Oil-water separation device for production of plasticizer epoxy soybean oil

An oil-water separation device and a technology for epoxidizing soybean oil, which are applied in the directions of liquid separation, separation methods, chemical instruments and methods, etc., can solve the problems of heavy distillation process load, incomplete oil-water separation, affecting product quality and product yield, etc. To achieve the effect of improving oil-water separation efficiency and improving oil-water separation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

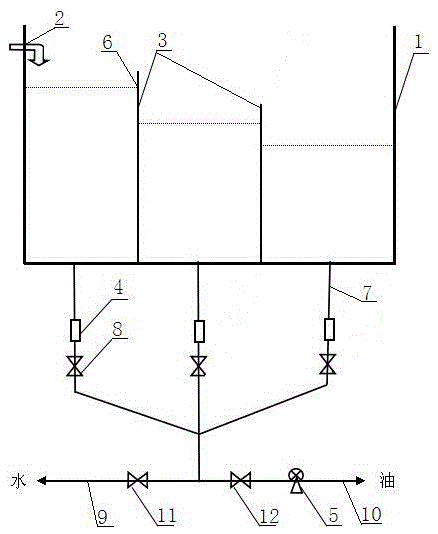

[0008] Such as figure 1 Shown, a kind of oil-water separation device for the production of plasticizer epoxy soybean oil of the present invention, it comprises separation tank 1, feed inlet 2, dividing plate 3, sight cup 4, valve, power pump 5, The upper left side of the separation tank 1 is provided with a feed inlet 2, and the partitions 3 are evenly arranged in the separation tank 1, and the height of the partitions 3 decreases in turn from left to right. Orifice 6, outlet pipe 7 is provided at the bottom of each partition area in separation tank 1, sight cup 4 and pipe valve 8 are installed in turn on outlet pipe 7, and outlet pipe 7 is divided into two pipes of water 9 and oil 10 , the waterway valve 11 is installed on the waterway 9, and the oilway valve 12 and the power pump 5 are installed on the oilway 10.

[0009] During operation, after the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com