Water treatment separation device

A separation equipment and water treatment technology, which is applied in the direction of filtration separation, separation method, mobile filter element filter, etc., can solve the problems of settlement pollution of lower clear water, low efficiency of floc impurity separation, inconvenient water treatment efficiency, etc., to achieve floc Effects of low concentration, reduced probability, and ease of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

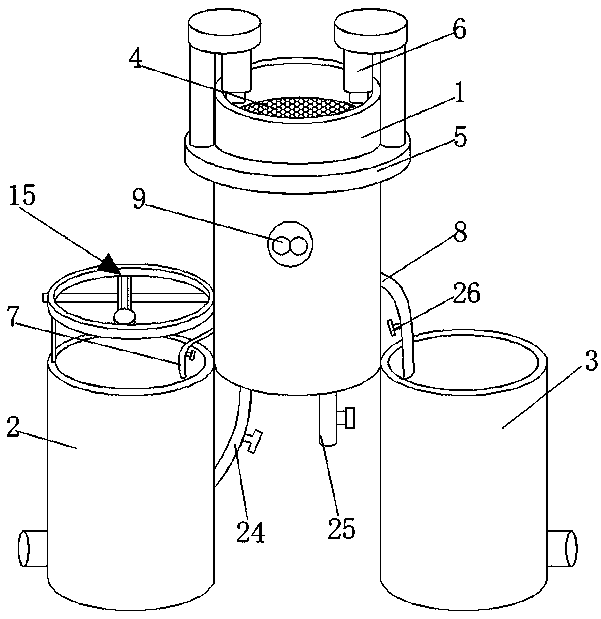

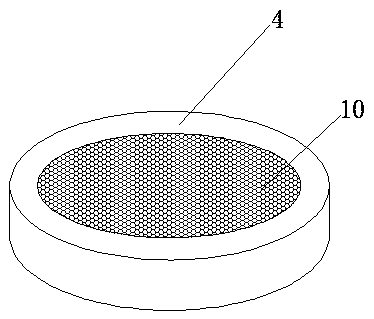

[0030] refer to Figure 1-2 , a water treatment separation equipment, including the first cylinder 1, the second cylinder 2 and the third cylinder 3, and the first cylinder 1, the second cylinder 2 and the third cylinder 3 are in the shape of "pin" Type arrangement, the inner wall of the first cylinder 1 is connected with the first piston 4, the middle part of the first piston 4 is provided with an opening, the inner wall of the opening and the inner wall of the third cylinder 3 are connected with a filter screen 10, the first cylinder 1 The outer wall is sleeved with a fixed ring 5, and the fixed ring 5 is connected with an electric push rod 6 through a pole, and the telescopic end of the electric push rod 6 is connected with the first piston 4, and the outer wall of the first cylinder 1 is connected with a first outlet. The water pipe 7 and the second water outlet pipe 8, and the first water outlet pipe 7 and the second water outlet pipe 8 are arranged above the second cylin...

Embodiment 2

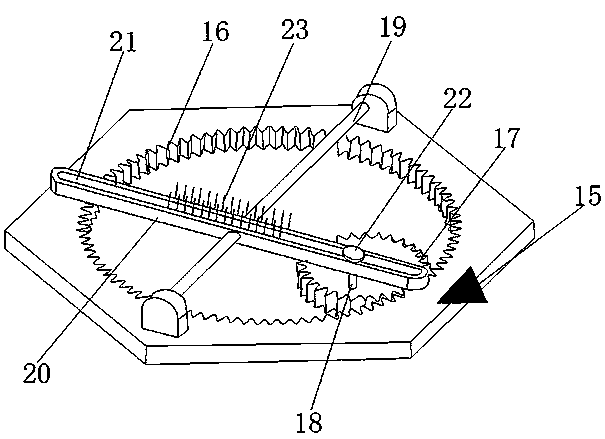

[0032] refer to Figure 1-3 , a water treatment separation device, which is basically the same as that of Embodiment 1, the difference is that the tops of the first cylinder 1 and the second cylinder 2 are connected with a separation assembly 15 through a bracket, and the separation assembly 15 includes a ring gear bar 16 , the ring gear bar 16 is connected with a drive gear 17, and the drive gear 17 is meshed with the ring gear bar 16, the drive gear 17 is connected with a traction shaft 18 near the outer wall of the second cylinder 2, and the traction shaft 18 is arranged on the drive At the edge of the bottom outer wall of the gear 17, the bottom of the ring gear bar 16 is connected with a fixed rod 19 through a support frame, and a reciprocating adjustment plate 20 is also provided under the ring gear bar 16, and the reciprocating adjustment plate 20 is inserted on the fixed rod 19, A chute 21 is opened on the reciprocating adjustment plate 20 , and the traction shaft 18 p...

Embodiment 3

[0034] refer to Figure 1-5 , a kind of water treatment and separation equipment, which is basically the same as that of Embodiment 1, the difference is that the specific material of the first cylinder 1, the second cylinder 2 and the third cylinder 3 is transparent glass, which is convenient for observation, and the first cylinder The bottom of the body 1 is connected with an air outlet pipe 24 and an air return pipe 25, and the end of the air outlet pipe 24 away from the first cylinder body 1 is connected with the second cylinder body 2, and the air outlet pipe 24 and the air return pipe 25 are connected with electromagnetic valves 26. A telescopic rod 11 is connected to the inner wall of the bottom of a cylinder 1, and the outer wall of the telescopic rod 11 is provided with a reset spring 12. The end of the telescopic rod 11 away from the bottom wall of the first cylinder 1 is connected to a second piston 13, and the first cylinder 1 The inner wall of the inner wall is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com