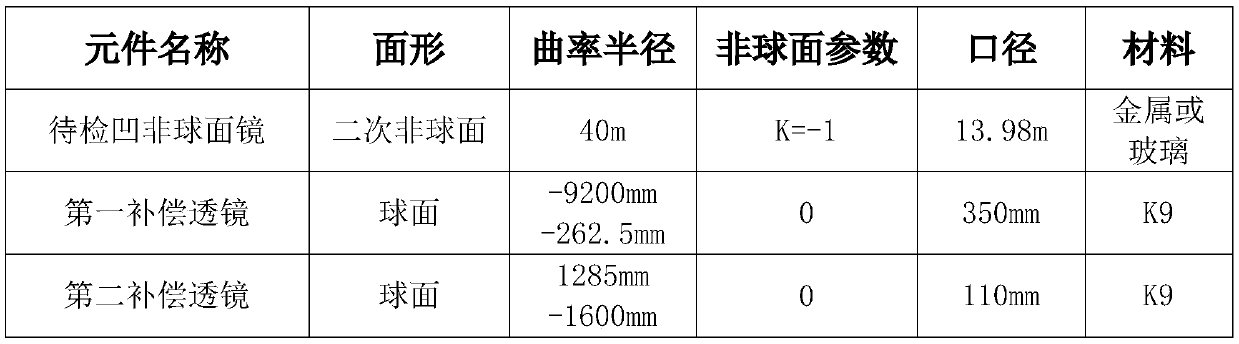

[0019] The present invention proposes an improved Offner inspection optical system for super-large-diameter concave aspheric mirrors, and the main technical indicators are as follows:

[0020] 1. Aperture ratio of the first compensator to the concave aspheric mirror to be inspected: 0.025;

[0021] 2. The ratio of the total incident ray aperture angle to the exit ray aperture angle of the compensation lens β=-1.71, and the ratio β of the incident ray aperture angle to the exit ray aperture angle of the first compensation lens 1 =-2.16, the ratio β of the incident ray aperture angle to the exit ray aperture angle of the second compensation lens 2 =0.79;

[0022] 3. The test aspheric surface diameter is 13.98m, the radius of curvature is 40m, and the relative aperture is 1 / 1.43;

[0023] 4. Check that the optical wave aberration PV value is better than 0.1λ (λ=633nm), and the RMS wave aberration is better than 0.025λ (λ=633nm).

[0024] The design parameters of the optical sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com