Combined iron core motor

A heart motor and mixed iron technology, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve the problem of large current ripple, small inductance, Increased magnetic circuit reluctance and other issues, to achieve the effect of light weight, good torque characteristics, and increased motor inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

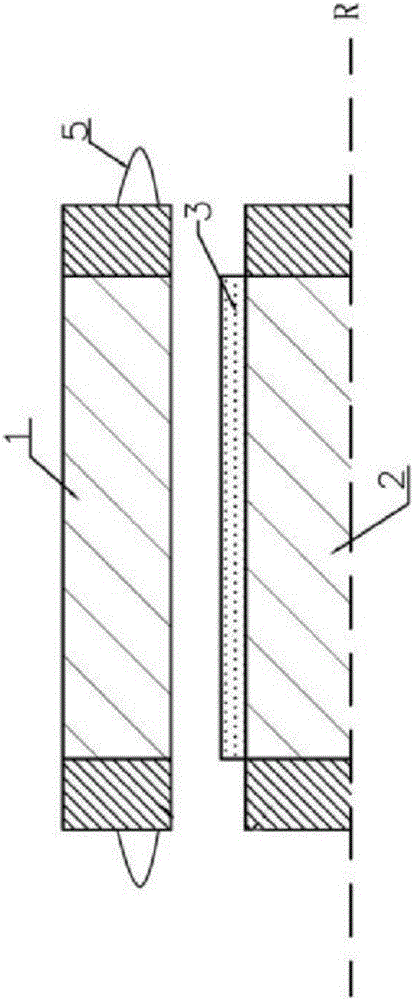

[0015] refer to figure 1 , a hybrid core motor, including a stator 1 and a rotor 2, the yokes of the stator 1 and the rotor 2 both have a hybrid core structure, and the hybrid core structure is an auxiliary core layer, a non-magnetic material layer and the auxiliary core layer, the auxiliary core layer is a magnetically permeable material component, the non-magnetically permeable material layer is a non-magnetically permeable material component, and the teeth and the yoke of the stator 1 are integrally formed.

[0016] In this embodiment, the magnetically permeable material member is a silicon steel member, and the non-magnetically permeable material member is an epoxy resin member.

[0017] The auxiliary core layer and the non-magnetic material layer are connected and fixed by screws.

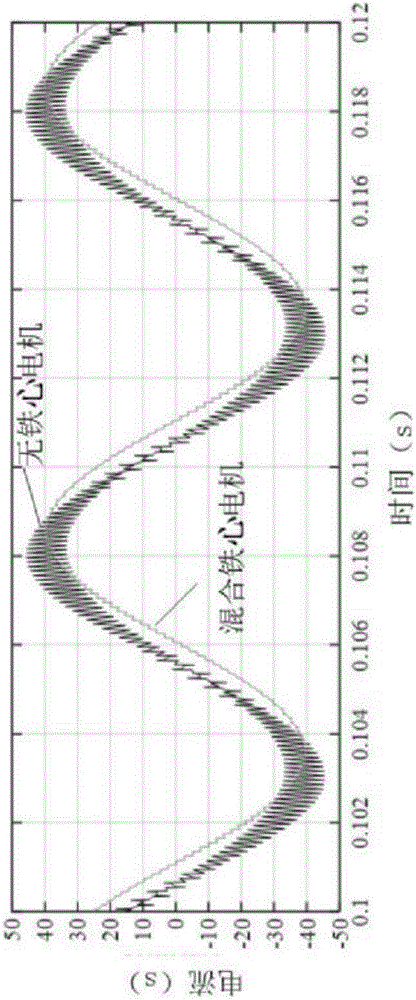

[0018] In order to eliminate cogging torque and iron loss and reduce heat generation, the coreless motor uses lighter non-magnetic materials as the stator teeth, yoke and rotor yoke, instead ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com