Automatic feeding method based on square silkworm rearing frame

A square, automatic technology, applied in animal husbandry and other directions, can solve the problems of feed accumulation, increase labor intensity, and low survival rate of ants and silkworms, and achieve the effect of increasing the placement area, improving stability and reliability, and ensuring the placement thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

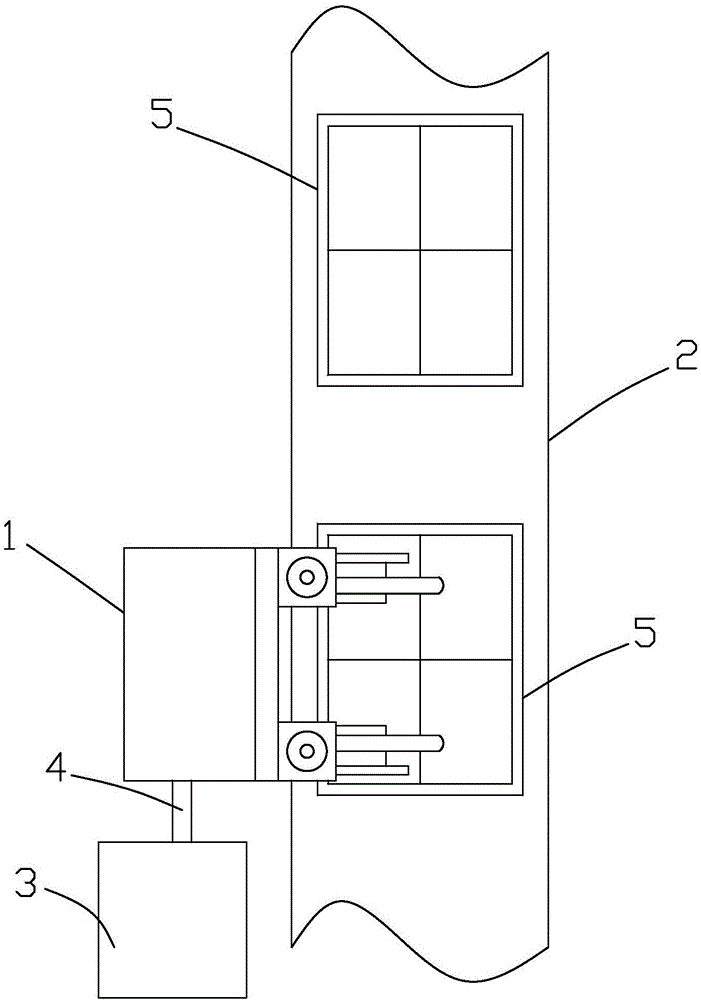

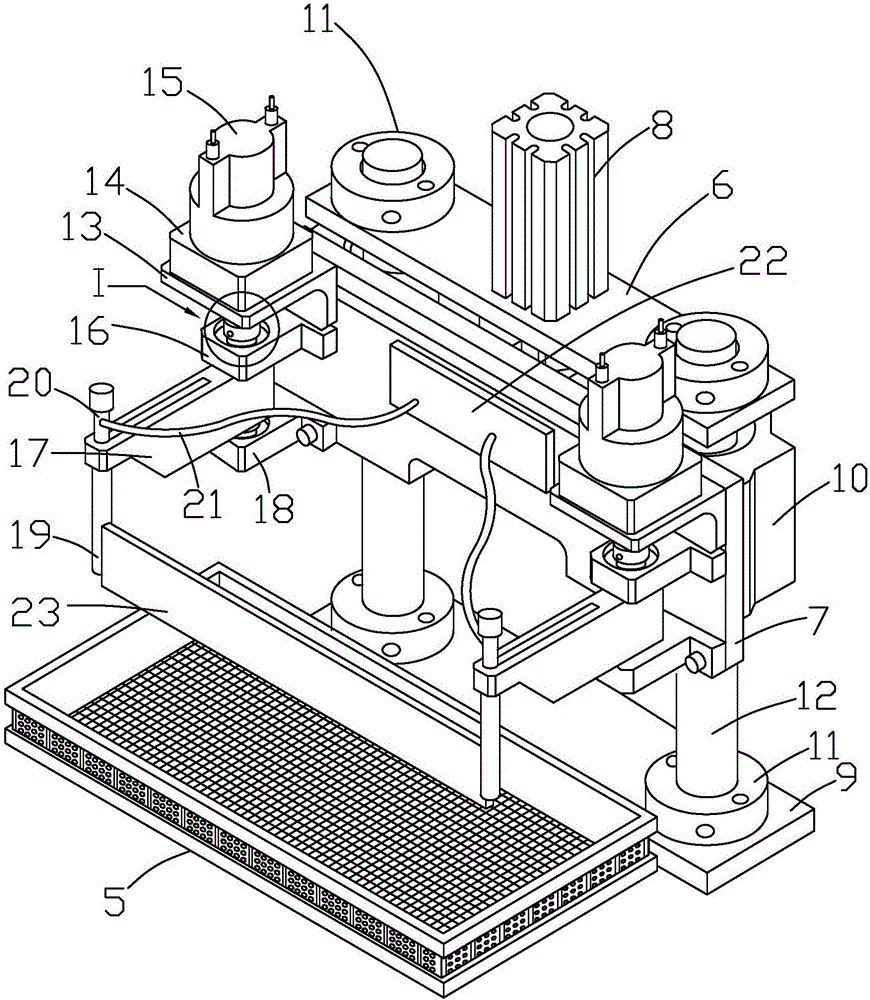

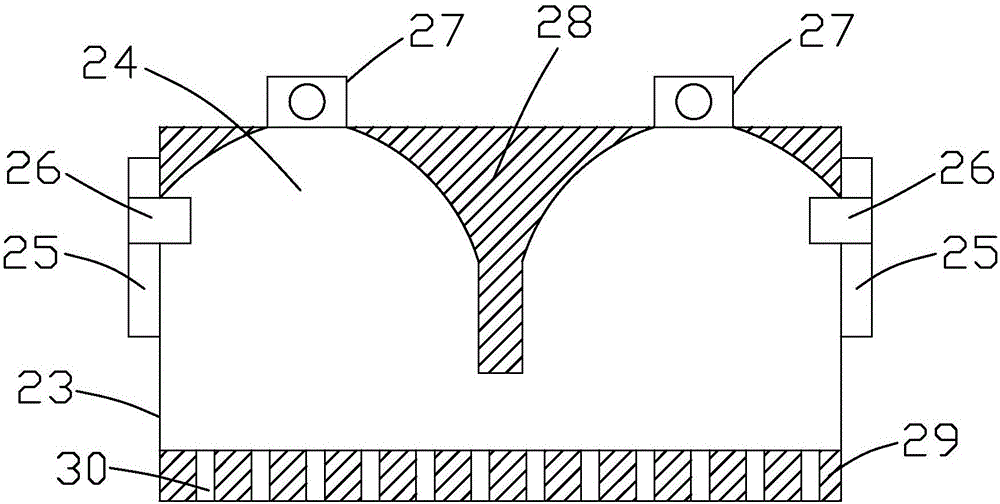

[0047] Such as Figures 1 to 6 As shown, the automatic feeding method based on the square silkworm rearing frame includes the following steps:

[0048] (1) Assembly line installation

[0049] a. First, according to the area of the site, set up the storage area for the silkworm rearing frame, the constant temperature growth area, the feed storage area, the feeding area, the processing area and the finished product area, and clean up each area, and set the location according to the corresponding area Install the corresponding equipment according to the working direction of the assembly line;

[0050] b. Then determine the installation position of the conveyor belt 2 and the moving direction of the conveyor belt 2 between each corresponding area, and determine the length of the conveyor belt 2 according to the size of the site, so that the assembly line processing is formed between the stations in each area to ensure that the conveyor belt 2 and each work station The distance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com