Mounting device of laminated glass reaction kettle convenient to move

A technology for installing equipment and laminated glass, applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of easy damage, cracking of glass reactors, and easy breakage of reactors, etc. problem, to achieve fast connection speed, avoid collision or breakage, and simplify the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

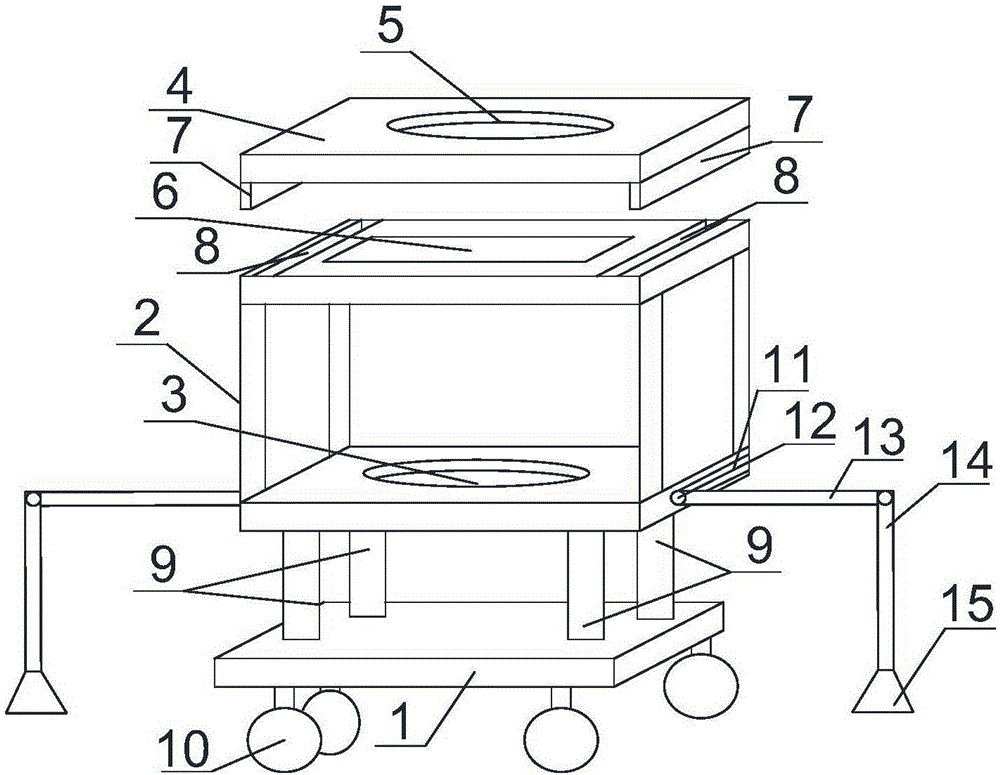

[0021] like figure 1 As shown, the present invention is an installation device for a laminated glass reactor that is easy to move. The first through hole 3 through which the material valve passes, the top of the box body 2 is provided with a cover plate 4 for fixing the lid of the reactor, and the second through hole 5 for passing the lower end of the lid of the reactor is arranged on the cover plate 4, and the box body The top of 2 is provided with the 3rd through-hole 6 that communicates with the 2nd through-hole 5, and the upper end of reactor still body passes through the 3rd through-hole 6 and is connected with the lower end of reactor lid, and the bottom surface both sides of cover plate 4 respectively A protrusion 7 is provided, and the top of the box body 2 is provided with a first groove 8 mated with the protrusion 7 . The box body 2 is arranged as a regular hexahedron structure, and four telescopic columns 9 are connected between the bottom surface of the box body 2...

Embodiment 2

[0024] Based on Embodiment 1, at least two universal rollers 10 are connected below the base 1 . The opposite side surfaces of the box body 2 are respectively provided with a second groove 11, and a fixing device is installed in the second groove 11, and the fixing device includes a fixing rod 12 fixed in the second groove 11, and the fixing rod 12 is connected with a crossbar 13 through a hinge, and the crossbar 13 is movably connected with a support rod 14, and the crossbar 13 and the support rod 14 can be pulled out from the second groove 11 and fixed to each other. When the support rod 14 is pulled out from the second groove 11 and supported on the ground, a suction cup 15 is arranged between the support rod 14 and the ground. The universal roller is used to adjust the position of the whole reactor. When the present invention uses a glass reactor, the reactor needs to be fixed; the principle of use of the fixing device is: when fixing the reactor, pull out the cross bar i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap