Aluminum oxide belt conveying system and method

A technology of belt conveyor and belt conveyor, which is applied in the field of alumina transportation, can solve the problems of easy wear and tear of the conveying pipe, low work efficiency, and large manual labor, so as to shorten the fault handling time, improve work efficiency, and have a high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

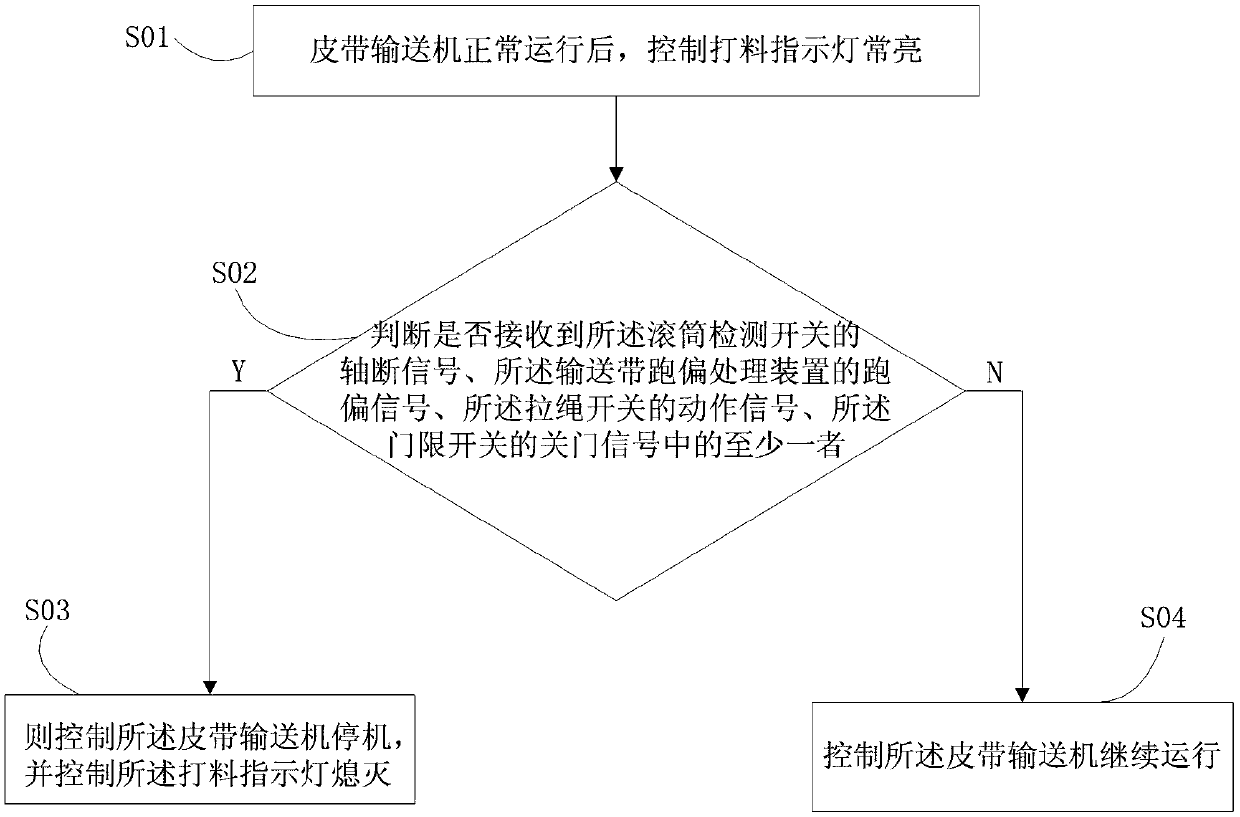

[0025] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. The alumina belt conveying system 100 provided by the present invention is mainly used for conveying alumina in the electrolysis plant area, but not limited thereto, and can also be used for conveying other similar items.

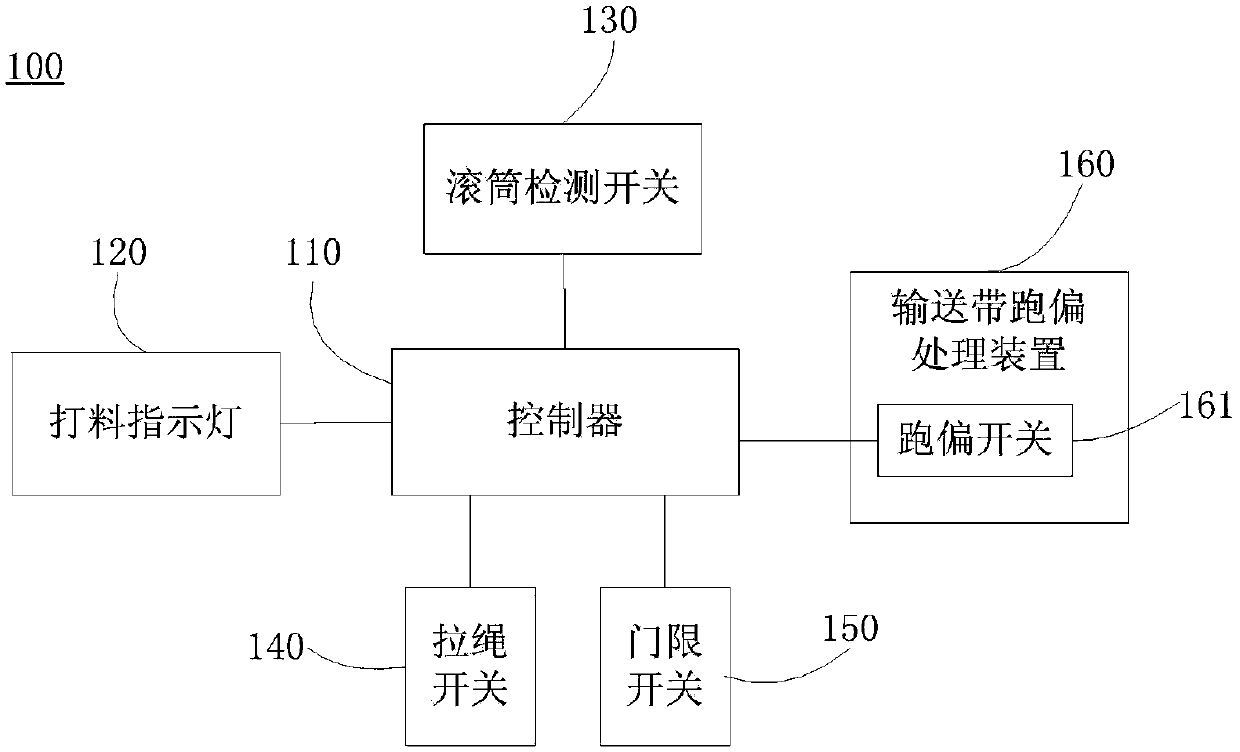

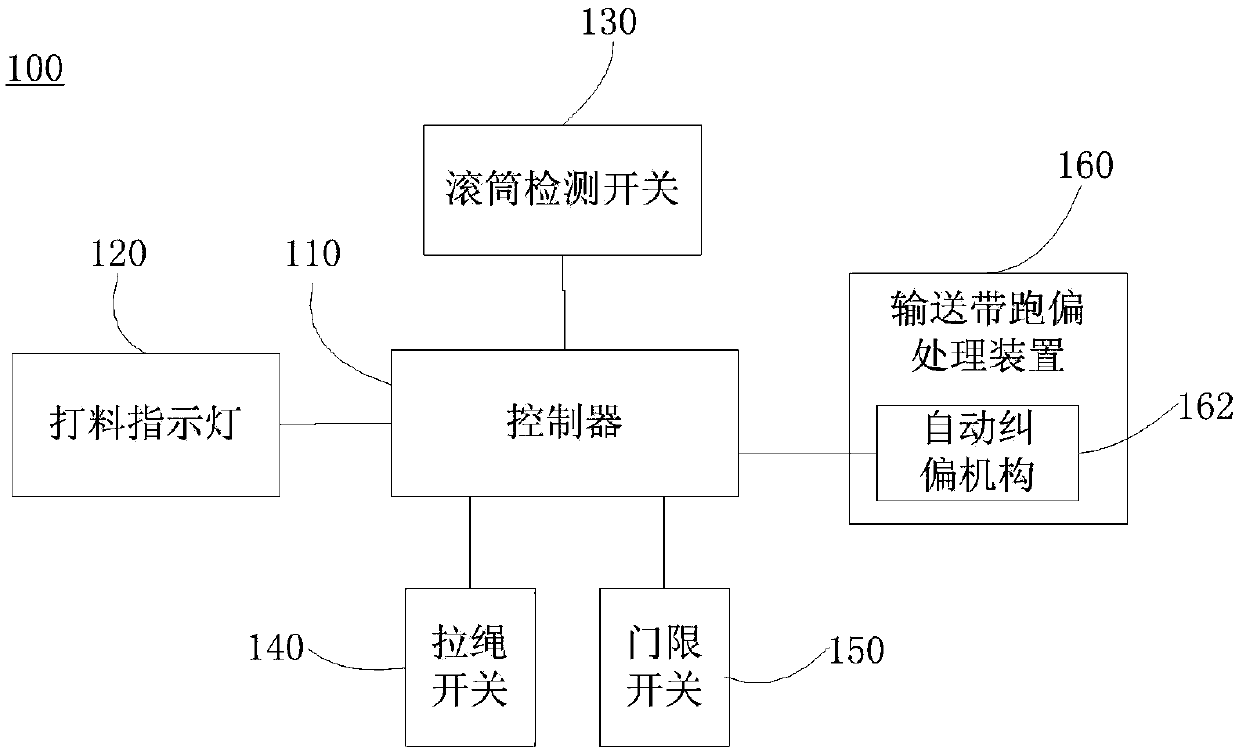

[0026] Combine first figure 1 , figure 2 As shown, the structure of the alumina belt conveyor system 100 provided by the present invention will be described. Specifically, the alumina belt conveyor system 100 includes a belt conveyor (not shown in the figure), a controller 110, a material control indicator 120, a drum detection switch 130, a rope switch 140, a threshold switch 150, and a conveyor belt deviation The processing device 160, and the belt conveyor, the feeding control indicator light 120, the roller detection switch 130, the rope switch 140, the threshold switch 150, and the conveyor belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com