Surge protection circuit

A surge protection and protection circuit technology, applied in emergency protection circuit devices, circuit devices, emergency protection circuit devices for limiting overcurrent/overvoltage, etc. device malfunction and other problems, to ensure the performance of environmental adaptability, optimize the cost of the whole machine, and improve the reliability of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

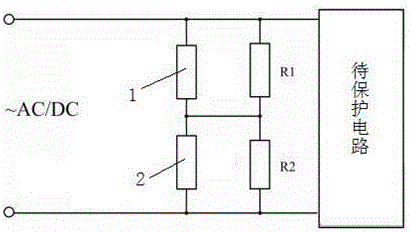

[0030] Comparison of surge protection schemes for ungrounded power supply or DC power supply of the whole machine: (this scheme can also be used as the second level of surge protection to reduce residual voltage)

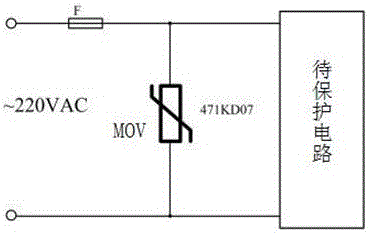

[0031] Such as figure 2 Shown is the traditional surge protection scheme, using varistors for differential surge protection;

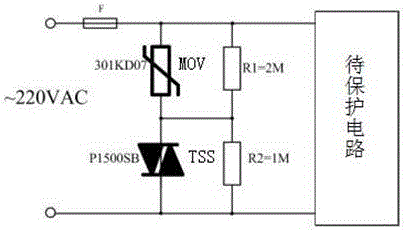

[0032] Such as image 3 It is shown that the surge protection circuit described in Embodiment 1 of the present invention uses the resistance ratio of the peripheral circuit, and adopts the method of connecting the piezoresistor TSS and the semiconductor discharge tube MOV in series to make a differential surge protection circuit; image 3 The protection circuit shown uses the resistance ratio of the voltage dividing matching circuit to distribute the voltage at both ends of the protection device fixedly. Under the normal operation of the circuit, the voltage at both ends of the varistor TSS is 2 / 3 times of the input voltage Vin of the power...

Embodiment 2

[0035] Comparison of surge protection schemes for whole machine grounding power supply:

[0036] Such as Figure 6 : The traditional surge protection scheme uses varistors for differential protection, and uses varistors and gas discharge tubes in series for common mode protection. Due to the large difference in dynamic parameters between varistors and discharge tubes, the varistor and gas discharge The tube selects the voltage model according to the input power Vin;

[0037] Such as Figure 7 Shown is the surge protection circuit described in Embodiment 2 of the present invention, using a voltage division matching circuit to fix the voltage across the varistor MOV and the ceramic gas discharge tube GDT according to the resistance ratio of the resistors; image 3 The resistance matching is designed in the middle. Under normal power supply conditions, the voltage at both ends of the varistor MOV is 2 / 3 times of the input power Vin, and the voltage at both ends of the ceramic g...

Embodiment example 3

[0040] The case grounding of the whole machine has withstand voltage requirements Comparison of surge protection schemes for power supply products

[0041] Such as Figure 10 Shown is the traditional surge protection scheme, using varistors for differential protection, and using varistors and discharge tubes in series for common mode protection. Due to the HI-pot withstand voltage requirements, the breakdown voltage of discharge tube products is required to be Greater than 1500Vac;

[0042] Such as Figure 11Shown is the surge protection circuit described in Embodiment 3 of the present invention, using the impedance distribution of the voltage division matching circuit to fix the voltage at both ends of the protection device; as shown in the scheme above, under normal 220Vac power supply, the voltage at both ends of the varistor MOV It is 2 / 5 times of the power input vin, and the voltage across the ceramic gas discharge tube GDT is 3 / 5 times of the power input; when making 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com