Metal gasket

A technology of metal gaskets and metal plates, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problem of being unable to cope with the narrowing of the width of the sealing surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0079] Next, embodiments of the present invention will be described with reference to the accompanying drawings.

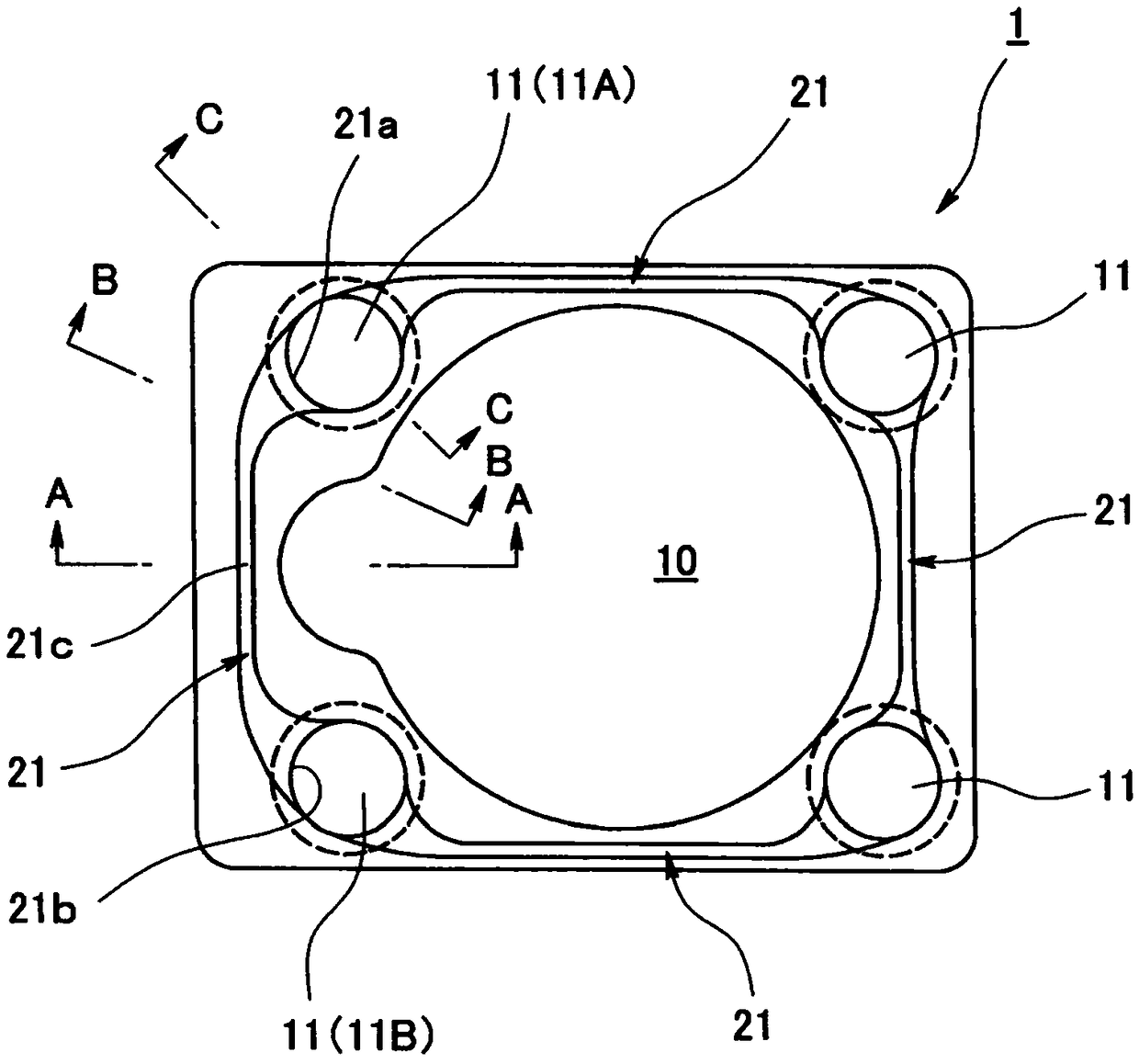

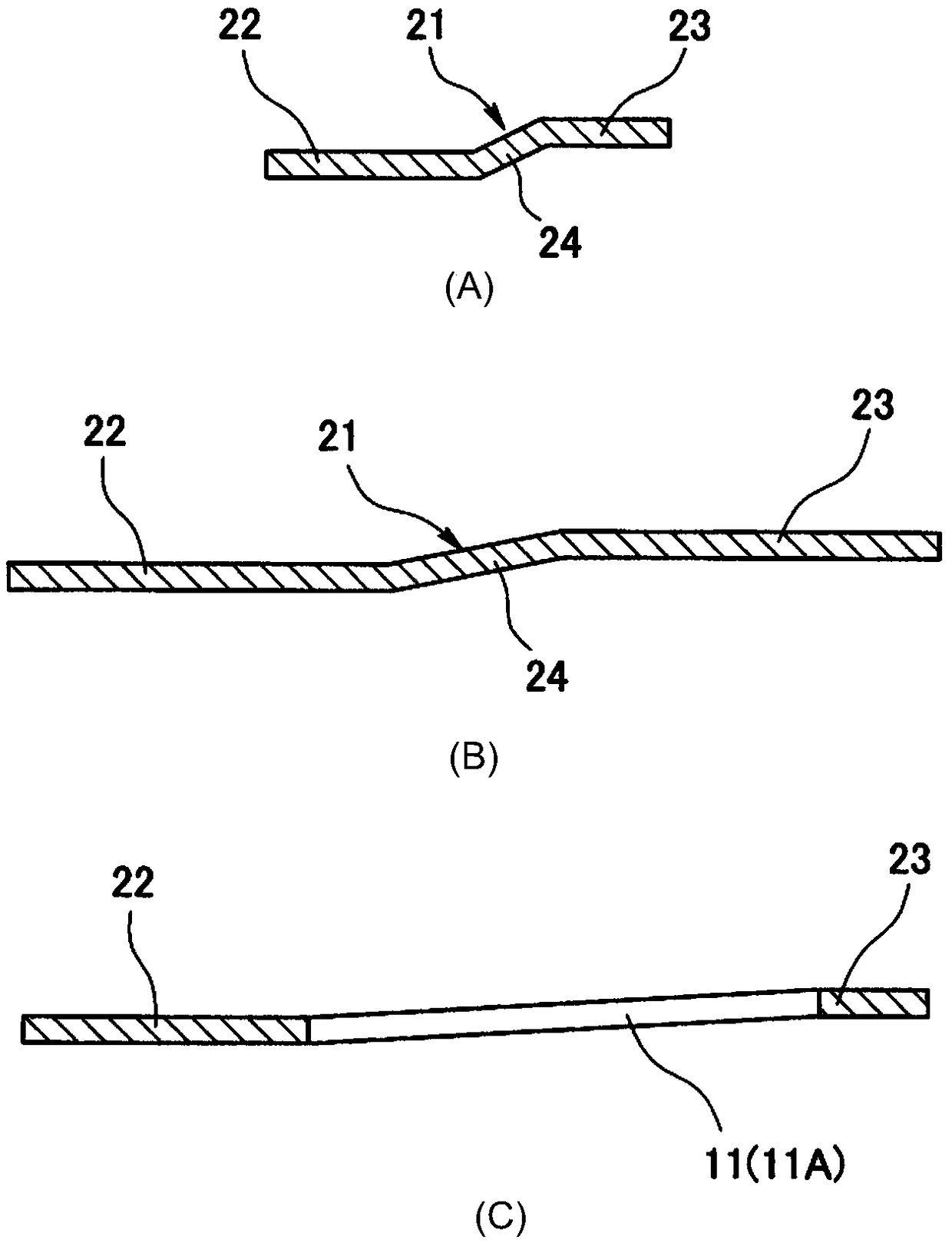

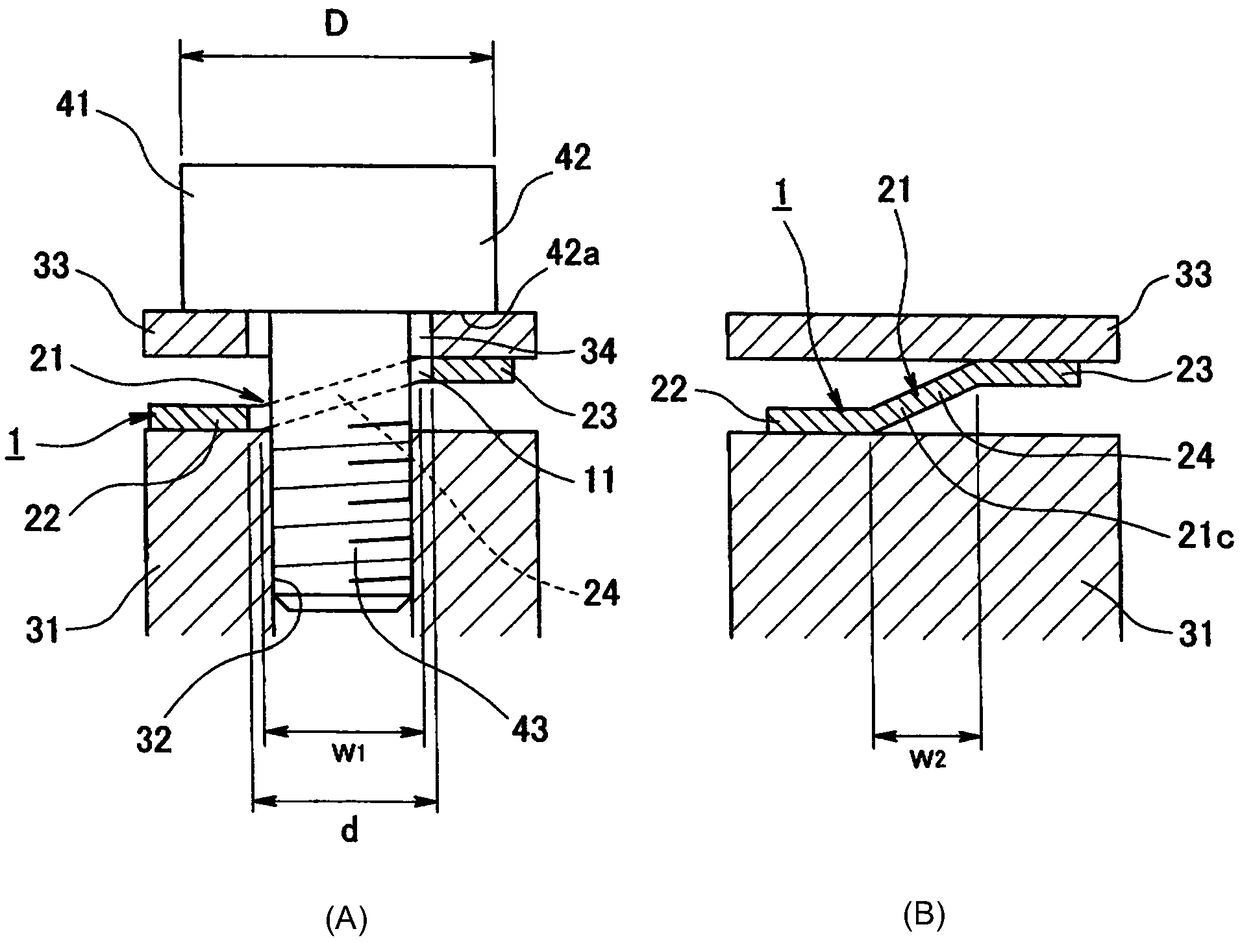

[0080] figure 1 as well as figure 2 Indicates the metal spacer in the embodiment of the present invention. The metal gasket 1 in this embodiment is a flat metal gasket mounted on a flange portion of an engine or auxiliary machine, EV (electric vehicle), HEV (hybrid electric vehicle) inverter, etc. in vehicles such as automobiles, It has a prescribed plane layout (rectangular plane in the figure), and on this plane, there are holes 10 and a plurality of bolt holes 11 (four places in the figure), and the internal pressure and outside water (external foreign matter) should be sealed at the same time. The sealing rib 21.

[0081] Such as figure 1 As shown, a plurality of bolt holes 11 are arranged on the flat plate of the metal gasket 1 , and sealing protrusions 21 are arranged between the bolt holes 11 adjacent to each other. In the figure, there are four bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com