Wire bending equipment

A bending and equipment technology, applied in the field of bending machines, can solve the problems of limited bending radius range, inability to quickly and accurately adjust the bending radius in real time, insufficient flexibility, etc., and achieve the effect of convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

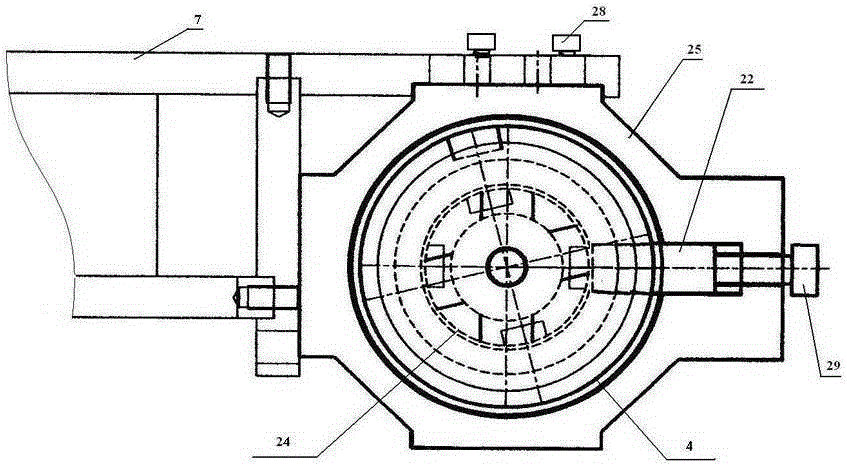

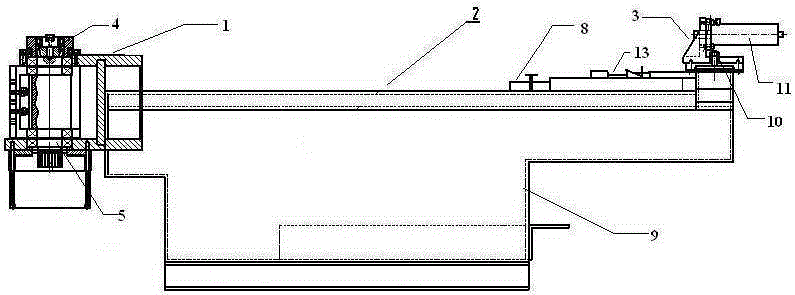

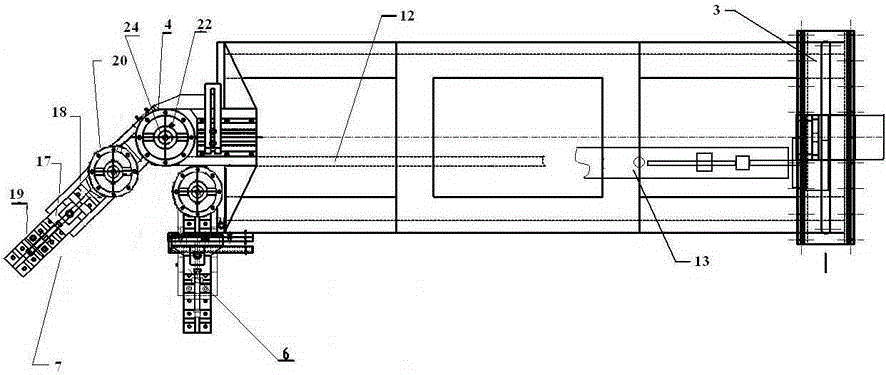

[0027] refer to figure 1 , figure 2 and image 3 As shown, the present invention comprises a machine head 1, a body 2 and a tailstock 3, and the metal wire rod to be bent enters the body 2 through the guide slot hole 21 of the tailstock 3, and after the hydraulic oil cylinder works, the feeding device 13 is in the transmission Rotate under the action of the device 10, the metal wire moves forward after passing through the feeding device 13 and the guide rail mechanism 8, and the front end of the metal wire enters the guide rail groove 12 driven by the feeding device 13, and then enters the arm mold 20 and the bending die 4 In the mold formed, at this moment, the bending die 4 rotates, and the fixed rotating arm 6 and the rotating arm 7 are in a parallel state. After the front end of the metal wire passes through the mold formed by the arm die 20 and the bending die 4, the hydraulic cylinder stops, and then Adjust and fix the fastening mechanism 17 on the sliding bracket 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com