Centrifugal soil remediation device

A centrifugal, soil technology, used in centrifuges, restoration of polluted soil, centrifuges with rotating drums, etc., can solve the problems of low land treatment efficiency and slow screening speed, and achieve fine and uniform mixing. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

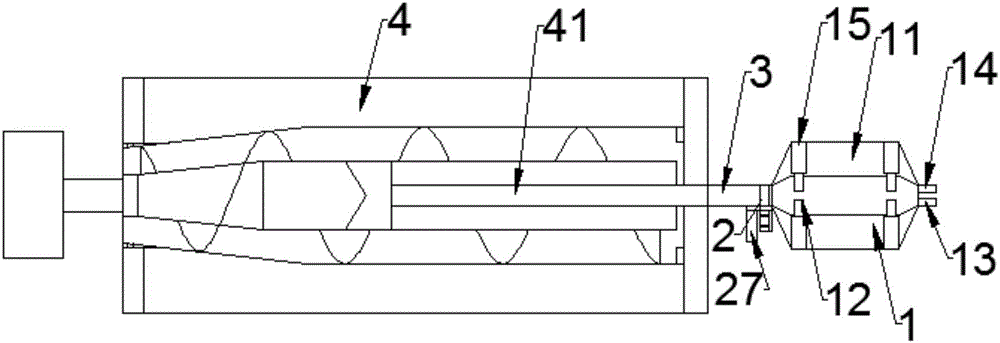

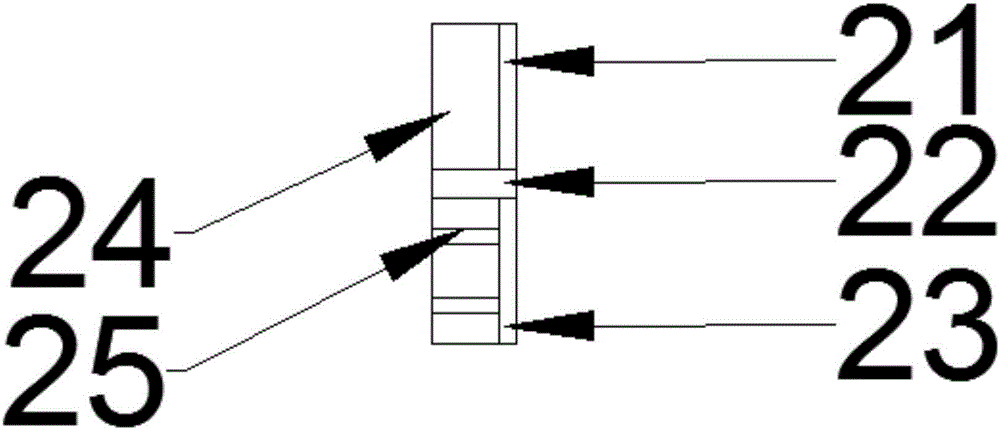

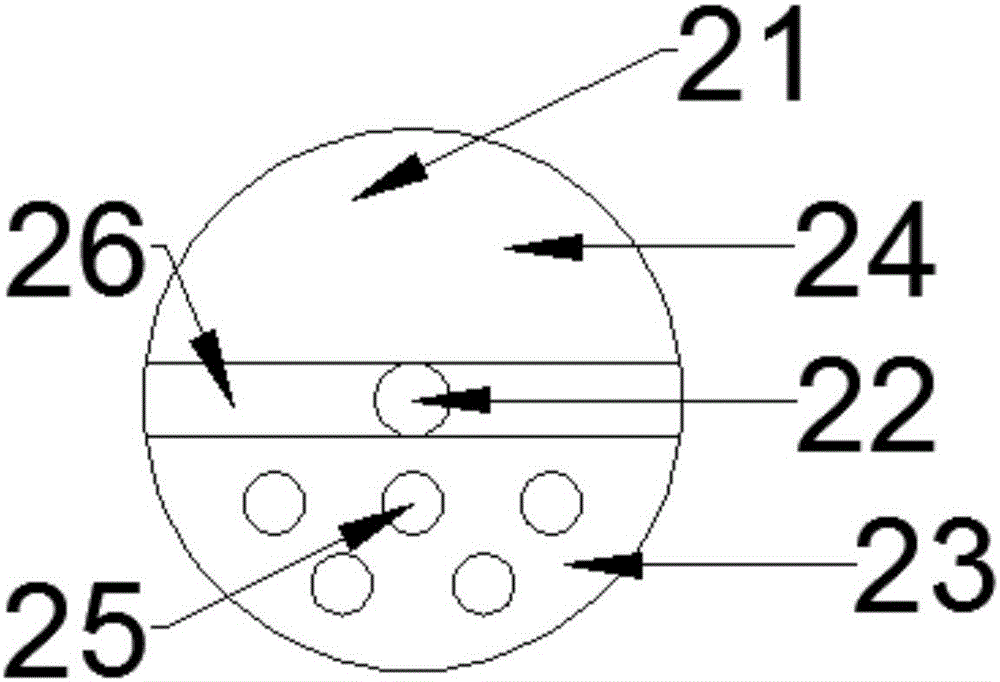

[0020] This embodiment combines figure 1 , figure 2 and image 3 As shown, a centrifugal soil treatment equipment includes a centrifuge 4, a material pipe 3, a filter screen 2, and an ultrasonic agitator 1 connected in sequence, and the ultrasonic agitator 1 is a functional chamber 11 from the outside to the inside. , stirring chamber 12, ultrasonic agitator 1 also includes ultrasonic generator 15 arranged in functional chamber 11, feed pipe 13 and liquid inlet pipe 14 connected to one end of stirring chamber 12; described filter screen 2 includes circular screen mesh 21. A rotating shaft 22 arranged in the center of the circular screen 2, a rotary motor 27 connected to the rotating shaft 22, a partition 26 is arranged in the middle of the filter screen 2, and the partition 26 divides the circular screen 2 into use chambers 24 and 26. The cleaning chamber 23 is connected to the material pipe 3 and the stirring chamber 12 by the two ends of the use chamber 24 . The cleaning ...

Embodiment 2

[0023] This embodiment is further improved based on Embodiment 1, such as figure 1 As shown, the stirring chamber 12, the filter screen 2, the material pipe 3, and the centrifugal pipe 41 are all connected by threads.

[0024] During use, the stirring chamber 12, the filter screen 2, the material pipe 3, and the centrifuge tube 41 are all connected by threads, so that the filter screen 2 and the material pipe 3 are detachable. When they are stuck and cannot be cleaned automatically, use The operator can keep the device working by manual cleaning or replacement.

Embodiment 3

[0026] This embodiment is further improved based on Embodiment 2, combined with figure 2 and image 3 As shown, the mesh aperture of the circular screen 21 is 50um.

[0027] During use, the mesh aperture of the circular screen 21 should not be too large nor too small. Since the material is a mixture of soil and liquid, its viscous force is extremely high. If the mesh aperture is too small, the flow rate of the material is slow and the work efficiency is reduced. , the sieve aperture is large so that smaller diameter stones, etc. can pass through the circular screen 21, thereby damaging the centrifuge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com