Turbomachines including means for decoupling fans

A technology of coupling device and turbine, which is applied to the components of pumping device for elastic fluid, pump device, safety device, etc., can solve the problems of increasing the aerodynamic resistance of the engine, the inability of the fan to rotate, and the inability of the aircraft to drive.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

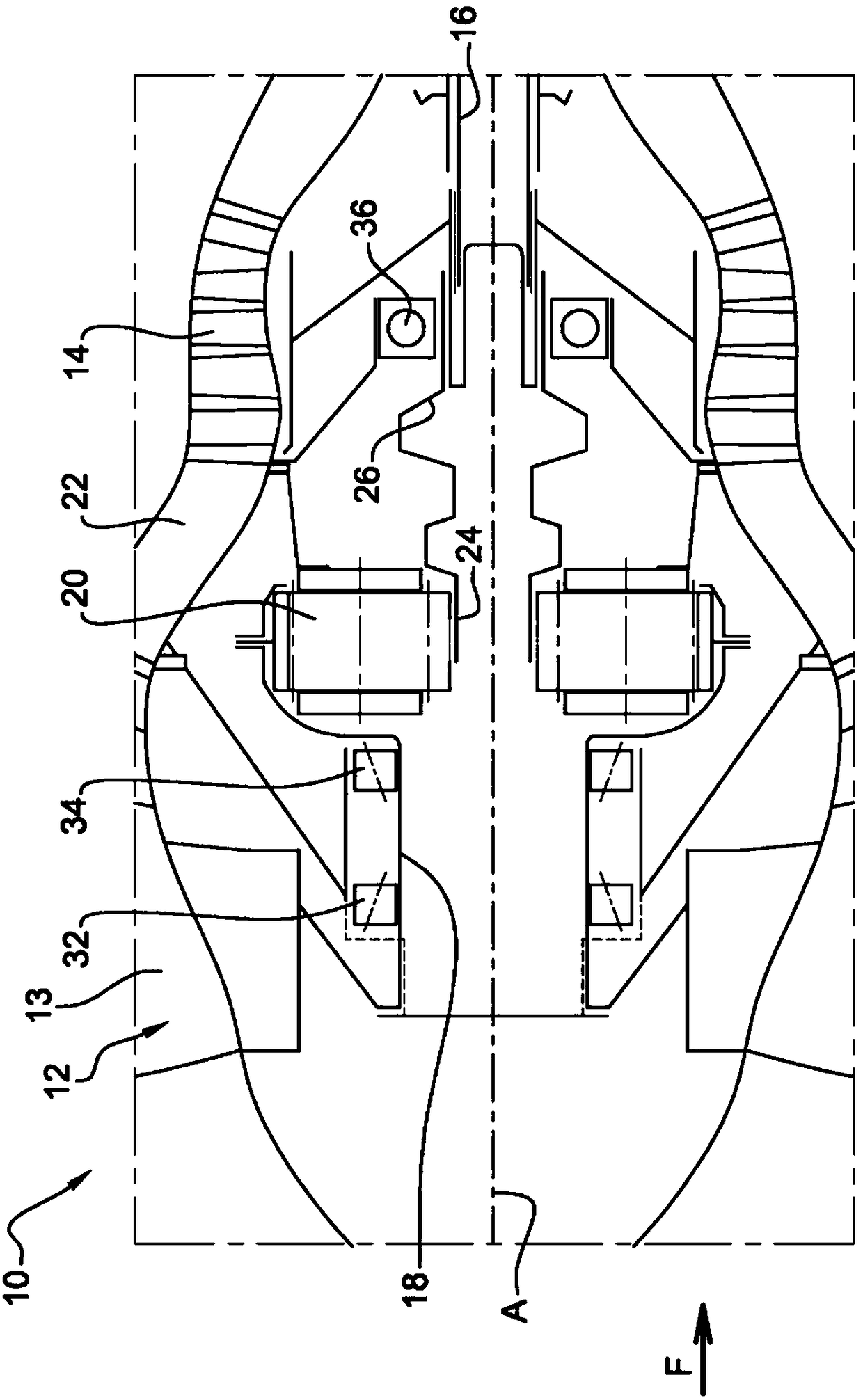

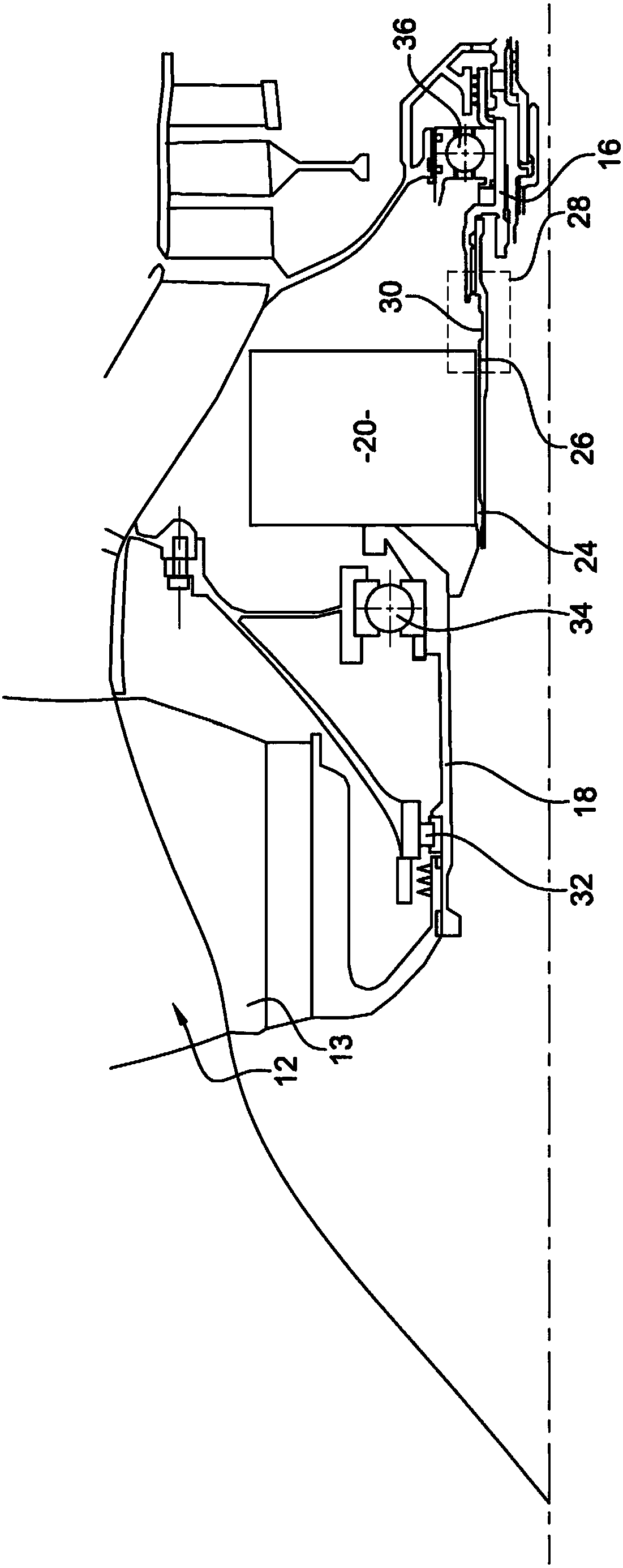

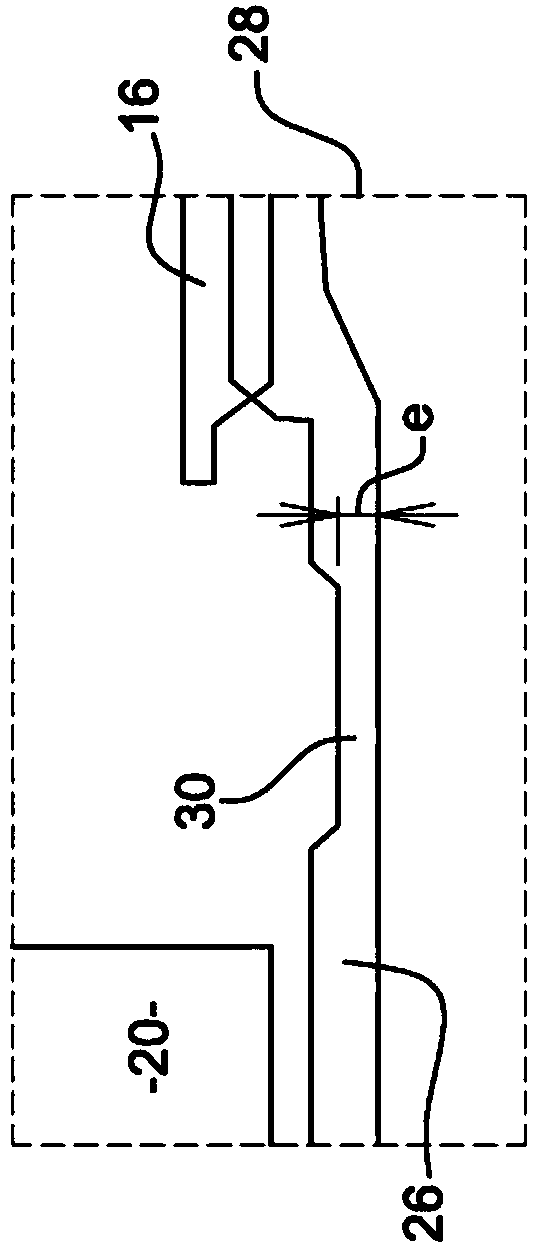

[0029] In the following description, the same reference numerals designate the same components or have similar functions.

[0030] exist figure 1 A turbine, such as a turbine engine 10, made according to the state of the art is shown in . In known manner, the turbine engine 10 includes, from upstream to downstream along airflow flow "F", a fan 12 , a low pressure compressor 14 , a high pressure compressor, a combustor, a high pressure turbine and a low pressure turbine (not shown). The fan 12 includes blades 13 . The high-pressure compressor and the high-pressure turbine are connected by a high-pressure shaft and together with the high-pressure shaft form a high-pressure body. The low-pressure compressor 14 and the low-pressure turbine are connected via a low-pressure shaft 16 and together form a low-pressure body. As regards the fan 12 , it is supported by a fan shaft 18 which, in the example shown, is rotationally coupled to the BP shaft 16 by means of a device 20 for red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com