Soil-free turf and production device thereof

A technology for soilless lawn and production equipment, which is applied in soilless cultivation, botanical equipment and methods, planting substrates, etc., can solve the problems of poor fruiting, scattering, and inability to truly ensure the density of sowing, and achieve low cost. , good effect of forming flat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

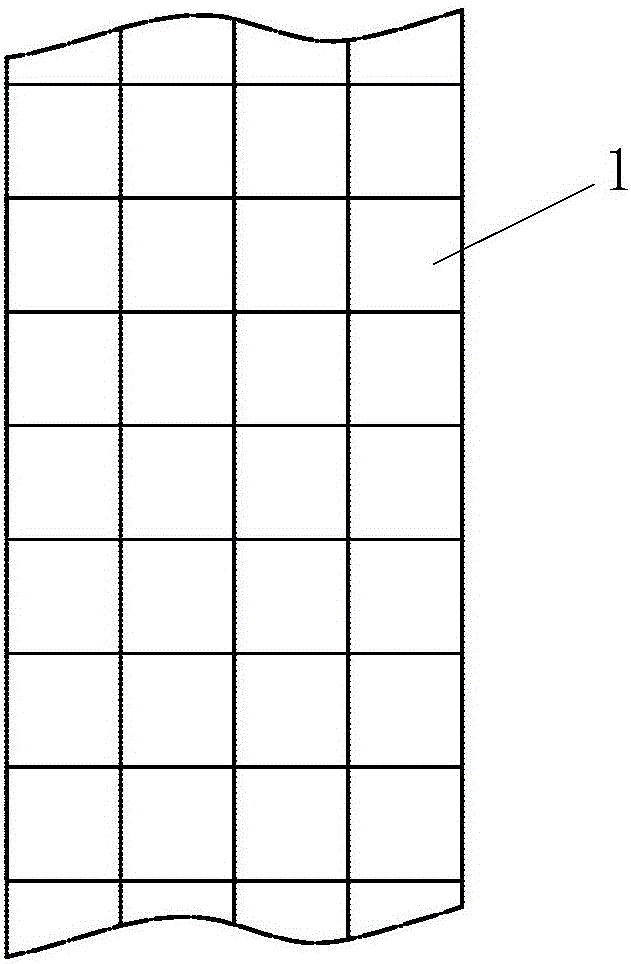

[0027] Such as figure 1 Shown, a kind of soilless lawn of the present invention, comprises the non-woven bag 1 that is arrayed in matrix and is respectively placed in each lawn grass seed and fertilizer in non-woven bag 1, and fertilizer is nutrient base or slow-release fertilizer etc., Of course, water-retaining agents or other additives needed to grow lawns can also be added to the fertilizer. The edges of adjacent non-woven bags 1 are connected to each other, so that the non-woven bags 1 arranged in a matrix are connected into a block structure that can be directly laid on the terminal planting site. In the present embodiment, the non-woven bag 1 is a square, and of course the non-woven bag can also be a rectangle as a modified form of the present invention. The soilless lawn of the present invention can be industrialized before being sold, and can be rolled up and placed in a warehouse after production. After being sold, it can be directly spread on the terminal planting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com